Vacuum furnaces rely on integrated systems for precision heat treatment. This guide explores core components—from chambers to PLC controls—ensuring superior performance and reliability.

Table of Contents

- 1. Overview of Vacuum Furnaces

- 2. Function of Core Components

- 3. How Components Interact

- 4. Importance of Quality Parts

- 5. Troubleshooting

- 6. Summary

- 7. FAQ

1. Overview of Vacuum Furnaces

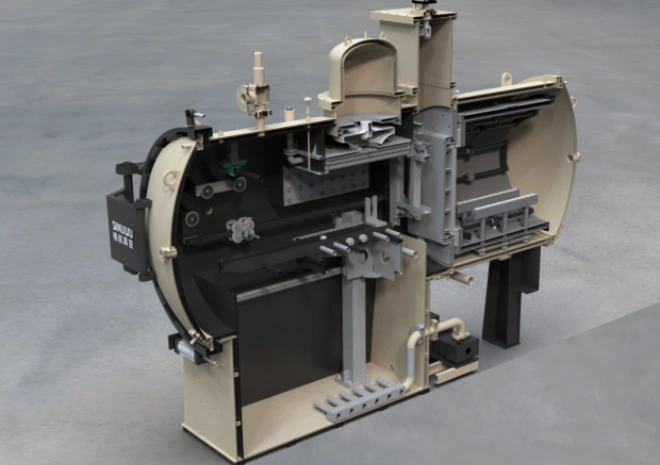

Vacuum furnaces are specialized equipment designed to create a controlled, low-pressure environment for heat treatment processes such as annealing, brazing, and sintering.

These furnaces are critical in industries like aerospace, automotive, and metalworking, where precise control over temperature and atmosphere is essential for achieving desired material properties.

Understanding the core components of vacuum furnaces is vital for their proper operation, maintenance, and optimization.

2. Understanding the Function of Each Core Component

2.1 Furnace Chamber: The Heart of Heat Treatment

● Design and Material Selection

The furnace chamber is the enclosed space where the heat treatment process occurs. It is typically constructed from high-temperature-resistant alloys such as stainless steel or carbon steel. These materials ensure the chamber can withstand extreme temperatures and vacuum conditions without compromising structural integrity.

● Size and Shape Considerations

The size and shape of the chamber are crucial for accommodating different workpiece sizes and achieving uniform heat distribution. A well-designed chamber minimizes temperature gradients, ensuring consistent heat treatment results across the entire workpiece.

2.2 Vacuum System: Creating the Low-Pressure Environment

2.2.1 Vacuum Pumps: The Workhorses

● Types of Vacuum Pumps

Vacuum furnaces utilize various types of vacuum pumps, including rotary vane pumps, diffusion pumps, and cryogenic pumps. Each type plays a specific role in evacuating air and other gases from the furnace chamber.

Rotary Vane Pumps: Ideal for achieving low to medium vacuum levels, these pumps are commonly used for initial evacuation.

Diffusion Pumps: Capable of reaching high vacuum levels, diffusion pumps are used for fine-tuning the vacuum environment.

Cryogenic Pumps: These pumps use cryogenic temperatures to condense and trap gases, achieving ultra-high vacuum levels.

When selecting vacuum pumps, factors such as pumping speed, ultimate vacuum level, and reliability must be considered. The choice of pump depends on the specific requirements of the heat treatment process.

2.2.2 Valves and Piping: Controlling the Flow

● Role of Valves

Valves regulate the flow of gases in and out of the furnace chamber. They play a critical role in maintaining the desired vacuum level and controlling the introduction of process gases.

● Types of Valves

Gate Valves: Used for isolating sections of the vacuum system, gate valves provide a tight seal when closed.

Butterfly Valves: These valves are suitable for controlling gas flow rates and are often used in processes requiring precise atmosphere control.

Needle Valves: Ideal for fine-tuning gas flow, needle valves offer high precision and are commonly used in applications requiring exact gas mixtures.

● Importance of Piping Design

Proper piping design ensures efficient gas flow and minimizes leaks. The layout of the piping system must consider factors such as pipe diameter, length, and the number of bends to optimize performance.

