What Is a Vacuum Brazing Furnace and How Does It Work?

1. Introduction: The Role of Vacuum Brazing in Modern Manufacturing

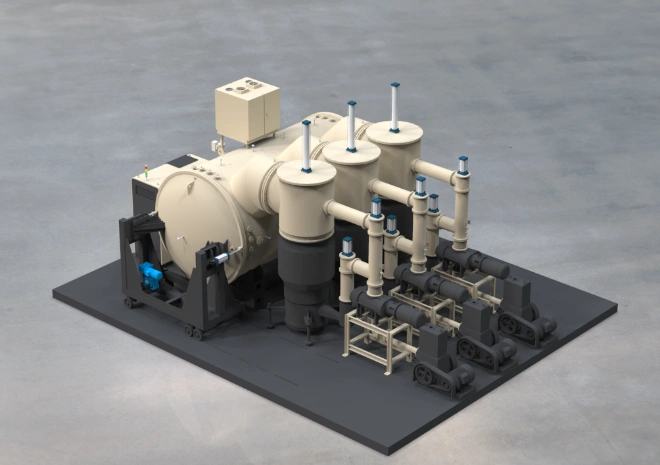

Vacuum brazing furnaces are essential for producing high-quality, clean, and precise joints in metals. They are widely used in industries where performance and reliability are critical, such as aerospace, medical technology, and electronics.

2. Understanding Vacuum Brazing Technology

What Is Vacuum Brazing?

Vacuum brazing is a joining method where a filler metal melts and flows between base metals inside a vacuum environment, creating strong, clean joints without flux or oxidation.

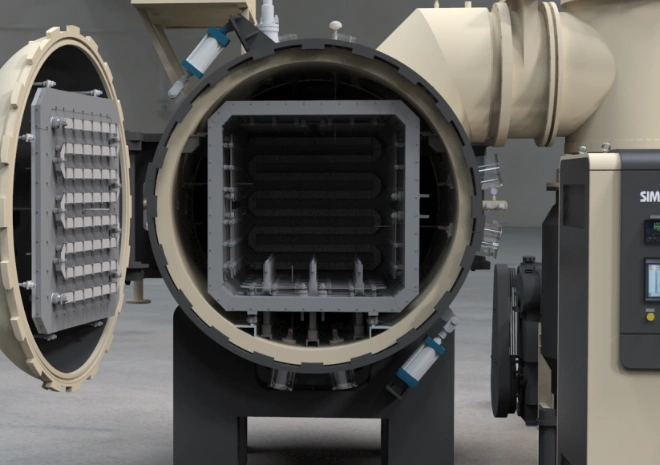

The Function of a Vacuum Furnace

The Vacuum Brazing Furnace provides a controlled atmosphere, precise heating, and uniform temperature distribution to ensure consistent brazing quality.

3. How Does a Vacuum Brazing Furnace Work?

Step 1: Loading Components

Parts to be joined are cleaned and placed inside the furnace chamber.

Step 2: Creating a Vacuum Environment

Air and gases are removed to eliminate oxidation during brazing.

Step 3: Controlled Heating Cycle

The furnace heats the parts gradually to the brazing temperature.

Step 4: Alloy Flow and Joint Formation

The filler alloy melts and spreads through capillary action, forming strong joints.

Step 5: Cooling and Quality Assurance

The furnace cools the assembly under vacuum, ensuring minimal contamination and distortion.

4. Practical Benefits of Vacuum Brazing

Clean and Oxidation-Free Joints – no flux required.

High Precision and Repeatability – essential for sensitive industries.

Compatibility with Complex Designs – suitable for intricate assemblies.

5. Why Vacuum Brazing Is Not Always Used

Higher Equipment and Process Costs – requires expensive furnaces and maintenance.

Strict Process Control Requirements – skilled operators are needed.

Limited Suitability – some metals and alloys are not ideal for vacuum brazing.

6. Comparing Vacuum Brazing with Conventional Brazing

Vacuum Brazing Advantages

Cleaner, stronger joints

No flux contamination

Better control over microstructure

Traditional Brazing Advantages

Lower cost

Simpler equipment

Faster setup for low-volume production

7. Where Vacuum Brazing Excels

Aerospace Industry – turbine blades, heat exchangers.

Medical Devices – surgical instruments, implants.

Electronics – power modules, hermetic sealing.

Automotive – engine components, EV cooling plates.

8. Advantages and Disadvantages of Vacuum Brazing

Advantages

Superior joint strength and reliability

Oxidation-free process

Precise temperature control

Suitable for complex geometries

Disadvantages

High capital investment

Limited material flexibility

Requires skilled operation

9. The Bottom Line

A Vacuum Brazing Furnace is a powerful tool for high-quality metal joining, especially where strength, precision, and cleanliness are essential. While it involves higher costs and stricter requirements, the long-term benefits make it the preferred choice for critical industries.

10.Frequently Asked Questions (FAQ)

Q: What is a Vacuum Brazing Furnace used for?

A: It is used to join metals in a clean, controlled vacuum environment, producing high-strength, oxidation-free joints.

Q: How does vacuum brazing differ from conventional brazing?

A: Vacuum brazing uses a vacuum atmosphere without flux, while conventional brazing typically requires flux and is more prone to oxidation.

Q: In which industries is vacuum brazing commonly applied?

A: Aerospace, medical devices, electronics, and automotive manufacturing.

Q: What metals can be brazed in a vacuum furnace?

A: Stainless steel, titanium, nickel-based alloys, aluminum, and copper.

Q: Why is vacuum brazing more expensive than traditional brazing?

A: The furnaces are costly, require precise controls, and need skilled operators.

Q: Does vacuum brazing improve product quality?

A: Yes, it provides stronger, cleaner, and more reliable joints compared to traditional methods.

Q: Can vacuum brazing be customized for specific applications?

A: Yes, manufacturers like SIMUWU offer custom vacuum brazing furnace solutions tailored to customer needs.