1. Introduction

D2 tool steel (Cr12Mo1V1) is a high-carbon, high-chromium cold work tool steel known for its exceptional wear resistance and high hardness. It’s also called a “semi-stainless steel” because it contains about 12% chromium, which gives it some corrosion resistance. Vacuum gas quenching is the ideal heat treatment method for D2 tool steel because it can achieve optimal overall performance while effectively avoiding deformation and cracking, all without sacrificing surface quality and dimensional accuracy.

2. Typical Parameters

The vacuum gas quenching process for D2 tool steel is a complex heat treatment procedure that requires precise control. It can usually be divided into the following key stages:

Stage 1: Preheating

First, the furnace temperature is slowly raised to 600-850°C.

Stage 2: Austenitizing

After reaching the preheating temperature, the furnace continues to heat up quickly to the austenitizing temperature, which is typically 1000-1040°C.

Stage 3: Heat Preservation

At the austenitizing temperature, the workpiece needs to be held for a period of time to ensure that the temperature is uniform throughout the part, inside and out, and that the carbides are fully dissolved. This time depends on the size and shape of the workpiece.

Stage 4: Vacuum Cooling

Once the austenitizing soaking is complete, the furnace quickly evacuates the gas from the heating chamber to achieve a high vacuum state.

Stage 5: High-Pressure Gas Quenching

Immediately after, a cooling gas (usually high-pressure nitrogen) is sprayed into the furnace chamber at a high flow rate and pressure (typically 6-10 bar). The powerful airflow creates uniform cooling on the surface of the workpiece, removing heat and achieving rapid cooling.

Stage 6: Controlled Cooling Rate

The cooling rate is critical for successful quenching. A rate that is too slow can lead to insufficient hardness, while a rate that is too fast may cause cracking. D2 steel is an air-hardening steel, so its cooling rate requirements are not as strict as those for oil-hardening steel. However, high-pressure gas quenching ensures uniform cooling and that the required hardness is achieved.

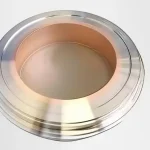

3. SIMUWU Vacuum Gas Quenching Furnace Configuration

The specific parameters of a vacuum gas quenching furnace used for D2 tool steel are as follows:

| Furnace Type | Horizontal type,single chamber, internal recycle |

| Loading Method | Front Loading |

| Effective Working Zone | 600×600×900(W×H×L mm) |

| Max. Loading Capacity | 500kg(including jig) |

| Power Supply | 3 Phase 380V(±5% );50Hz |

| Total Power | 210kw |

| Heating Power | 160kw |

| Cooling Fan Motor Power | 200kw |

| Max. Design Temperature | 1350℃ |

| Max. Working Temperature | 1250℃ |

| Working Vacuum | 6.7×10-2pa |

4. Why Choose SIMUWU as Your Vacuum Furnace Supplier

With over a decade of professional experience in the field of vacuum heat treatment furnaces, SIMUWU has an independent team of technical experts dedicated to providing reliable technical support and assurance for our customers’ specific needs.

We have established an excellent reputation in the industry for our exquisite technology and high-quality service. Our product line, which includes vacuum gas quenching furnaces, vacuum annealing furnaces, vacuum tempering furnaces, vacuum sintering furnaces, and vacuum brazing furnaces, is trusted and highly regarded by users worldwide.

Welcome to visit our website for other vacuum furnace products

You can also contact us directly via email for inquiries: kevin.liu@vacfurnace.com