1.Introduction to Vacuum Sintering

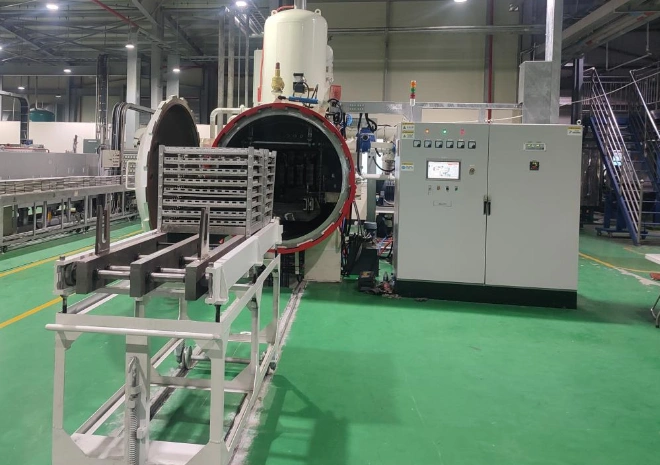

Vacuum sintering is a high-precision thermal process carried out inside the vacuum furnace, where metal or ceramic powders are heated below their melting points. Through atomic diffusion, powders bond into dense and durable structures. Compared with traditional sintering, vacuum furnace sintering offers cleaner surfaces, superior mechanical properties, and higher energy efficiency, making it widely adopted in aerospace, medical, electronics, and automotive industries.

2.Core Advantages of Vacuum Sintering

Elimination of Surface Oxidation and Decarburization

In atmospheric sintering, oxygen causes oxidation and decarburization, weakening material performance. By contrast, vacuum sintering in the vacuum furnace prevents oxygen interaction, ensuring bright, oxide-free surfaces and homogeneous microstructures. For example, titanium alloys treated with vacuum furnace sintering achieve up to 30% higher fatigue resistance.

Enhanced Environmental Sustainability

Since the vacuum furnace removes the need for harmful gases, vacuum sintering produces no toxic emissions and requires no extra gas treatment. It aligns with global sustainability goals, cutting energy consumption by 40–50% compared with conventional sintering.

Precision Temperature Control

Modern vacuum furnaces use multi-zone heating and advanced monitoring systems. This allows vacuum furnace sintering to maintain a temperature accuracy of ±5°C, far superior to ±10°C in atmospheric sintering. The result is reduced residual stress and better structural consistency in components.

High Mechanical Integration

Vacuum sintering enables complex designs, such as lightweight lattice structures used in aerospace. The dense and uniform bonding achieved inside the vacuum furnace improves tensile strength, hardness, and wear resistance, especially in high-performance alloys.

Significant Energy Efficiency

Thanks to advanced insulation and optimized heating, vacuum furnace sintering consumes up to 50% less energy than traditional furnaces. A 100 kg stainless steel batch requires about 120 kWh in a vacuum furnace compared with 240 kWh in conventional equipment.

3.Applications of Vacuum Sintering

Aerospace: Turbine disks, heat shields, superalloys

Medical: Orthopedic implants, dental prosthetics

Electronics: Ceramic substrates, semiconductor packaging

Automotive: EV battery components, transmission gears

4.Comparison with Traditional Sintering Methods

| Parameter | Vacuum Furnace Sintering | Conventional Sintering |

|---|---|---|

| Surface Quality | Oxide-free, no decarburization | Prone to oxidation |

| Energy Efficiency | 40–60% lower energy use | Higher costs |

| Temperature Control | ±5°C uniformity | ±10°C variability |

| Material Flexibility | Suitable for reactive metals (Ti, Zr) | Limited to stable alloys |

5.Future Trends in Vacuum Furnace Sintering

Hybrid Manufacturing – Integration with additive manufacturing for near-net-shape components.

AI-driven Process Control – Machine learning enhances temperature and cycle optimization.

Sustainable Materials – Expanded use of recycled alloys and biodegradable ceramics.

6.Frequently Asked Questions (FAQ)

Q1: What is the main advantage of vacuum sintering?

A: The primary advantage of vacuum furnace sintering is the elimination of oxidation and improved energy efficiency by 40–60%.

Q2: Why do manufacturers use vacuum furnaces for sintering?

A: Because vacuum sintering produces oxide-free, denser, and stronger components compared to traditional sintering.

Q3: Which industries benefit most from vacuum sintering?

A: Aerospace, medical, electronics, and automotive sectors.

Q4: How does vacuum sintering support sustainability?

A: It eliminates harmful emissions and reduces energy consumption by up to 50%.

Q5: Is vacuum furnace sintering more expensive?

A: While equipment costs are higher, savings in energy, reduced scrap, and improved quality offset the investment.