What is a High Precision Vacuum Furnace?

Introduction

High precision vacuum furnaces are essential in aerospace, automotive, and electronics industries for delivering accurate heat treatment. Discover how they work, their design process, and why they ensure unmatched performance in modern manufacturing.

What is a High Precision Vacuum Furnace?

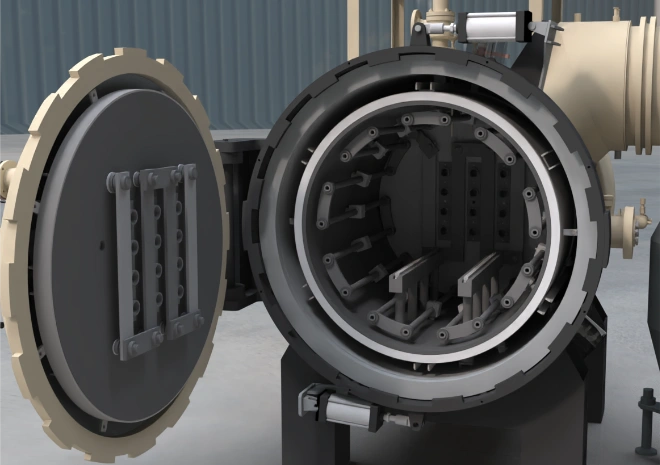

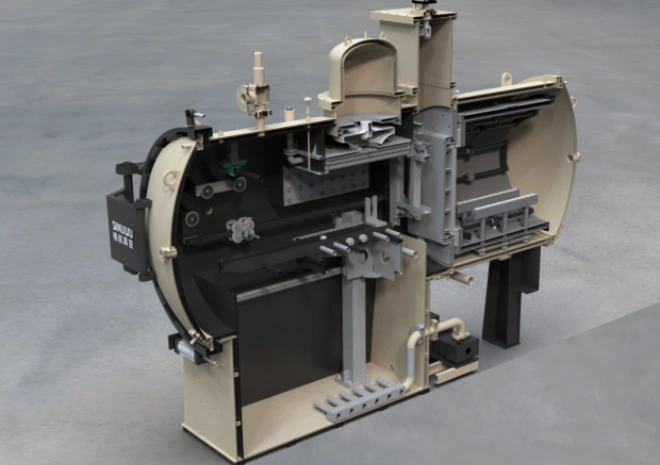

A high precision vacuum furnace is an advanced thermal processing system designed to perform controlled heating and cooling under vacuum conditions. Unlike conventional furnaces, it minimizes oxidation, contamination, and dimensional distortions, ensuring the highest quality of treated materials.

These furnaces are widely used in industries where tolerance, purity, and microstructure consistency are critical, such as aerospace, defense, semiconductors, and medical equipment.

Why Precision Matters in Heat Treatment

In heat treatment, even a small deviation in temperature or atmosphere can lead to defects like cracks, reduced hardness, or poor fatigue resistance. Precision vacuum furnaces eliminate these risks by:

Maintaining exact temperature control (±1°C or better).

Ensuring uniform heat distribution across components.

Creating oxygen-free environments for clean and bright results.

Thus, precision is not just a technical advantage—it directly impacts product reliability, safety, and lifecycle costs.

The Engineering Design Process of Vacuum Furnaces

Just like the engineering design process in product development, creating a high precision vacuum furnace involves systematic steps to guarantee efficiency, safety, and long-term performance.

This process is iterative and requires engineers to revisit earlier stages whenever new data or performance challenges emerge.

Key Steps in Developing High Precision Vacuum Furnaces

1. Define the Requirements

Engineers begin by clarifying the target application: aerospace turbine blades, precision molds, or electronic components. Key requirements include:

Temperature ranges (e.g., up to 1300°C).

Vacuum levels (10⁻³–10⁻⁶ mbar).

Cooling speed and uniformity.

2. Research and Data Gathering

This involves studying existing furnace designs, materials, and insulation technologies. Research also considers:

Energy efficiency

Material compatibility

Industry-specific standards (AMS, NADCAP, ISO)

3. Brainstorming Solutions

Teams explore innovative ideas like:

Multi-zone heating elements for uniformity.

Advanced thermal shields for reduced energy loss.

Computer-aided process control for precision monitoring.

4. Prototyping and Simulation

Before building, engineers use CAD models and thermal simulations to predict furnace behavior. Virtual testing helps refine designs and reduces costly physical trials.

5. Testing and Evaluation

Prototypes are manufactured and undergo rigorous tests:

Leak tightness for vacuum integrity.

Temperature calibration accuracy.

Stress testing under maximum loads.

6. Implementation

Once approved, the furnace enters commercial production and industrial deployment, customized for client requirements.

7. Monitoring and Optimization

Even after delivery, engineers monitor furnace performance, upgrading software or hardware to enhance precision and extend lifespan.

Applications Across Industries

Aerospace

Heat treatment of turbine blades, gears, and landing gear components where reliability under extreme conditions is non-negotiable.

Automotive

Hardening of transmission gears, precision tooling, and electric vehicle components.

Electronics & Semiconductors

Annealing and brazing of sensitive components requiring ultra-clean surfaces.

Medical Devices

Sterile and precise processing of surgical tools and implants.

Challenges in Designing High Precision Vacuum Furnaces

While advanced, the development of these furnaces faces several constraints:

Cost Pressure: High-precision systems require advanced materials and controls, raising initial investment.

Energy Efficiency: Balancing high temperature performance with sustainable power use.

Material Limitations: Not all alloys can withstand repeated vacuum cycling.

Regulatory Standards: Meeting aerospace and medical industry certifications adds complexity.

The Future of Precision Heat Treatment

The next generation of high precision vacuum furnaces will integrate:

AI-driven process control for real-time optimization.

IoT connectivity for predictive maintenance.

Eco-friendly designs reducing power consumption and carbon footprint.

Modular configurations to meet flexible industrial needs.

Frequently Asked Questions

Q: What is the advantage of a high precision vacuum furnace over a traditional furnace?

A: It provides superior accuracy, cleaner processing, and improved mechanical properties of materials.

Q: What industries rely most on vacuum heat treatment?

A: Aerospace, automotive, medical devices, and semiconductor manufacturing.

Q: How does vacuum level affect heat treatment results?

A: Higher vacuum levels reduce oxidation and contamination, ensuring brighter and stronger finished parts.

Q: Are high precision vacuum furnaces energy-efficient?A: Yes. Modern designs integrate insulation and advanced heating controls to optimize energy use.

The Bottom Line

The high precision vacuum furnace represents the pinnacle of engineering in heat treatment technology. By following a structured engineering design process, manufacturers ensure furnaces deliver unmatched accuracy, reliability, and efficiency.

From aerospace components to medical implants, these systems are central to modern industry’s demand for precision and performance. As technology evolves, their role will only grow—shaping the future of advanced manufacturing.