The vacuum sintering dewaxing process for tungsten carbide (WC) cemented carbide is a core step in the process. It involves heating a compact containing forming agents such as paraffin/PEG in stages within a vacuum furnace to safely remove the forming agents and complete the densification sintering. This process directly determines the density, strength, and surface quality of the product.

1. Core Process Principles

Dewaxing: Under vacuum and heating, forming agents such as paraffin/PEG melt and vaporize, and are continuously extracted by a vacuum pump, preventing the compact from cracking due to excessive internal vapor pressure.

Vacuum Sintering: After dewaxing, the temperature continues to rise to approximately 1500℃. The cobalt (Co) binder phase forms a liquid phase, achieving WC particle rearrangement, dissolution, precipitation, and densification. The vacuum environment prevents oxidation, reduces impurities, and improves purity.

2. Main Process Steps

2.1 Furnace Loading and Preparation

Load the compact into the furnace, leaving sufficient clearance to ensure uniform airflow/heat; seal the furnace door and start the vacuum system.

Preheat the vacuum pump unit and condenser to prevent wax vapor from contaminating the pump oil.

2.2 Low-Temperature Preheating and Pre-Dewaxing:

Slowly increase the temperature to allow adsorbed water and low-boiling-point additives to evaporate, avoiding rapid expansion. Control the vacuum level within a certain range and slowly evacuate to prevent deformation of the billet.

2.3 Main Dewaxing Stage:

Temperature Plateau:

280–320℃: Paraffin wax melts in large quantities and begins to vaporize; hold for 30–60 min.

370–420℃: Main dewaxing temperature zone; hold for 60–120 min to ensure complete vaporization and removal of deep wax layers.

Heating Rate: 1–3℃/min; rapid heating is strictly prohibited to prevent sudden increases in internal vapor pressure that could cause cracking.

Vacuum Level: Dynamically controlled at 10–100 Pa, matching the dewaxing rate to ensure both evacuation and prevent billet collapse.

When the vacuum level rapidly recovers and the pressure gauge stabilizes, it indicates that the wax has been largely removed.

2.4 Pre-firing and Purification

Heating is increased at 5–10℃/min, and the vacuum level is raised to 1–10 Pa.

Residual trace amounts of wax, oxides, and impurities are removed, and the billet gains initial strength.

2.5 Vacuum Sintering and Densification

Heating rate: 10–20℃/min, achieving high vacuum.

Holding: Heating at approximately 1500℃ for 60–90 min, allowing the Co liquid phase to fully wet the WC, achieving densification.

2.6 Cooling Stage

Slowly cooled in the furnace to 1000℃, then rapidly cooled to below 200℃ before unloading, avoiding thermal stress cracking.

3. Process Advantages

- Oxidation-free: The vacuum environment prevents the oxidation of WC and Co, ensuring alloy purity and hardness.

- Thorough dewaxing: Vacuum extraction + high-temperature vaporization, residual wax <0.01%.

- High density: Reaching a theoretical density of 98–99.5%, with excellent strength and wear resistance.

- Environmentally Friendly: Wax vapor condensation and recovery, zero waste gas emissions.

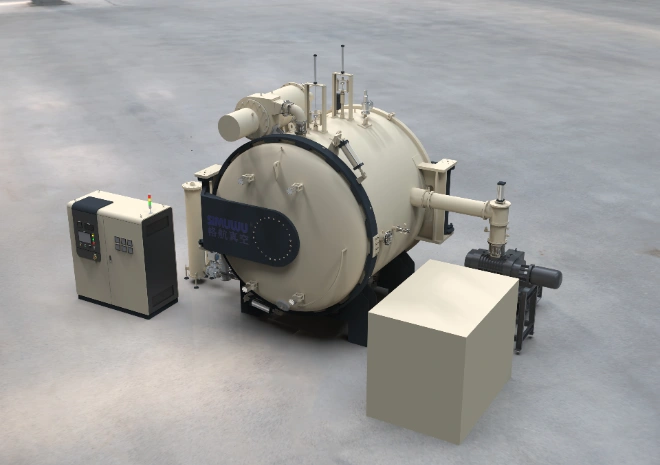

4. Why choose SIMUWU

SIMUWU’s engineering and technical personnel have developed and absorbed domestic and international temperature measurement, control, intelligent, new material, and furnace design technologies to launch a high-performance intelligent furnace particularly suitable for the cemented carbide industry (and applicable to other industries where processes permit). The equipment is mainly suitable for the sintering of tungsten carbide products and cemented carbide parts.

This equipment adopts a digital intelligent fully automatic control system, featuring excellent intelligent fully automatic control performance, powerful information processing capabilities, and network support. It helps customers complete functions including production process management, customer information management, massive storage space, historical data curve query, printing, intelligent fault analysis and alarm, and real-time dynamic equipment operation status display. It also supports remote monitoring and networked information management. The control system uses a PLC to control actions and an intelligent temperature controller to control temperature. Various advanced instruments interlock, ensuring accurate control and a high degree of automation. It can achieve seamless switching between fully automatic and manual operation, remote wireless operation, and is simple and reliable to operate.

SIMUWU specializes in the manufacture of vacuum furnaces, possessing over ten years of relevant experience and enjoying a good reputation in the vacuum furnace manufacturing field. Our product line includes vacuum gas quenching furnaces, vacuum oil quenching furnaces, vacuum brazing furnaces, and vacuum sintering furnaces, which are widely sold to developed and developing countries. Detailed technical information can be found at our official website:

Vacuum Dewaxing & Sintering Furnace

If you would like to learn more about vacuum furnace equipment, please send your requirements to kevin.liu@vacfurnace.com, and we will provide you with a satisfactory solution.