1.Introduction

Vacum tempering furnace is an advanced heat treatment equipment designed to temper metal parts in vacuum environment. This process improves material toughness, relieves internal stress, and enhances overall performance without causing surface oxidation or contamination.

2.Understanding Vacuum Tempering: The Key to Material Improvement

Tempering is a heat treatment step that follows quenching. In vacuum tempering furnace, the absence of oxygen prevents oxidation, ensuring a bright, clean finish and preserving the metal’s mechanical properties.

3.Why Use Vacuum Tempering Furnace?

The vacuum environment minimizes contamination, keeps surfaces oxide-free, and reduces the need for post-process cleaning. It also provides precise temperature control, which is essential for high-precision components.

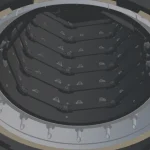

4.How Does Vacuum Tempering Furnace Work?

The vacuum tempering furnace process starts by placing parts in a sealed chamber, which is then evacuated. The furnace heats to the desired tempering temperature (150°C–650°C) with uniform distribution, allowing consistent results and improved energy efficiency.

5.Applications of Vacuum Tempering Furnaces

Industrial vacuum tempering furnaces are widely used for aerospace parts, automotive gears, molds, bearings, and high-speed steel tools. These industries value vacuum tempering for its ability to maintain dimensional accuracy and surface quality.

6.Advantages of Vacuum Tempering over Conventional Methods

Vacuum tempering eliminates oxidation, delivers uniform hardness, and produces a bright finish. This reduces post-processing steps, saving time and cost for manufacturers.

7.Conclusion

Vacuum tempering furnace is a crucial solution for manufacturers that demand precision, clean surfaces, and reliable mechanical properties. Its ability to temper components without oxidation or scaling makes it ideal for industries such as aerospace, automotive, and tooling. By using vacuum tempering furnace, companies can achieve higher quality results, reduce waste, and optimize production efficiency.

8.Frequently Asked Questions (FAQ)

Q: What is the difference between vacuum tempering and conventional tempering?

A: Vacuum tempering is done in a controlled vacuum atmosphere, resulting in a clean, oxide-free surface, while conventional tempering in air may cause scaling.

Q: Can vacuum tempering be used for all metals?

A: It is ideal for steels and alloys that require precise hardness control, such as tool steels, high-speed steels, and stainless steels.

Q: Why is vacuum atmosphere better for tempering?

A: The vacuum prevents oxidation and decarburization, which preserves mechanical properties and ensures consistent results.

Q: How do vacuum furnaces reduce energy consumption?

A: They offer better heat transfer efficiency and optimized heating cycles, lowering overall energy use.

Q: What are common materials treated in vacuum tempering furnaces?

A: Hardened steel parts, gears, molds, bearings, and precision tools.