Vacuum Quenching Furnace Operation and Maintenance Guide

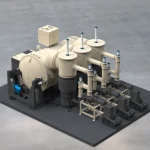

1. Introduction to Vacuum Quenching Furnace

Vacuum quenching furnaces are specialized heat treatment equipment that combines vacuum environments with controlled gas cooling. These furnaces prevent oxidation during processing and achieve precise material properties, making them essential for aerospace, automotive, and tool manufacturing industries.

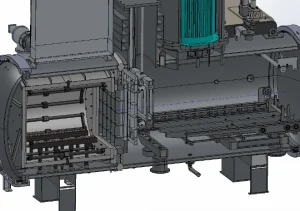

2. Core Components and Working Principle

Key Components

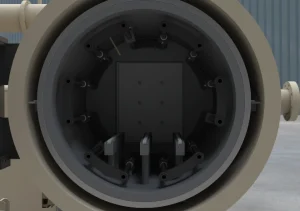

●Double-layer vacuum chamber (water-cooled structure)

●Heating system (electrical resistance or induction elements)

●Gas quenching module (nitrogen/helium at 10-20 bar pressure)

●Vacuum pump system (rotary vane + roots pumps)

●PLC temperature controller (±1℃ accuracy)

Operational Process

1.Vacuum Phase: Chamber pressure reduced to 10⁻²-10⁻⁴ Pa to eliminate oxidation

2.Heating Phase: Precise temperature control (e.g., 850℃ for tool steels)

3.Quenching Phase: High-pressure gas cooling (3-8 minutes)

4.Venting Phase: Safe chamber pressurization after cooling

3. Operation Procedures

Preparation

●Inspect chamber seals and gas connections

●Load workpieces using designated fixtures

●Initiate vacuum pumping (target ≤10⁻³ Pa)

Heating Control

●Set multi-zone temperature programs

●Monitor heating rate (≤15℃/min recommended)

●Verify uniformity via thermal couples

Quenching Execution

●Activate gas cooling at target temperature

●Adjust pressure based on material (10-20 bar)

●Maintain gas flow for specified duration

Post-Treatment

●Vent chamber below 150℃

●Remove workpieces with non-magnetic tools

●Record process parameters

4. Maintenance Requirements

Daily Checks

●Vacuum gauge verification (10⁻¹-10⁻⁴ Pa range)

●Cooling water flow inspection (≥3 L/min)

●Chamber cleaning with alcohol wipes

Weekly Tasks

●Vacuum pump oil replacement (when turbidity >NTU 5)

●Temperature sensor calibration

●Door seal lubrication

Monthly Overhaul

●Heating element resistance testing (>5% deviation replacement)

●Gas nozzle flow uniformity verification

●Safety valve pressure setting check

5. Safety Protocols

Operational Safety

●Never open chamber above 100℃

●Use heat-resistant protective gear

●Maintain clear zone around exhausts

Emergency Response

●Power failure: Activate emergency cooling

●Vacuum loss: Initiate nitrogen backfill

●Gas leak: Shut off supply and evacuate

6. Troubleshooting Guide

| Issue | Solution |

|---|---|

| Slow vacuum pumping | Replace O-ring seals |

| Uneven heating | Repair zone controller |

| Low quenching efficiency | Clean gas nozzles |

| PLC error E-03 | Recalibrate temperature sensors |

7. Performance Optimization

1.Material-Specific Settings:

●Titanium alloys: Helium quenching (≥15 bar) for H9 hardness

●Thin-walled parts: ≤10℃/min heating rate to minimize distortion

2.Process Monitoring:

●Log 50+ parameters for continuous improvement

●Combine with vacuum carburizing for ±0.01mm case depth precision

8. Summary

Vacuum quenching furnaces deliver superior material properties through oxidation-free processing and precise cooling control. Proper operation and maintenance can extend equipment lifespan by 30-50% compared to neglectful practices.

9. Frequently Asked Questions (FAQ)

Q: What materials benefit most from vacuum quenching?

A: High-alloy steels (HSS, H13), titanium alloys, and nickel-based superalloys.

Q: How does gas pressure affect cooling results?

A: 15-20 bar pressure increases cooling rate by 40% compared to 10 bar, reducing distortion.

Q: What maintenance is most critical?

A: Heating element inspection every 200 cycles and vacuum pump oil replacement every 500 hours.

Q: Can this replace traditional oil quenching?

A: Yes, for applications requiring cleaner surfaces (<0.5μm oxidation) and tighter tolerances (±0.05% distortion).

Q: What certifications do operators need?

A: Certified Vacuum Furnace Operator (CVFO) training in pressure vessel handling is recommended.