Vacuum Furnace for High-Temperature Alloy Heat Treatment

1. Introduction to Vacuum Furnaces

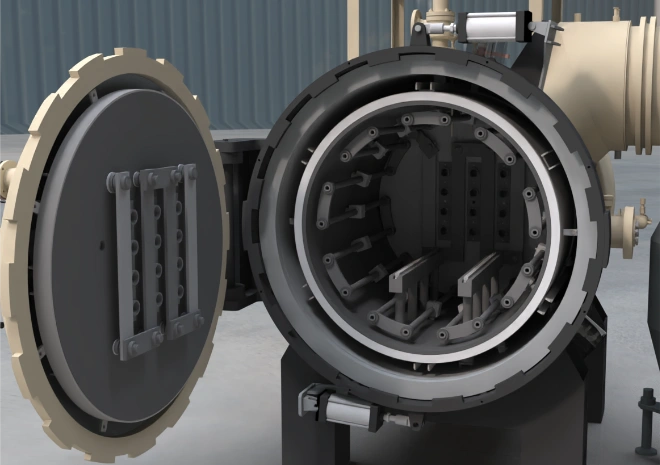

Vacuum furnaces are specialized industrial equipment designed to heat-treat materials in a controlled, oxygen-free environment. By eliminating air and other gases from the heating chamber, vacuum furnaces prevent oxidation and contamination, making them ideal for processing high-temperature alloys. These alloys, which include nickel-based, cobalt-based, and certain steel alloys, are critical in aerospace, power generation, and other high-performance industries.

2. Types and Configurations of Vacuum Furnaces

Vacuum furnaces come in various configurations, each tailored to specific applications:

Vacuum Resistance Furnaces: Utilize resistive heating elements and are suitable for temperatures up to 1,200°C.

Vacuum Induction Furnaces: Employ induction heating for faster heat-up rates and are ideal for melting and refining metals.

Vacuum Arc Furnaces: Use electric arcs for melting and are particularly effective for reactive and refractory metals.

Hybrid Vacuum Furnaces: Combine multiple heating methods for enhanced versatility.

3. Importance of Vacuum Heat Treatment for High-Temperature Alloys

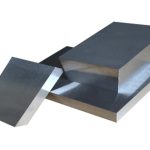

High-temperature alloys are subjected to extreme conditions and must maintain their mechanical properties, such as strength, ductility, and creep resistance. Vacuum heat treatment ensures these materials achieve the desired microstructure without contamination, which is crucial for their performance in demanding environments.

4. Key Technologies in Vacuum Furnaces

Vacuum Systems

The vacuum system is the heart of the furnace, responsible for creating and maintaining the required low-pressure environment. It typically consists of mechanical pumps, diffusion pumps, and gauges to monitor and control the vacuum level.

Heating Elements

Heating elements in vacuum furnaces can be resistive (using graphite, molybdenum, or tungsten) or inductive. The choice depends on the maximum temperature required and the heating rate.

Temperature Control Systems

Advanced temperature control systems, including PID controllers and thermocouples, ensure precise temperature regulation throughout the heat treatment process. This precision is vital for achieving consistent material properties.

5. Applications of Vacuum Furnaces in High-Temperature Alloy Processing

Vacuum furnaces are widely used for:

Solution Annealing: Dissolving precipitates and achieving a homogeneous structure.

Precipitation Hardening: Enhancing strength through controlled precipitation of secondary phases.

Stress Relieving: Reducing residual stresses to improve dimensional stability.

Sintering: Consolidating powdered metals into solid parts with minimal porosity.

6. Advantages of Vacuum Heat Treatment

Prevents Oxidation: Eliminates the need for protective atmospheres, reducing costs and complexity.

Enhanced Surface Quality: Produces clean, bright surfaces free from decarburization and scaling.

Improved Mechanical Properties: Achieves fine-grained microstructures, enhancing strength and ductility.

Versatility: Suitable for a wide range of materials and heat treatment processes.

7. Challenges and Limitations

High Initial Cost: Vacuum furnaces are expensive to purchase and maintain.

Complex Operation: Requires skilled operators to manage the vacuum and heating systems effectively.

Limited Size: The size of the vacuum chamber restricts the dimensions of the parts that can be processed.

8. Future Trends in Vacuum Furnace Technology

Advancements in vacuum furnace technology are focused on:

Increased Efficiency: Developing more energy-efficient heating and vacuum systems.

Enhanced Automation: Incorporating AI and machine learning for process optimization and control.

Improved Materials: Using advanced refractory materials to withstand higher temperatures and aggressive environments.

9. Summary

Vacuum furnaces play a critical role in the heat treatment of high-temperature alloys, ensuring these materials meet the stringent requirements of aerospace, power generation, and other high-performance industries. By providing a contamination-free environment, vacuum furnaces enable the production of alloys with superior mechanical properties and surface quality. Despite their high cost and operational complexity, the benefits they offer make them indispensable in modern manufacturing.

10. Frequently Asked Questions (FAQ)

Q: What are the primary benefits of using a vacuum furnace for high-temperature alloy heat treatment?A: The primary benefits include preventing oxidation, enhancing surface quality, improving mechanical properties, and offering versatility in processing various materials and heat treatments.

Q: How does a vacuum furnace prevent contamination during heat treatment?A: A vacuum furnace prevents contamination by creating a low-pressure environment that eliminates air and other gases, thus avoiding oxidation and interaction with impurities.

Q: What types of heating elements are used in vacuum furnaces?A: Heating elements in vacuum furnaces can be resistive (using graphite, molybdenum, or tungsten) or inductive, depending on the maximum temperature and heating rate required.

Q: What is the maximum temperature that can be achieved in a vacuum furnace?A: The maximum temperature varies by furnace type but can reach up to 3,000°C for high-end models using advanced heating elements.

Q: Are vacuum furnaces suitable for all types of high-temperature alloys?A: Yes, vacuum furnaces are suitable for a wide range of high-temperature alloys, including nickel-based, cobalt-based, and certain steel alloys, due to their ability to prevent oxidation and contamination.

Q: What are the main challenges associated with using vacuum furnaces?A: The main challenges include high initial costs, complex operation requiring skilled personnel, and limitations on the size of parts that can be processed.

Q: How do vacuum furnaces contribute to the aerospace industry?A: Vacuum furnaces contribute to the aerospace industry by producing high-temperature alloys with superior mechanical properties and surface quality, essential for components subjected to extreme conditions.

Q: What advancements are being made in vacuum furnace technology?A: Advancements include increased efficiency through better heating and vacuum systems, enhanced automation with AI and machine learning, and the use of improved refractory materials.

Q: Can vacuum furnaces be used for processes other than heat treatment?A: Yes, vacuum furnaces are also used for sintering, brazing, and other processes that require a contamination-free environment.

Q: What is the role of temperature control systems in vacuum furnaces?A: Temperature control systems ensure precise temperature regulation throughout the heat treatment process, which is vital for achieving consistent material properties and high-quality results.