1. Introduction: What Is Vacuum Brazing?

Vacuum brazing is a precision metal joining process that takes place in a vacuum or controlled atmosphere. By removing oxygen and other gases, it ensures that filler metals flow smoothly into joints, forming strong, clean metallurgical bonds without contamination or oxidation.

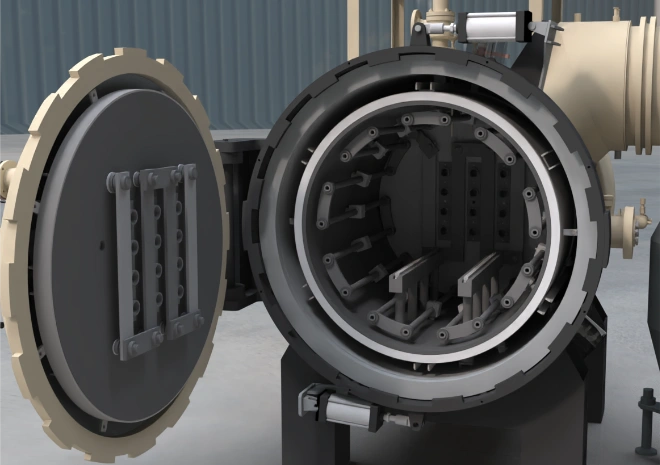

Click the image to view [Low Temperature Vacuum Brazing Furnace]

2. What Is Vacuum Brazing Furnace?

Vacuum brazing furnace is specialized industrial equipment designed to heat components in a vacuum chamber to the point where the filler metal melts and bonds parts together. The furnace provides controlled heating, precise atmosphere management, and uniform temperature distribution, making it ideal for high-quality, repeatable brazing.

3. Step-by-Step Working Principle of Vacuum Brazing Furnace

3.1 Loading Components and Evacuating the Chamber

Components are placed on fixtures inside the furnace. The vacuum system removes air and moisture to reach the target vacuum level, preventing oxidation and contamination.

3.2 Heating and Soaking

Heating elements gradually raise the temperature according to a programmed profile. Soaking at the target temperature ensures uniform heat penetration and prepares the filler metal for brazing.

3.3 The Vacuum Brazing Process

Through a precision metal joining process, once the filler metal melts in the vacuum environment, it flows into gaps and crevices through capillary action. The absence of oxygen prevents oxidation, ensuring clean and strong joints with consistent metallurgical properties.

3.4 Cooling and Unloading

After brazing, the furnace cools the components under vacuum or inert gas. Once safe, parts are removed, ready for use without the need for post-processing or cleaning.

4. The Role of the Vacuum Environment in Brazing

- Prevents oxidation: Maintains joint surface quality

- Reduces inclusions: Improves mechanical strength

- Enhances wettability: Ensures uniform filler metal flow

- Ensures repeatability: Guarantees consistent quality for batch production

5. Advantages of Vacuum Brazing Technology

- Clean, flux-free, oxide-free joints

- High dimensional accuracy and minimal distortion

- Strong metallurgical bonds

- Suitable for sensitive or reactive metals

- Reduces post-processing, scrap, and rework

6. Industrial Applications of Vacuum Brazing

Vacuum brazing furnaces are used across multiple industries:

- Aerospace: Engine components, heat exchangers

- Electronics: Metal-ceramic assemblies, heat sinks

- Automotive: Precision assemblies and components

- Tooling and machinery: Carbide tools, cutting inserts

7. Key Considerations When Selecting Vacuum Brazing Furnace

- Furnace size and capacity

- Maximum operating temperature and temperature uniformity

- Vacuum level and atmosphere control

- Automation and control system capabilities

- Energy efficiency and maintenance requirements

8. Summary

Vacuum brazing furnace enables precise, high-quality joining of metal components through controlled heating and vacuum brazing principles. By maintaining a vacuum environment, it eliminates oxidation, ensures strong metallurgical bonds, and delivers repeatable results suitable for various industrial applications.

Click the image to view [High Temperature Vacuum Brazing Furnace]

9. Frequently Asked Questions (FAQ)

Q: What is the main difference between vacuum brazing and conventional brazing?

A: Vacuum brazing uses a vacuum environment to prevent oxidation and contamination, producing cleaner, stronger joints.

Q: How does vacuum brazing furnace work?

A: Components are loaded, the chamber is evacuated, the furnace heats to the brazing temperature, filler metal melts and flows into joints, and finally parts are cooled under vacuum or inert gas.

Q: What are the benefits of brazing under vacuum?

A: Prevents oxidation, improves joint strength, ensures uniform filler flow, and eliminates post-processing.

Q: Can vacuum brazing handle different types of metals?

A: Yes, it works with a wide range of metals, including stainless steel, titanium, copper, nickel alloys, and more.

Q: Is vacuum brazing suitable for large-scale production?

A: Yes, automated vacuum brazing furnaces can handle batch or continuous production efficiently.

Q: What temperature range does vacuum brazing furnace operate in?

A: Typically between 850°C and 1250°C, depending on filler metal and base material.