What is the Most Efficient Type of Vacuum Furnace?

1. Introduction

The vacuum furnace is a critical piece of equipment used in heat treatment processes across various industries. These furnaces operate in a controlled vacuum environment, which helps to prevent oxidation, contamination, and scaling during the heat treatment of metals and other materials. While all vacuum furnaces are designed to offer improved performance and precision, there are variations that make some models more efficient than others. This article will explore the most efficient types of vacuum furnaces, highlighting their energy-saving benefits, processing capabilities, and application areas.

2. What Makes a Vacuum Furnace Efficient?

Efficiency in the vacuum furnace is determined by several key factors, including energy consumption, heating uniformity, and the quality of the final output. Energy-efficient furnaces use advanced insulation materials, optimized heating cycles, and energy recovery systems that reduce overall energy usage. Furthermore, vacuum furnaces with precise temperature control and multi-zone heating capabilities can provide uniform heating, which reduces energy waste and ensures the quality of the processed materials. Efficiency also refers to faster processing times, which increase throughput and reduce downtime in manufacturing environments.

3. Types of Vacuum Furnaces and Their Efficiency

There are various types of vacuum furnaces, each offering different levels of efficiency depending on the intended application. Some of the most efficient vacuum furnaces include:

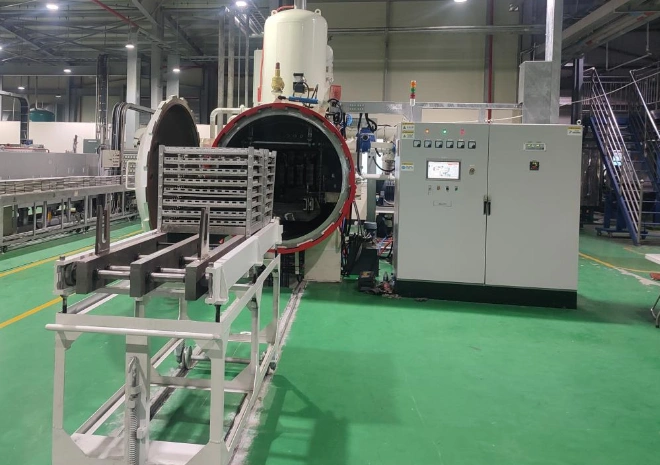

The Vacuum Heat Treatment Furnace

The vacuum heat treatment furnace is among the most efficient types of vacuum furnaces for general heat treatment processes such as hardening, annealing, and tempering. These furnaces are designed with advanced temperature control systems that allow for uniform heat distribution, reducing energy loss and improving the efficiency of the entire process. With precise control over heating and cooling cycles, the vacuum heat treatment furnace can achieve faster processing times, resulting in higher production efficiency.

The Vacuum Sintering Furnace

The vacuum sintering furnace is widely used in powder metallurgy applications, where fine powders are fused to create solid parts. These furnaces are designed to operate in a vacuum environment, which prevents oxidation and contamination. The most efficient vacuum sintering furnaces are equipped with advanced heating elements that reduce heat-up and cool-down times. By utilizing energy-efficient heating systems, these furnaces minimize energy consumption while ensuring high-quality sintered parts with minimal defects.

The Customizable Vacuum Furnace

For specific industrial needs, customizable vacuum furnaces are available. These furnaces can be tailored to optimize energy consumption based on the required temperature, pressure, and processing time. With advanced automation and energy-efficient insulation, these customizable furnaces provide a high level of precision and control, ensuring optimal performance while reducing overall energy costs.

4. Why Efficiency Matters in Vacuum Furnaces

Efficiency plays a vital role in the overall performance of the vacuum furnace, and it has several advantages for manufacturers and industries. First, energy-efficient vacuum furnaces help reduce operational costs by minimizing energy consumption. With rising energy prices and sustainability concerns, reducing energy use can lead to significant cost savings for manufacturers.

Second, efficient vacuum furnaces provide faster processing times, which help increase throughput and reduce downtime. This is especially important in high-volume production environments where meeting deadlines is crucial.

Third, efficiency also translates into improved product quality. Uniform heating and precise control allow for better consistency in the final product, reducing defects and minimizing the need for post-processing.

Lastly, energy-efficient vacuum furnaces are more environmentally friendly. By using less energy, they contribute to a smaller carbon footprint, which aligns with global efforts to reduce energy consumption and promote sustainability.

5. Conclusion

Choosing the most efficient vacuum furnace depends on the specific needs of your industry. However, the vacuum heat treatment furnace, the vacuum sintering furnace, and the customizable vacuum furnace are among the most efficient options available. These furnaces offer a combination of precise control, energy-saving features, and faster processing times, making them ideal for industries that demand high-quality results and efficient production.

6. Frequently Asked Questions (FAQ)

Q: What makes a vacuum furnace more energy-efficient?

A: A vacuum furnace becomes more energy-efficient through advanced insulation, automated temperature controls, and energy recovery systems that minimize heat loss during processing.

Q: Can a vacuum furnace be used for all types of materials?

A: Yes, vacuum furnaces are versatile and can be used for various materials, including metals, ceramics, and composites. The specific furnace type chosen depends on the material and the required heat treatment process.

Q: How does the vacuum furnace prevent oxidation?

A: The vacuum environment prevents oxidation by eliminating oxygen during the heat treatment process, ensuring that materials remain clean and uncontaminated.

Q: What is the role of energy recovery systems in vacuum furnaces?

A: Energy recovery systems capture and reuse heat from the furnace exhaust, reducing the overall energy consumption and making the furnace more efficient.

Q: How long does the vacuum furnace heat treatment process take?

A: Processing times vary depending on the material and heat treatment type. However, energy-efficient vacuum furnaces can significantly reduce processing times compared to traditional methods.