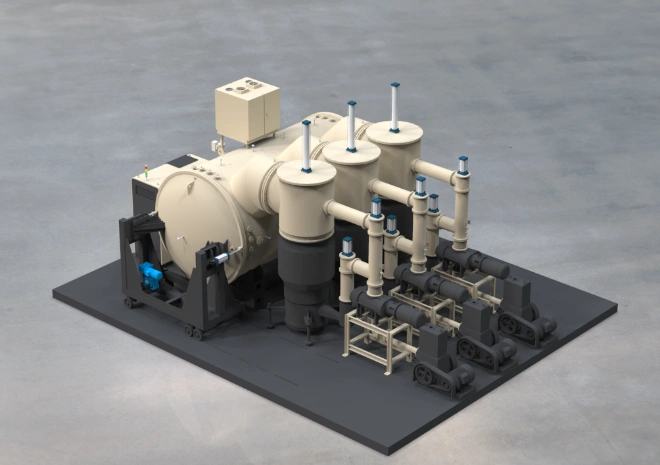

1.Introduction to Vacuum Brazing Equipment

Vacuum brazing equipment plays a pivotal role in joining metal components by melting a filler metal in a vacuum setting, ensuring robust, leak-proof bonds. This method prevents oxidation, minimizes porosity, and boosts joint quality. Two main categories of vacuum brazing furnaces are prevalent in the market, tailored for distinct materials and uses: high-temperature and low-temperature models.

2.Types of Vacuum Brazing Furnaces

High-Temperature Vacuum Brazing Furnaces

Temperature Capability: Capable of reaching very high temperatures.

Key Features:

●Specifically engineered for metals with elevated melting points, such as certain advanced alloys and specialty steels.

●Incorporates advanced cooling systems to endure intense heat.

●Frequently utilized in sectors demanding high-performance materials, like aerospace and energy.

Example Applications:

●Components for jet engines

●Parts for nuclear reactors

●High-duty heat exchangers

Low-Temperature Vacuum Brazing Furnaces

Temperature Capability: Operates at relatively lower temperatures.

Key Features:

●Suited for braze alloys with lower melting points, including various solders.

●Designed for energy efficiency with quick heating and cooling.

●Well-suited for industries like electronics and automotive manufacturing.

Example Applications:

●Packaging for power electronics modules

●Cooling components in electric vehicles

●Heat exchangers made from lightweight metals

3.Key Differences Between High- and Low-Temperature Furnaces

| Feature | High-Temperature Furnaces | Low-Temperature Furnaces |

|---|---|---|

| Max Temperature | Very high | Relatively low |

| Materials Processed | Advanced alloys, specialty steels | Lightweight metals, ceramics |

| Energy Consumption | High (due to intense heat) | Low (efficient for mild conditions) |

| Cycle Time | Longer (gradual heating/cooling) | Shorter (rapid transitions) |

| Cost | Higher investment | More budget-friendly |

4.Applications of High-Temperature Vacuum Brazing Furnaces

Aerospace: Critical engine parts, structural components.

Energy: Components for nuclear facilities, solar energy systems.

Industrial: High-pressure systems, chemical processing gear.

5.Applications of Low-Temperature Vacuum Brazing Furnaces

Automotive: Battery systems, electric motor parts, climate control units.

Electronics: Device packaging, sensor integration, LED production.

Consumer Goods: Kitchenware, lighting solutions, medical instruments.

6.Advantages and Disadvantages of Each Type

High-Temperature Furnaces

Advantages:

●Capable of processing high-strength, heat-tolerant materials.

●Yield joints with excellent resistance to deformation under long-term stress.

Disadvantages:

●Higher operational and maintenance costs.

●Extended production timelines.

Low-Temperature Furnaces

Advantages:

●Cost-effective and energy-saving.

●Well-adapted for large-scale production.

Disadvantages:

●Limited to materials with lower melting points.

●Not suitable for applications subjected to extreme stress or heat.

7.Summary

High-temperature vacuum brazing furnaces are indispensable in sectors like aerospace and energy, where material performance is critical. Conversely, low-temperature models are prevalent in electronics and automotive industries, offering efficiency and cost-effectiveness. The selection hinges on material requirements, budget, and production scale.

8.Frequently Asked Questions (FAQ)

Q: What sets high- and low-temperature vacuum brazing furnaces apart?

A: High-temperature units are designed for advanced alloys, while low-temperature ones cater to lighter metals, with differences in temperature range, energy use, and cost.

Q: Which sectors depend on high-temperature vacuum brazing?

A: Industries such as aerospace, nuclear energy, and specialized industrial applications.

Q: Why might a manufacturer opt for a low-temperature furnace?

A: For its cost efficiency, swift production cycles, and compatibility with a range of softer materials.

Q: How do the costs of high- and low-temperature furnaces compare?

A: High-temperature furnaces entail a higher initial and operational cost due to their sophisticated design and energy needs.

Q: Is stainless steel suitable for low-temperature brazing?

A: No, it typically requires the higher temperatures achievable with high-temperature furnaces.

Q: What’s the main benefit of vacuum brazing over other methods?

A: It prevents oxidation, leading to stronger, cleaner joint formations.

Q: Are low-temperature furnaces apt for mass production?

A: Yes, their rapid cycle times make them ideal for high-volume manufacturing scenarios.

Q: What safety aspects should be considered with high-temperature furnaces?

A: Precautions against thermal hazards and safe handling of heated components are essential.

Q: Do low-temperature furnaces utilize lead-based materials?

A: While some may, many now employ lead-free alternatives for environmental and health reasons.

Q: Can a single furnace handle both high- and low-temperature brazing?

A: No, specialized furnaces are necessary for each temperature range to maintain performance standards.