Why Work with Trusted Vacuum Furnaces Manufacturers for Industrial Applications?

1.Introduction

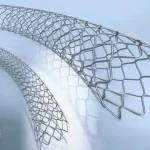

Vacuum furnaces play a vital role in modern manufacturing. From aerospace turbine blades to automotive transmission parts and high-precision medical devices, vacuum technology ensures clean, consistent, and high-quality heat treatment results. These furnaces allow processes such as brazing, sintering, annealing, carburizing, quenching, and tempering to be carried out under controlled vacuum or partial-pressure conditions.

Given the complexity and cost of these industrial systems, choosing the right vacuum furnaces manufacturers is one of the most important decisions a company can make. The difference between working with a trusted supplier and an unreliable one can determine production efficiency, equipment lifespan, and ultimately the profitability of your operations.

2.Why Manufacturer Reliability Matters

When investing in a vacuum furnace, you are not just buying equipment; you are investing in a long-term partnership. Reliable manufacturers provide more than machinery—they deliver consistent quality, technical expertise, and ongoing support.

Unverified or low-quality suppliers may initially appear cost-effective, but hidden costs quickly arise: frequent breakdowns, limited spare parts availability, lack of technical service, and higher rejection rates in production. A trusted manufacturer ensures stability, reduces downtime, and helps you achieve predictable results.

3.Key Benefits of Working with Trusted Manufacturers

Compliance with International Standards:

In global industries like aerospace and medical manufacturing, compliance is non-negotiable. Trusted manufacturers ensure their furnaces meet ISO, CE, and other relevant certifications, making them suitable for international buyers who must pass strict audits and quality checks.

Customized Solutions for Industrial Needs:

No two factories are alike. A trusted vacuum furnace supplier can design and deliver customized solutions tailored to specific applications such as vacuum brazing, powder metallurgy sintering, carburizing, or vacuum annealing. This flexibility helps businesses adapt equipment to their exact production requirements.

Reliable After-Sales Support:

Even the best vacuum furnaces require installation, training, and ongoing maintenance. Trusted manufacturers provide comprehensive after-sales service, including spare parts availability, technical troubleshooting, and process optimization. This ensures minimal downtime and maximizes return on investment.

4.Risks of Choosing Unverified Manufacturers

Choosing the wrong vacuum furnace factory can expose businesses to significant risks:

Poor equipment durability: Low-quality materials lead to faster wear and tear.

Unstable vacuum levels: Resulting in defective parts and wasted materials.

Lack of spare parts and service: Leaving production lines idle for long periods.

Hidden costs: Cheap upfront prices often lead to high long-term expenses.

In industrial manufacturing, these risks can cause delays, loss of contracts, and damage to reputation.

5.Comparing Global vs. Local Vacuum Furnace Manufacturers

When searching for vacuum furnaces manufacturers, companies often weigh the benefits of global versus local suppliers.

Global Brands: Known for decades of experience, wide service networks, and brand reputation. However, they usually come with higher prices and longer delivery times.

Chinese Manufacturers (e.g., SIMUWU): In recent years, China has become a leading hub for vacuum furnace production. Companies like SIMUWU Vacuum Furnace combine competitive pricing with international-level quality and certification, making them attractive choices for overseas buyers.

The key is to evaluate not just cost but also service capability, innovation, and long-term reliability.

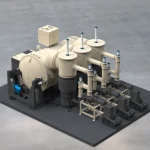

6.Case Example: SIMUWU Vacuum Furnace from China

SIMUWU is a leading vacuum furnace manufacturer in China, specializing in industrial solutions for brazing, sintering, annealing, carburizing, and quenching. With a strong focus on R&D and international standards, SIMUWU furnaces are exported worldwide.

The company’s ability to provide custom vacuum furnace solutions and full technical support sets it apart from smaller factories. For buyers seeking a balance between cost-effectiveness and reliable performance, SIMUWU has become a trusted partner across industries like aerospace, energy, and automotive.

7.Summary: Why Trust Makes the Difference

Industrial vacuum furnaces are not just machines—they are the backbone of precision manufacturing. Working with trusted vacuum furnaces manufacturers ensures that your production processes are stable, efficient, and future-proof.

From consistent quality and advanced technology to compliance and after-sales support, the value of a reliable manufacturer goes far beyond the initial purchase price. Companies that prioritize trust in their suppliers gain a long-term competitive advantage.

8.Frequently Asked Questions (FAQ)

Q: What are the advantages of working with trusted vacuum furnace manufacturers?

A: They provide reliable equipment, advanced technology, and strong after-sales service, reducing production risks and costs.

Q: How can I identify a trusted manufacturer?

A: Look for international certifications, proven project references, customization capability, and comprehensive technical support.

Q: Are Chinese vacuum furnace manufacturers reliable?

A: Yes. Leading companies like SIMUWU meet global standards and provide cost-effective solutions with full service support.

Q: What industries rely most on vacuum furnaces?

A: Aerospace, automotive, electronics, powder metallurgy, energy, and medical device manufacturing.

Q: What risks do I face with unverified suppliers?

A: Equipment breakdowns, unstable processes, lack of service, and higher long-term operational costs.

Q: Do trusted manufacturers offer customized vacuum furnace solutions?

A: Yes. They can design furnaces for specific processes such as vacuum brazing, carburizing, sintering, or annealing.

Q: Is after-sales service really that important?

A: Absolutely. Proper training, spare parts, and maintenance ensure minimal downtime and higher productivity.

Q: How does cost differ between trusted and unverified manufacturers?

A: Trusted suppliers may cost more initially, but they provide better durability, fewer breakdowns, and long-term savings.