Introduction:

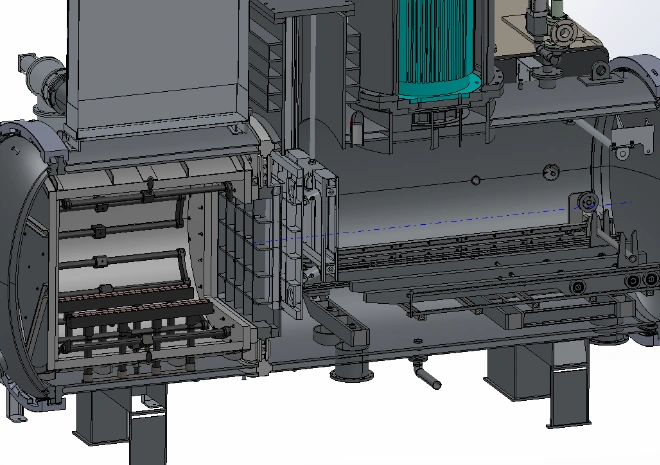

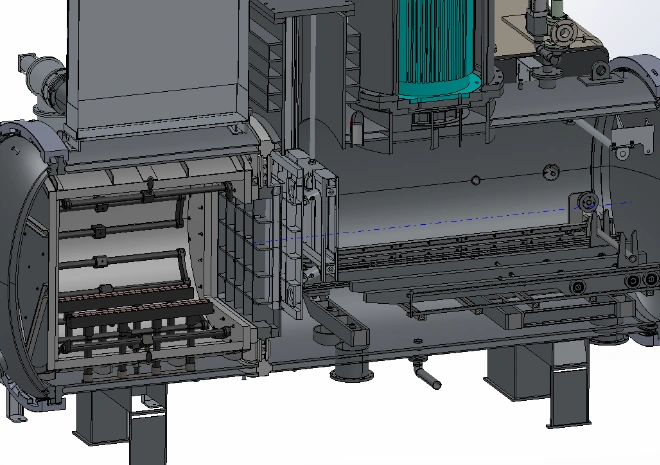

Dual chamber vacuum gas quenching furnace is a vacuum heat treatment equipment with independent spatial layouts for the hot chamber and cold chamber.

In a vacuum environment, workpieces are heated in the hot chamber and quenched in the cold chamber.Workpieces are fed into the cold chamber by an external charging cart. After closing the furnace door, the automatic operation program is activated, and the conveying system automatically transfers the workpieces into the hot chamber for heating.

Once the rated temperature is reached, the workpieces are automatically returned to the cold chamber for quenching. At this point, the temperature of the hot chamber remains at a high range of 700-800°C, which can save 30%-35% of energy consumption for the heating process of subsequent workpieces.

Main Advantage

1.Vacuum environment effectively reduces oxidation and decarburization of workpieces, ensuring excellent surface quality;

2.The independent design of the two chambers significantly shortens cooling time while maintaining the hot chamber temperature at 700-800°C, achieving 30%-35% energy savings and realizing efficient energy reduction;

3.The quenching process is uniform and stable, which can significantly reduce the risk of workpiece deformation and cracking, making it particularly suitable for processing precision parts;

4.Avoiding carburization issues: During vacuum quenching cooling, carburization will further lower the material’s melting point, potentially causing local melting of the surface. However, high-pressure gas quenching can completely eliminate this phenomenon.

Related Configuration

1.Heating Chamber

● Heating Chamber : Circular/Square

● Heating Element : Graphite / Molybdneum

The heating chamber consists of a stainless steel frame, heat insulation layer, heating elements, insulation parts, and a furnace bed. According to customer requirements, heating elements are made of different materials for various scenarios, with a maximum operating temperature of up to 1300℃ and excellent furnace temperature uniformity.

2.Vacuum system

Well-known domestic and foreign vacuum pump brands, such as EVP, Leybold, etc., are matched according to customer needs.

3.Control system

The operation control of this Dual-chamber Vacuum Gas Quenching Furnace is performed by the Siemens S7-1200 programmable logic controller. Interlock protection control is adopted for the equipment’s vacuum pump, valves, heating power supply, cooling fan, and other components. The system can judge and alarm abnormalities occurring during equipment operation, enabling fully automatic control. The network system supports remote network control and data transmission functions.

All low-voltage components use international brands such as Siemens, Schneider, and Phoenix, which are highly reliable in terms of quality, performance, and craftsmanship, reducing the failure rate of the control system.

● The network system supports remote network control and data transmission functions.

● Remote fault diagnosis, remote process debugging, etc.

● Supports software upgrade and update.

4.Other System

Our temperature measurement system adopts a nine-point temperature measurement method to monitor product temperatures in real-time and accurately, ensuring the uniformity of furnace temperature is maintained within the range of ±3℃ – ±5℃.

The pneumatic system supports automated control via a touchscreen, enabling pneumatic control of the entire gas circuit. the inflation system can be set up once with no need for further adjustments, as on-off control is achieved through solenoid valves, making it simple, convenient, and easy to adjust.

An independent water cooling system is equipped, mainly used to control the temperature of the furnace body, vacuum pump, and heating electrodes to maintain the normal operation of the vacuum furnace.

Technical Parameter

| Model |

Effective Working Zone (W*H*L) |

MAX. Temperature |

Ultimate pressure |

Temperature uniformity |

Loading capacity |

| RVGQ-446-2 |

400*400*600mm |

1300℃ |

4*10-1Pa/6.7*10-3Pa |

±5℃ |

200kg |

| RVGQ-557-2 |

500*500*700mm |

1300℃ |

4*10-1Pa/6.7*10-3Pa |

±5℃ |

300kg |

| RVGQ-669-2 |

600*600*900mm |

1300℃ |

4*10-1Pa/6.7*10-3Pa |

±5℃ |

500kg |

| RVGQ-7710-2 |

700*700*1000mm |

1300℃ |

4*10-1Pa/6.7*10-3Pa |

±5℃ |

700kg |

| RVGQ-8812-2 |

800*800*1200mm |

1300℃ |

4*10-1Pa/6.7*10-3Pa |

±5℃ |

1000kg |

| RVGQ-9915-2 |

900*900*1500mm |

1300℃ |

4*10-1Pa/6.7*10-3Pa |

±5℃ |

1200kg |

| Remark: The working zone of equipment could be customized base on customer’s production. |

After-Sales and Acceptance Services

After the completion of production, the manufacturing plant will conduct factory acceptance test, including:

1.Ultimate vacuum test

2.Pressure rise rate test

3.Inspection of the completeness of all equipment systems

After the equipment is delivered to the user’s site, site acceptance test will be carried out, including:

1.Overall installation

2.Overall debugging

3.User training

4.Document handover

Warranty

The warranty period is one year from the date of final acceptance. It covers non-human-damaged components (excluding consumables/wear parts), as well as manual maintenance services and transportation costs incurred during the warranty period.

We have an independent after-sales service department that provides users with timely services and guarantees a 24-hour rapid response.