Vacuum brazing is a top-tier joining technology. Using advanced vacuum furnaces to prevent oxidation and promote capillary action. This article covers the core principles, equipment benefits, and industrial applications of vacuum brazing.

Table of Contents

- 1. Introduction to Vacuum Brazing

- 2. Technical Principles of Vacuum Brazing Furnaces

- 3. Advantages of Vacuum Brazing

- 4. Applications Across Industries

- 5. Summary

- 6. Frequently Asked Questions (FAQ)

1. Introduction to Vacuum Brazing

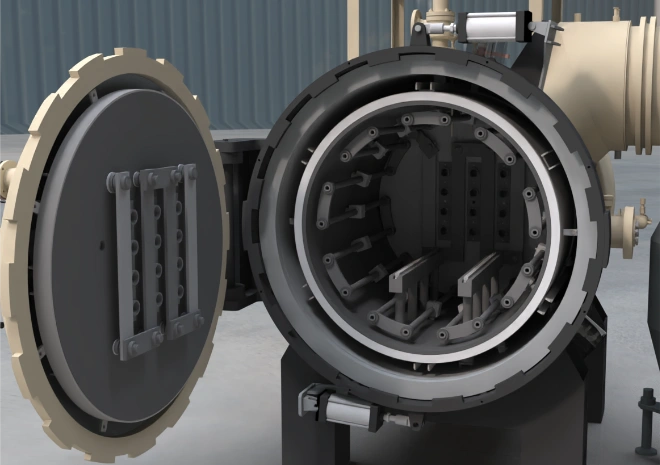

Vacuum brazing is a specialized welding process that joins materials in a controlled vacuum environment. By eliminating oxygen and impurities, this technique achieves high-strength, defect-free bonds, making it critical for industries requiring precision and relibility. Vacuum brazing furnaces are the core equipment enabling this process, combining advanced vacuum systems, heating technologies, and automation to deliver consistent results.

2. Technical Principles of Vacuum Brazing Furnaces

2.1 Vacuum Environment Creation

Vacuum furnaces use multi-stage pump systems (mechanical pumps, diffusion pumps, and Roots pumps) to evacuate air from the chamber, reaching ultra-high vacuum levels (up to 5.0×10⁻⁴ Pa or lowe). This removes oxygen, water vapor, and other contaminants, preventing oxidation and ensuring a clean welding surface.

2.2 Heating Systems and Temperature Control

Resistance, Induction, or Radiation Heating:

Furnaces employ precise heating methods to uniformly raise temperatures from 100°C to 2300°C, accommodating diverse materials like stainless steel, titanium, and ceramics.

PLC and Touchscreen Controls:

Automated systems regulate heating rates, soak times, and cooling cycles, ensuring repeatability and minimizing human error.

2.3 Wetting and Bonding Mechanisms

Melting the Brazing Alloy:

At elevated temperatures, the filler metal (e.g., silver-based or nickel-based alloys) melts while the base materials remain solid.

Capillary Action:

The liquid filler spreads into joints via surface tension and capillary forces, forming a uniform wetting layer.

Diffusion Bonding:

During cooling, atoms from the filler and base metals interdiffuse, creating a metallurgical bond with superior strength.

3. Advantages of Vacuum Brazing

3.1 Oxidation Prevention and Purity

The vacuum environment eliminates oxidation, discoloration, and porosity, resulting in clean, corrosion-resistant joints ideal for aerospace and medical applications.

3.2 Enhanced Joint Strength and Quality

Uniform Temperature Distribution:

Zoned heating ensures consistent thermal profiles, reducing thermal stress and distortion.

High Vacuum Integrity:

Contaminant-free conditions enable stronger interfacial bonds compared to flux-based or atmospheric brazing.

3.3 Versatility in Material Compatibility

Vacuum furnaces handle dissimilar metals (e.g., aluminum-to-steel), heat-sensitive alloys, and ceramics, making them indispensable for complex assemblies.

4. Applications Across Industries

4.1 Aerospace and Aviation

Turbine Blades and Engine Components:

Vacuum brazing joins superalloys without compromising high-temperature performance.

Structural Assemblies:

Lightweight, high-strength joints in fuselages and landing gear benefit from reduced weight and improved fatigue resistance.

4.2 Electronics and Semiconductor Manufacturing

Hermetic Sealing:

Vacuum brazing creates airtight packages for sensors, lasers, and microwave components.

Miniaturized Devices:

Precision bonding enables compact designs in consumer electronics and IoT devices.

4.3 Medical Devices and Automotive Engineering

Implants and Surgical Tools:

Biocompatible, corrosion-free joints meet stringent medical standards.

Heat Exchangers and Fuel Systems:

Vacuum brazing ensures leak-proof connections in automotive radiators and hydrogen fuel cells.

If you’d like to explore more application scenarios, please click here.

5. Summary

Vacuum brazing furnaces leverage controlled environments and advanced heating systems to produce high-quality, reliable joints. Their ability to eliminate oxidation, accommodate diverse materials, and integrate automation makes them essential for aerospace, electronics, and medical industries. As manufacturing demands evolve, vacuum brazing will continue to drive innovation in precision engineering.

6. Frequently Asked Questions (FAQ)

Q: What distinguishes vacuum brazing from traditional brazing methods?

A: Vacuum brazing eliminates flux and atmospheric contaminants, resulting in cleaner, stronger joints with no post-weld cleaning required.

Q: Which industries rely most on vacuum brazing furnaces?

A: Aerospace (engine components), electronics (hermetic seals), and medical devices (implants) are primary users.

Q: Why is temperature control critical in vacuum brazing?

A: Precise temperature management prevents thermal distortion, ensures filler metal flow, and optimizes diffusion bonding.

Q: Can vacuum brazing join dissimilar metals?

A: Yes, it excels at bonding materials with differing melting points, such as aluminum to steel, without intermetallic formation.

Q: What are the limitations of vacuum brazing?

A: High equipment costs, longer cycle times, and size constraints for large parts are key drawbacks.

Q: How does vacuum pressure affect brazing quality?

A: Lower pressures reduce gas solubility in the filler metal, minimizing porosity and enhancing joint integrity.

Q: What filler metals are commonly used in vacuum brazing?

A: Silver-based (BAg series), copper-based (BCuP), and nickel-based (BNi) alloys are popular choices.

Q: Is vacuum brazing environmentally friendly?

A: Yes, it eliminates flux chemicals and reduces scrap rates, aligning with sustainable manufacturing practices.

For insights on how to choose the right Vacuum Brazing Furnace for your needs, feel free to browse [How to Choose the Right Vacuum Brazing Furnace].