1. Introduction

Vacuum gas quenching furnace is an advanced heat treatment system that uses a controlled vacuum and gas flow to cool metal parts rapidly after they have been heated to high temperatures. This process is designed to harden materials, improve their mechanical properties, and reduce distortion, all while maintaining a clean, oxide-free surface.

2. Understanding Vacuum Gas Quenching: The Key to Material Hardening

Gas quenching is a heat treatment process that involves cooling heated parts using gas rather than traditional methods like water or oil. In Vacuum gas quenching furnace, the process takes place in Vacuum, which eliminates the risk of oxidation and contamination. The absence of oxygen ensures that the material’s surface remains clean, which is crucial for high-quality components.

3. Why Use Vacuum Gas Quenching Furnace?

The primary reason industries use vacuum gas quenching furnace is its ability to rapidly and uniformly cool parts without causing oxidation or distortion. The vacuum atmosphere reduces the risk of harmful reactions, ensuring that parts retain their mechanical properties. Additionally, using gas for cooling allows for precise control of cooling rates, which is essential for achieving desired hardness and toughness.

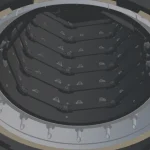

4. How Does Vacuum Gas Quenching Furnace Work?

The process starts with placing the parts in a sealed chamber within the vacuum furnace. After heating the parts to the desired temperature, the vacuum is created to remove air and any contaminants. Then, a controlled flow of gas, typically nitrogen or argon, is used to cool the parts rapidly. The uniform gas flow ensures that the parts cool evenly, preventing any warping or cracking, and ensuring consistency in the hardness and toughness of the material.

5. Applications of Vacuum Gas Quenching Furnaces

Vacuum gas quenching furnaces are used in industries that require precise heat treatment for parts that need to maintain high strength and dimensional accuracy. Common applications include:

Aerospace components

Automotive gears and transmission parts

Medical tools and implants

High-speed steel tools and cutting instruments

These industries rely on vacuum gas quenching for its ability to achieve a clean surface and prevent oxidation during the cooling process.

6. Advantages of Vacuum Gas Quenching over Conventional Methods

The advantages of vacuum gas quenching are numerous:

No Oxidation: Unlike traditional quenching in water or oil, vacuum gas quenching ensures that parts are free from oxidation, which is crucial for components with precise tolerances.

Uniform Cooling: The controlled gas flow results in even cooling rates, reducing the risk of warping or cracking.

Faster Cooling: Gas cooling allows for quicker, more efficient heat treatment compared to traditional quenching methods.

Cleaner Surface: The vacuum environment keeps parts clean, reducing the need for additional cleaning processes after treatment.

7. Conclusion

Vacuum gas quenching furnace offers an ideal solution for manufacturers who need high precision and clean, high-performance parts. The ability to control the cooling rate in vacuum atmosphere ensures that parts maintain their mechanical properties, while avoiding the common issues associated with conventional quenching methods. With its advantages in surface quality, cooling efficiency, and material consistency, vacuum gas quenching furnace is essential for industries such as aerospace, automotive, and tooling.

8.Technical Parameter

| Model | Effective Working Zone (W*H*L) | MAX Temperature | Cooling Gas Pressure |

Ultimate Pressure | Temperature Uniformity |

Loading Capacity |

| RVGQ-446 | 400*400*600mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 200Kg |

| RVGQ-557 | 500*500*700mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 300Kg |

| RVGQ-669 | 600*600*900mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 500Kg |

| RVGQ-7710 | 700*700*1000mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 700Kg |

| RVGQ-8810 | 800*800*1000mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 1000Kg |

| RVGQ-8812 | 800*800*1200mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 1000Kg |

| RVGQ-9915 | 900*900*1500mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 1200Kg |

| RVGQ-101015 | 1000*1000*1500mm | 1300℃ | 6/10/15Bar | 4*10⁻¹Pa /6.7*10⁻³Pa | ±5℃ | 2000Kg |

| Remark:The working zone of equipment could be customized base on customer’s production. | ||||||

9. Frequently Asked Questions (FAQ)

Q: What is the difference between vacuum gas quenching and traditional quenching methods?

A: Traditional quenching involves rapid cooling using water, oil, or air, which may cause oxidation or contamination. Vacuum gas quenching, on the other hand, uses an inert gas in vacuum to cool parts, ensuring a clean, oxide-free surface and more uniform cooling.

Q: What types of materials are typically treated in vacuum gas quenching furnace?

A: Vacuum gas quenching is commonly used for high-strength steels, tool steels, aerospace alloys, and automotive parts that require precise heat treatment and minimal distortion.

Q: How does vacuum gas quenching help prevent distortion?

A: By controlling the gas flow and cooling rates in vacuum, the furnace ensures uniform temperature distribution, which helps prevent warping or cracking of the parts during the cooling process.

Q: Why is vacuum atmosphere better for gas quenching?

A: The vacuum atmosphere eliminates the presence of oxygen, which prevents oxidation of parts. This is especially important for high-performance materials where surface quality is crucial.

Q: What are the main gases used in vacuum gas quenching?

A: The most commonly used gases are nitrogen and argon, which are inert and provide efficient cooling without reacting with the material being treated.