2.3 Heating System: Providing the Necessary Energy

2.3.1 Heating Elements: Generating Heat

● Types of Heating Elements

Common heating elements used in vacuum furnaces include resistance heating elements (e.g., molybdenum disilicide, graphite) and induction heating coils.

Resistance Heating Elements: These elements generate heat through electrical resistance. Molybdenum disilicide offers high-temperature stability, while graphite provides excellent thermal conductivity.

Induction Heating Coils: Induction coils use electromagnetic fields to induce eddy currents in the workpiece, generating heat. This method is highly efficient and allows for rapid heating.

● Advantages and Disadvantages

Each type of heating element has its advantages and disadvantages. Resistance heating elements are straightforward and cost-effective but may suffer from uneven temperature distribution. Induction heating coils offer precise temperature control and rapid heating but require more complex control systems.

● Factors Affecting Lifespan

The lifespan of heating elements is influenced by factors such as operating temperature, oxidation, and thermal cycling. Regular maintenance and proper operation can extend the life of these components.

2.3.2 Temperature Control Devices: Ensuring Precision

● Importance of Accurate Temperature Control

Precise temperature control is crucial for achieving desired material properties. Incorrect temperatures can lead to defects, weakening the material or altering its structure.

● Types of Temperature Control Devices

Thermocouples: These devices measure temperature by generating a voltage proportional to the temperature difference between two junctions.

Infrared Pyrometers: Infrared pyrometers measure temperature by detecting the infrared radiation emitted by the workpiece.

Optical Pyrometers: Optical pyrometers use the visible spectrum to measure temperature, offering high accuracy in specific applications.

● Working in Conjunction with the Control System

These temperature control devices work with the control system to maintain the set temperature within a tight tolerance. The control system adjusts the heating power based on feedback from the temperature sensors.

2.4 Cooling System: Managing the Temperature Drop

2.4.1 Cooling Medium Selection

● Types of Cooling Media

Common cooling media used in vacuum furnaces include gas quenching (e.g., nitrogen, helium) and oil quenching.

Gas Quenching: Offers rapid cooling rates and is suitable for materials that require minimal distortion. Nitrogen is commonly used for its cost-effectiveness, while helium provides faster cooling rates.

Oil Quenching: Provides slower cooling rates and is ideal for materials that are prone to cracking. Oil quenching also offers better distortion control.

● Advantages and Disadvantages

Each cooling medium has its advantages and disadvantages. Gas quenching is environmentally friendly but may not provide sufficient cooling for some materials. Oil quenching offers excellent cooling performance but requires proper disposal of used oil.

● Factors for Selection

The choice of cooling medium depends on factors such as the type of material being processed and the desired mechanical properties. The cooling rate must be tailored to the specific requirements of the heat treatment process.

2.4.2 Cooling Circuit Design

●Components of the Cooling Circuit

The cooling circuit consists of heat exchangers, pumps, and nozzles. These components work together to ensure efficient heat transfer from the workpiece to the cooling medium.

Heat Exchangers: Transfer heat from the cooling medium to the surrounding environment.

Pumps: Circulate the cooling medium through the system.

Nozzles: Direct the flow of the cooling medium onto the workpiece.

● Importance of Maintenance

Proper maintenanceof the cooling circuit is essential to prevent clogging and ensure consistent cooling performance. Regular inspection and cleaning of the components can extend the life of the cooling system.

2.5 Control System: The Brain of the Furnace

2.5.1 Programmable Logic Controller (PLC)

● Role of the PLC

The PLC controls the various components of the vacuum furnace, including the vacuum system, heating system, and cooling system. It can be programmed to execute complex heat treatment cycles, such as temperature ramps, holds, and quenching operations.

● Advantages of Using a PLC

High Reliability: PLCs are designed for industrial environments and offer high reliability.

Flexibility: PLCs can be easily reprogrammed to accommodate different heat treatment processes.

Ease of Programming: Modern PLCs feature user-friendly programming interfaces, making them accessible to operators.

2.5.2 Human-Machine Interface (HMI)

● Features of the HMI

The HMI provides a user-friendly interface for operators to monitor and control the vacuum furnace. Key features include real-time temperature and pressure displays, alarm notifications, and data logging capabilities.

