1.Understanding the Purpose of the Vacuum Furnace

The vacuum furnace is an essential tool in modern industry. The purpose of the vacuum furnace is to provide an oxygen-free environment where metals can be processed with high precision. Compared to traditional furnaces, the vacuum furnace allows better control over heat treatment, ensuring consistent quality, improved mechanical properties, and superior surface finish.

2.How the Vacuum Furnace Works

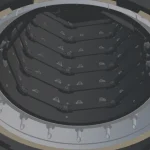

At its core, the vacuum furnace creates a sealed chamber where air and contaminants are removed. By eliminating oxygen, the vacuum heat treatment furnace prevents oxidation, contamination, and scaling of metals during heating. This ensures that sensitive materials, such as aerospace alloys and medical-grade components, maintain their integrity and performance.

3.Practical Benefits of the Vacuum Furnace

- Improved Mechanical Properties – Metals treated in the vacuum furnace achieve greater hardness, strength, and fatigue resistance.

- Oxidation Prevention – The oxygen-free environment ensures surfaces remain clean and bright.

- Precision Heat Treatment – The vacuum heat treatment furnace allows uniform heating and controlled cooling cycles.

- Material Versatility – From tool steels to titanium alloys, the vacuum furnace is used across industries.

4.Why the Vacuum Furnace Is Not Used Everywhere

Although the vacuum furnace has many benefits, it also faces challenges:

- Higher Costs – Equipment and operational costs are higher than traditional furnaces.

- Complex Maintenance – The vacuum furnace requires skilled operation and careful maintenance.

- Limited Scale – Not always cost-effective for mass-production of low-value components.

5.Where the Vacuum Furnace Excels

Aerospace Industry – For jet engine parts and turbine blades requiring extreme durability.

Automotive Components – Precision gears, bearings, and fuel injection systems.

Medical Applications – Surgical instruments and implants that demand perfect cleanliness.

Tooling and Die Making – To increase wear resistance and extend tool life.

6.Advantages and Disadvantages of the Vacuum Furnace

Advantages

- High-quality, contamination-free heat treatment

- Superior mechanical properties

- Excellent for high-performance alloys

Disadvantages

- High equipment and operating cost

- Requires technical expertise

- Limited use in low-cost mass production

7.The Bottom Line

The purpose of the vacuum furnace is clear: it enables high-quality, oxidation-free, and precise heat treatment for industries where performance and reliability matter most. For manufacturers in aerospace, automotive, and medical sectors, the vacuum heat treatment furnace is not just a tool—it is a necessity.

8.Frequently Asked Questions (FAQ)

Q: What is the main purpose of the vacuum furnace?

A: The main purpose of the vacuum furnace is to process metals in an oxygen-free environment, preventing oxidation and ensuring high-quality results.

Q: What is a vacuum heat treatment furnace used for?

A: A vacuum heat treatment furnace is used for hardening, tempering, annealing, brazing, and sintering metals with precision.

Q: Why do manufacturers choose the vacuum furnace over traditional furnaces?

A: Because the vacuum furnace prevents contamination, ensures cleaner surfaces, and achieves better mechanical properties.

Q: Which industries benefit most from the vacuum furnace?

A: Aerospace, automotive, medical device manufacturing, and toolmaking industries.

Q: What are the disadvantages of the vacuum furnace?

A: Higher cost, complex maintenance, and less suitability for low-value, mass-produced items.