Vacuum heat treatment ensures zero oxidation and minimal distortion, making it essential for high-precision manufacturing. This guide explores its core mechanisms, industrial applications and maintenance.

Table of Contents

- 1. Defining Vacuum Heat Treatment

- 2. Core Principles and Mechanisms

- 3. Technical Advantages Over Conventional Methods

- 4. Industrial Applications and Case Studies

- 5. Common Challenges and Maintenance

- 6. Frequently Asked Questions (FAQ)

1. Defining Vacuum Heat Treatment

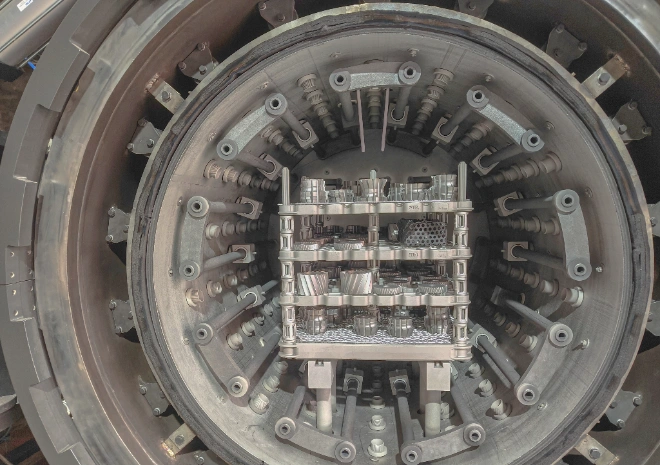

Vacuum heat treatment is a material processing technology that integrates vacuum environments with thermal treatment processes. By heating metals or alloys in a controlled vacuum (ranging from low to ultra-high vacuum, below 1 atm), it eliminates oxidation, decarburization, and carburization risks, resulting in cleaner surfaces and improved material properties.

Unlike conventional methods, vacuum treatment operates without protective atmospheres, relying instead on vacuum-induced inertia to prevent chemical reactions. This enables precise control over heating, cooling, and phase transformations, making it ideal for high-performance components.

2. Core Principles and Mechanisms

2.1 Thermal Dynamics in Vacuum

Heat Transfer Efficiency:

Reduced gas molecules in vacuum minimize convective resistance, accelerating heat transfer. For example, vacuum furnaces achieve uniform temperatures (±5℃) using PID-controlled systems.

Surface Purification:

Vacuum environments volatilize surface contaminants like oil and rust, achieving surface roughness as fine as Ra0.4μm without manual polishing.

2.2 Phase Transformation Control

Quenching Techniques:

High-pressure gas quenching (e.g., 1–2 MPa nitrogen) cools workpieces rapidly, enabling hardening of thick sections (up to 100mm in high-alloy steels). Oil quenching is preferred for complex shapes to minimize distortion.

Diffusion Processes:

Vacuum enables controlled gas injection for nitriding (e.g., 530–560℃ with ammonia) and carbonitriding, producing hardened layers (20–80μm) with high toughness (up to 1700HV for Cr25% alloys).

3. Technical Advantages Over Conventional Methods

| Parameter | Vacuum Heat Treatment | Conventional Methods |

|---|---|---|

| Surface Quality | Oxide-free, Ra0.4μm finish | Oxidized, requires post-treatment |

| Distortion Control | Minimal deformation (e.g., H13 steel) | High risk of cracking |

| Process Flexibility | Supports quenching, tempering, brazing | Limited to air/oil quenching |

| Environmental Impact | Zero emissions | Releases harmful gases |

Case Study:

A 5-ton H13 steel die-casting mold treated via vacuum quenching (1.5 MPa nitrogen) exhibited 30% higher fatigue life and zero cracking, compared to salt-bath quenching.

4. Industrial Applications and Case Studies

Turbine Blades:

Inconel 718 blades vacuum-solid-solution-treated at 1120℃ achieve 30% greater high-temperature strength.

Gear Components:

Vacuum-carburized gears reduce wear rates by 40% compared to gas carburizing.

Surgical Implants:

Titanium alloys processed in vacuum exhibit 99.9% purity, meeting biocompatibility standards.

H13 Steel Molds:

Vacuum-treated molds last 3× longer than conventionally treated ones, with 50% reduced grinding allowances.

5. Common Challenges and Maintenance

5.1 Equipment Issues

Vacuum Leaks:

Regularly inspect O-rings and door seals; replace worn components.

Heating Element Failure:

Monitor resistance wires for cracks; replace every 2–3 years.

5.2 Process Optimization

Cooling Rate Calibration:

Use thermal imaging to verify gas flow uniformity.

Software Glitches:

Update PLC programs annually and maintain backup logs.

Preventive Maintenance:

Implement a 500-hour checklist for pump oil replacement, filter cleaning, and thermal couple calibration.

6.Frequently Asked Questions (FAQ)

Q: What distinguishes vacuum heat treatment from conventional methods?

A: Vacuum treatment eliminates oxidation/decarburization, enables precise phase control, and reduces post-processing .

Q: Which industries rely heavily on vacuum heat treatment?

A: Aerospace , automotive , medical, and tooling .

Q: Why choose vacuum over conventional for high-precision parts?

A: Superior surface finish , minimal distortion, and enhanced fatigue resistance.

Q: How does vacuum nitriding improve material performance?

A: Produces ε-phase nitride layers with high toughness and no brittle “white layer”.

Q: What are the limitations of vacuum heat treatment?

A: Higher equipment costs, slower cooling for thick sections, and sensitivity to power interruptions.

Q: Can vacuum treatment handle large workpieces?

A: Yes, dual-chamber furnaces with 2000kPa gas quenching can process dense loads.

Q: What materials benefit most from vacuum processes?

A: High-alloy steels, titanium alloys, and stainless steels prone to intergranular oxidation.

Q: How does vacuum brazing compare to torch brazing?

A: Vacuum brazing ensures void-free joints without flux residues.

Q: What safety measures are critical for vacuum furnaces?

A: Explosion-proof designs, hydrogen sensors, and automatic pressure relief valves.

Q: Is vacuum heat treatment cost-effective for mass production?

A: Yes, for high-value parts where quality outweighs initial setup costs.

By merging vacuum science with thermal engineering, this technology redefines material performance limits, offering a cleaner, more precise alternative to traditional methods.

To better understand how vacuum heat treatment is applied in steel processing and industrial manufacturing, please refer to [About Vacuum Heat Treatment]. If you require further assistance, feel free to contact us for professional consultation.