● Importance of a Well-Designed HMI

A well-designed HMI improves operator efficiency and reduces the risk of errors. Intuitive controls and clear visual feedback enable operators to manage the furnace effectively.

3. How Core Components Interact to Achieve Desired Results

The core components of a vacuum furnace work together in a coordinated manner to achieve the desired heat treatment results. The vacuum system creates a low-pressure environment, preventing oxidation and contamination. The heating system raises the temperature of the workpiece to the required level, while the temperature control devices ensure precise temperature regulation. The cooling system manages the rate of cooling, achieving specific material properties. The control system, via the PLC and HMI, orchestrates the entire process, ensuring the furnace operates as programmed.

4. Importance of High-Quality Core Components

Using high-quality core components is essential for ensuring reliable operation, long service life, and consistent heat treatment results. Low-quality components can lead to frequent breakdowns, reduced productivity, and poor product quality. Investing in high-quality components minimizes downtime and ensures optimal performance.

5. Common Issues and Troubleshooting of Core Components

5.1 Vacuum Leaks

● Symptoms

Inability to reach the required vacuum level.

Unusual noises from the vacuum pumps.

● Troubleshooting Tips

Inspect the chamber and piping for cracks or leaks.

Check the vacuum seals and gaskets for wear and replace if necessary.

Ensure all valves are properly closed and functioning.

5.2 Heating Element Failures

● Symptoms

Inconsistent temperature readings.

Reduced heating efficiency.

● Troubleshooting Tips

Inspect the heating elements for signs of damage or wear.

Check the electrical connections for loose or corroded contacts.

Replace any faulty heating elements promptly.

5.3 Temperature Control Problems

● Symptoms

Temperature fluctuations during the heat treatment process.

Inability to maintain the set temperature.

● Troubleshooting Tips

Calibrate the temperature sensors and control devices.

Check the control system for programming errors.

Ensure proper ventilation and cooling of the control cabinet.

6. Summary

Understanding the core components of a vacuum furnace is essential for successful operation and maintenance. Each component plays a critical role in achieving the desired heat treatment results. High-quality components and proper troubleshooting are vital for ensuring optimal performance and product quality. By investing in reliable components and following best practices for maintenance, operators can maximize the efficiency and lifespan of their vacuum furnaces.

7. Frequently Asked Questions (FAQ)

Q: What is the most critical core component of a vacuum furnace?

A: All core components are vital, but the furnace chamber is often most critical as it houses the workpiece and withstands extreme conditions during heat treatment.

Q: How does the vacuum system affect the performance of a vacuum furnace?

A: A good vacuum system removes air and gases, creating a clean environment. This prevents oxidation and contamination, ensuring high-quality heat treatment results.

Q: What are the different types of heating elements used in vacuum furnaces?

A: Common types include resistance heating elements like molybdenum disilicide and graphite, and induction heating coils. Each has unique heating characteristics.

Q: Why is temperature control so important in a vacuum furnace?

A: Precise temperature control ensures the workpiece reaches the desired properties. Incorrect temperatures can lead to defects, weakening the material or altering its structure.

Q: How often should the core components of a vacuum furnace be maintained?

A: Maintenance frequency depends on usage. Generally, regular checks and more in-depth maintenance are recommended to prevent breakdowns.

Q: Can I replace a core component of a vacuum furnace with a non-standard part?

A: It’s not advisable. Non-standard parts may not fit properly, affect performance, and could even cause safety hazards due to incompatible materials or designs.

Q: What are the signs of a failing vacuum pump in a vacuum furnace?

A: Signs include reduced pumping speed, unusual noises, and inability to reach the required vacuum level. These indicate the pump needs repair or replacement.

Q: How does the cooling system impact the quality of heat treatment in a vacuum furnace?

A: The cooling rate affects the material’s microstructure. A proper cooling system ensures consistent cooling, preventing cracks and achieving the desired mechanical properties.

Q: What role does the control system play in the operation of a vacuum furnace?

A: The control system, via PLC and HMI, manages all components. It sets and monitors temperatures, vacuums, and cooling, ensuring the furnace runs as programmed.

For more insights, feel free to explore our related articles or contact us for professional consultation.