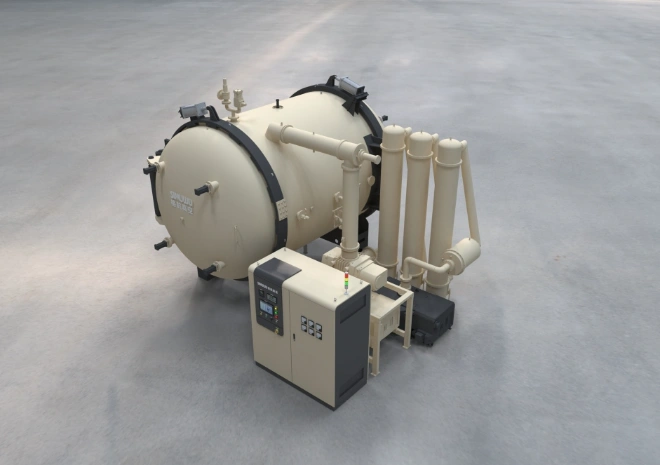

Cemented carbide plays a crucial role in many industrial applications. To ensure excellent hardness, wear resistance, toughness, and density, the dewaxing and sintering processes must be precisely controlled. A dewaxing-sintering vacuum furnace can complete both key process steps—dewaxing and sintering—within a single furnace, significantly improving production efficiency and product quality.

Working Principle

1. Dewaxing Stage

In the production of cemented carbide, a binder (usually wax) is used to help shape the powder. The purpose of the dewaxing stage is to remove this binder to ensure the density and mechanical properties of the cemented carbide during sintering.

The integrated dewaxing-sintering vacuum furnace gradually increases the temperature to 200°C to 600°C under low vacuum conditions, causing the wax to evaporate in a vacuum or inert gas environment, avoiding the release of harmful gases and oxidation reactions.

2. Pre-sintering Stage

After dewaxing, the green cemented carbide blank becomes more brittle. To enhance stability, the temperature during the pre-sintering stage is controlled between 600°C and 900°C, ensuring stable billet shape and a certain degree of toughness.

3. Sintering Stage

Sintering is a crucial step in cemented carbide manufacturing, typically conducted at temperatures ranging from 1350°C to 1500°C in a vacuum or inert atmosphere. This process melts the cobalt-based metal at high temperatures, allowing it to combine with carbide particles to form a high-density, high-hardness cemented carbide.

Equipment Features

1. Precise Temperature Control

The integrated dewaxing-sintering vacuum furnace is equipped with a precise temperature control system, ensuring uniform temperature distribution within the furnace, with an error range controlled between ±3°C and ±5°C. This is crucial for ensuring consistent quality across batches of cemented carbide products, avoiding performance fluctuations caused by temperature differences.

2. High Vacuum and Atmosphere Control

The vacuum level within the furnace can reach ≤5×10⁻³ Pa, providing an ideal oxidation-free environment for the sintering process. High vacuum not only prevents oxidation but also avoids surface contamination, ensuring the corrosion resistance and oxidation resistance of cemented carbide.

3. High-Efficiency Dewaxing: The high-efficiency exhaust system in the dewaxing process effectively removes wax vapor and waste gas, preventing secondary pollution. The system’s efficiency keeps the furnace environment clean at all times, extending equipment lifespan and ensuring no contamination during sintering.

4. Pressure Sintering: For applications requiring higher density and stronger performance, the equipment also supports pressure sintering. By applying additional gas pressure, the density of the cemented carbide can be further improved, enhancing the material’s compressive strength and wear resistance, making it suitable for applications with more demanding performance requirements.

5. Automated Control: The furnace is equipped with a PLC automatic control system that automatically adjusts temperature and vacuum according to the set process curve, ensuring accuracy at every stage of production. Operation is simple, requiring no manual intervention, reducing labor costs and improving production efficiency.

Application Areas

Integrated dewaxing-sintering vacuum furnaces are widely used in the production of cemented carbide, suitable for the following fields:

1. Tool Manufacturing

Cemented carbide tools such as end mills, drills, and cutting tools require extremely high hardness and wear resistance to ensure their stability and service life during high-speed cutting. Integrated dewaxing-sintering vacuum furnaces, through precise temperature control and vacuum sintering, ensure the hardness, sharpness, and wear resistance of the tools.

2. Engineering Machinery

Cemented carbide is widely used in engineering tools such as drills and cutting teeth. Pressure sintering significantly improves the impact resistance and wear resistance of these tools, extending their service life and increasing work efficiency.

3. High-Precision Molds

The application of cemented carbide in the field of precision molds is also very important, such as punches and wire drawing dies. Through a precise sintering process, high density and excellent mechanical properties of the molds can be ensured, thereby meeting the requirements of high-precision machining.

4. Custom Carbide Parts

For special-purpose or custom carbide parts, an integrated dewaxing-sintering vacuum furnace can ensure optimal quality and performance. These parts typically have complex shapes and high mechanical requirements; vacuum sintering guarantees a dense structure and stable performance.

Summary

The integrated dewaxing-sintering vacuum furnace is a core piece of equipment in carbide production, effectively improving production efficiency and ensuring product quality. It not only supports high-precision temperature control and vacuum management but also enhances carbide performance through pressure sintering, making it suitable for demanding applications such as cutting tools, molds, and mining tools.

If you are interested in this equipment or require further technical support, please contact us.