What is the Difference Between the Vacuum Furnace and an Air Furnace?

1. Introduction

The vacuum furnace and an air furnace are both used for heat treatment of materials like metals, alloys, and ceramics, but they operate under different conditions and are suited to different applications. While air furnaces are used in more traditional heat treatment processes, the vacuum furnace offers advanced capabilities that make it ideal for industries requiring precise control over material properties and high-quality results.

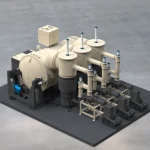

2. Understanding the Basics: What is the Vacuum Furnace?

The vacuum furnace is a specialized heat treatment system that operates in a controlled vacuum atmosphere. By removing air and creating a vacuum inside the furnace, it prevents oxidation, decarburization, and contamination of the materials being heated. The vacuum furnace is commonly used for processes like annealing, brazing, sintering, and hardening, where high-quality and clean surfaces are essential.

3. What is an Air Furnace?

An air furnace, also known as an atmospheric furnace, is a heat treatment system that operates in the presence of air. Unlike the vacuum furnace, air furnaces use gases, including oxygen, to conduct the heating process. This type of furnace is commonly used for more basic processes like annealing, tempering, and hardening of metals that do not require a contaminant-free atmosphere.

4. Key Differences Between the Vacuum Furnace and an Air Furnace

Operating Atmosphere

The vacuum furnace operates in a vacuum or controlled inert gas environment, preventing oxidation and contamination during the heating process. In contrast, the air furnace operates in the presence of atmospheric air, which can lead to oxidation, scaling, and contamination of the material’s surface.

Applications and Precision

The vacuum furnace is ideal for industries that require precise control over material properties, including aerospace, automotive, medical devices, and high-performance tooling. It is used for sintering, brazing, hardening, and annealing of delicate materials. On the other hand, the air furnace is more commonly used for less demanding applications, such as annealing and tempering of standard metals and alloys in industries like construction and general manufacturing.

Material Quality and Surface Finish

The vacuum furnace ensures high-quality surface finishes by preventing oxidation and contamination, making it suitable for high-precision components. Meanwhile, the air furnace often results in oxidation or surface scaling, which may require additional cleaning or finishing processes to achieve the desired material quality.

Energy Efficiency

The vacuum furnace is more energy-efficient for certain processes, as it requires less time for heating and cooling due to the vacuum’s insulating properties. On the other hand, the air furnace tends to be less energy-efficient, especially when dealing with processes that require higher temperatures, as air allows more heat loss during operation.

Cost and Complexity

The vacuum furnace is typically more expensive due to the complex technology and control systems required for vacuum operation. However, it offers superior results and a longer lifespan for high-performance applications. In comparison, the air furnace is less expensive and easier to maintain, making it a good option for standard applications and general manufacturing.

5. Applications of the Vacuum Furnace vs. Air Furnace

The vacuum furnace is used in various industries that require high precision and material quality. Some of its common applications include:

● Aerospace components, such as turbine blades, engine parts, and other high-strength, heat-resistant materials.

● Automotive parts, including high-performance gears, bearings, and transmission components.

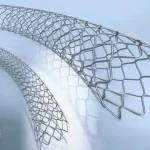

● Medical devices, including implants and surgical tools, which require biocompatibility and high performance.

● Tooling and molds, where high hardness and wear resistance are crucial.

● Electronics, where precision components like capacitors, resistors, and sensors are often sintered or hardened.

The air furnace is more commonly used for general heat treatment processes in industries such as:

● General metal hardening (steel, alloys).

● Annealing of copper, aluminum, and other metals.

● Tempering of components for industrial machinery and construction materials.

6. Advantages of the Vacuum Furnace Over an Air Furnace

The vacuum furnace offers several advantages:

● No Oxidation: The vacuum environment ensures that materials do not suffer from oxidation, improving the quality of the surface and preserving mechanical properties.

● Cleaner Surface Finish: Parts processed in the vacuum furnace do not require additional cleaning, as the absence of air prevents the formation of scales or residues.

● Precision and Control: The vacuum furnace offers better control over temperature, pressure, and cooling rates, making it ideal for high-precision applications.

7. Conclusion

While both the vacuum furnace and the air furnace serve as essential tools in heat treatment processes, they cater to different needs. The vacuum furnace is designed for high-precision applications where material integrity and surface quality are crucial, making it ideal for industries like aerospace and medical device manufacturing. On the other hand, an air furnace is more suitable for general applications where oxidation and surface contamination are less of a concern.

8. Frequently Asked Questions (FAQ)

Q: Can the vacuum furnace replace the air furnace for all applications?

A: While the vacuum furnace offers superior results for certain high-performance applications, the air furnace is still used for more basic heat treatment processes where surface quality is not as critical.

Q: Is the vacuum furnace more expensive than an air furnace?

A: Yes, the vacuum furnace is typically more expensive due to its advanced technology and the vacuum environment, but it offers higher-quality results and is necessary for precise applications.

Q: How does an air furnace affect the surface finish of metals?

A: The presence of oxygen in an air furnace can cause oxidation and scaling, which may require additional cleaning or finishing steps to achieve the desired surface quality.

Q: What industries benefit most from using the vacuum furnace?

A: Industries such as aerospace, automotive, medical devices, and tooling benefit from using the vacuum furnace due to their need for precise, high-quality components and materials.

Q: Can the vacuum furnace be used for sintering processes?

A: Yes, the vacuum furnace is often used for sintering powder materials, as the vacuum environment prevents oxidation and contamination, improving the properties of the final product.