What Types of Vacuum Heat Treatment Furnaces Are There?

Introduction

Vacuum heat treatment technology is widely used in modern industry to improve the mechanical properties and surface quality of metals. By operating in a controlled vacuum environment, these furnaces can avoid oxidation, ensure stable results, and meet the strict requirements of industries such as aerospace, automotive, and medical manufacturing.

Understanding Vacuum Heat Treatment

In vacuum heat treatment, materials are heated inside a sealed chamber where the air pressure is significantly reduced. This prevents unwanted chemical reactions with oxygen or nitrogen, leading to cleaner surfaces and higher-quality components. It is particularly suitable for applications requiring high precision and reliability.

Main Types of Vacuum Heat Treatment Furnaces

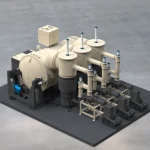

1. Single-Chamber Vacuum Furnace

Compact and flexible, mainly used for processes like annealing, tempering, and solution treatment. Suitable for small-batch production.

2. Multi-Chamber Vacuum Furnace

Designed for higher efficiency, these furnaces have separate heating and cooling chambers. They are commonly used in large-scale production lines.

3. Vacuum Oil Quenching Furnace

Uses oil as a cooling medium. It provides strong hardening effects but requires careful handling to ensure cleanliness.

4. Vacuum Gas Quenching Furnace

Cools components with high-pressure inert gases such as argon or nitrogen. This method is clean, reduces distortion, and is often applied in aerospace and precision industries.

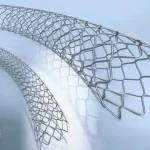

5. Vacuum Brazing Furnace

Specially designed for joining different metals without using flux, producing clean and strong joints. Common in aerospace, electronics, and medical equipment manufacturing.

6. Vacuum Sintering Furnace

Mainly used in powder metallurgy for producing hard alloys, advanced ceramics, and other high-performance materials.

7. High-Pressure Vacuum Furnace

Capable of cooling at pressures up to 20 bar, ensuring uniform mechanical properties and minimal deformation of complex parts.

Choosing the Right Furnace

Each furnace type has its strengths. For instance, single-chamber furnaces are cost-effective for smaller batches, while multi-chamber and high-pressure furnaces are better for mass production. The right choice depends on production needs, material type, and quality requirements.

Typical Applications

Aerospace: Gas quenching and brazing for turbine blades and structural components.

Automotive: Oil quenching and multi-chamber systems for gears, shafts, and engine parts.

Tool & Die Manufacturing: Single-chamber furnaces for hardening and tempering.

Medical Devices: Vacuum brazing and sintering for surgical instruments and implants.

Advantages and Disadvantages of Vacuum Furnaces

Advantages

Oxidation- and contamination-free treatment.

Precise and uniform heating and cooling.

High-quality surface finish.

Adaptability to different alloys and components.

Disadvantages

Higher initial investment compared with conventional furnaces.

More complex maintenance.

Some cooling limitations depending on furnace type.

The Bottom Line

Vacuum heat treatment furnaces play a key role in modern manufacturing, ensuring reliability, quality, and performance across critical industries. Selecting the right furnace type requires balancing process requirements, production scale, and cost considerations.

| Furnace Type | Main Features | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Single-Chamber Vacuum Furnace | Compact design, single process chamber | Tool hardening, small-batch heat treatment | Lower cost, flexible use, good for R&D or small production | Limited productivity, longer cycle times |

| Multi-Chamber Vacuum Furnace | Separate heating & cooling chambers, higher automation | Automotive parts, mass production | High throughput, continuous operation, reduced downtime | Higher investment, complex maintenance |

| Vacuum Oil Quenching Furnace | Uses oil as cooling medium | Gears, shafts, heavy-duty automotive parts | Strong hardening depth, suitable for thicker components | Possible contamination, requires cleaning, limited cleanliness |

| Vacuum Gas Quenching Furnace | Uses high-pressure inert gases (argon, nitrogen, helium) | Aerospace components, medical implants | Clean process, less distortion, precise control | Higher operating cost, slower cooling for thick parts |

| Vacuum Brazing Furnace | Flux-free metal joining under vacuum | Aerospace, electronics, medical devices | Produces clean, strong joints, no flux residue | Requires precise process control, limited to brazing tasks |

| Vacuum Sintering Furnace | For powder metallurgy and ceramics | Hard alloys, advanced ceramics, tungsten carbide | Suitable for complex shapes, high material performance | Limited to specific materials and processes |

| High-Pressure Vacuum Furnace | Cooling under pressure up to 20 bar | High-precision aerospace & automotive parts | Uniform properties, minimal distortion, efficient cooling | Higher equipment cost, larger energy demand |

Comparison of Vacuum Heat Treatment Furnaces

Frequently Asked Questions (FAQ)

Q: What types of vacuum furnaces are commonly used?

A: Single-chamber, multi-chamber, vacuum oil quenching, vacuum gas quenching, brazing, sintering, and high-pressure furnaces.

Q: Why choose vacuum heat treatment over traditional furnaces?

A: It prevents oxidation, improves surface quality, and ensures more precise results.

Q: Which industries benefit most from vacuum furnaces?

A: Aerospace, automotive, tool & die, and medical equipment manufacturing.

Q: How do oil quenching and gas quenching differ?

A: Oil quenching provides stronger hardening but may risk contamination, while gas quenching is cleaner with less distortion.

Q: Are vacuum furnaces suitable for mass production?

A: Yes, especially multi-chamber and high-pressure models designed for continuous processing.