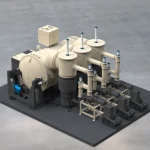

Vacuum Furnace for Ceramic Metallization and Brazing

1.Introduction: The Role of Vacuum Furnaces in Advanced Ceramic Processing

Vacuum furnaces are essential for high-precision ceramic applications like metallization and brazing. Operating under reduced pressure, they eliminate oxygen and impurities, ensuring strong, defect-free bonds. This is critical in aerospace, medical devices, and electronics, where components face extreme stress or biological environments. Unlike traditional methods, vacuum processing prevents oxidation, improves metal wetting, and enhances bond strength, making it indispensable for reliability-driven industries.

2.How Vacuum Furnaces Enable Superior Ceramic Metallization and Brazing

Ceramic metallization applies conductive layers to ceramics, while brazing joins ceramics to metals using filler materials. Atmospheric processing risks oxidation, leading to weak bonds. Vacuum furnaces create an oxygen-free environment, allowing metals like titanium or silver-copper-titanium alloys to adhere uniformly. This produces hermetic seals for electronics, durable aerospace parts, and biocompatible medical implants. Precise temperature control minimizes thermal stress, preventing cracks in brittle ceramics during heating or cooling.

3.Key Components of Vacuum Furnaces for Ceramic Applications

Vacuum System: Mechanical roughing pumps and high-vacuum diffusion/turbomolecular pumps achieve pressures as low as 10⁻⁶ mbar. Helium leak detectors ensure airtight seals, while gate and throttle valves regulate pressure.

Heating Elements: Graphite or molybdenum disilicide elements provide uniform temperatures up to 2,000°C, monitored by thermocouples and pyrometers with ±1°C accuracy. PID controllers adjust power for precise ramp/soak profiles.

Chamber Design: Stainless steel or Inconel chambers resist thermal stress, with water-cooled jackets protecting external components.

Gas Management: Inert gases like argon are introduced for controlled cooling or partial pressure processes, ensuring uniformity without turbulence.

4.Why Vacuum Furnaces Outperform Alternatives in Bond Quality

Vacuum environments eliminate oxidation and impurities, critical for metallization and brazing. In aerospace, vacuum-brazed ceramic coatings resist delamination under extreme heat. Medical implants benefit from oxidation-free joints between ceramics and metal stems, reducing rejection risks. Uniform heating prevents thermal gradients that could crack ceramics, ensuring reliability in high-stress applications.

5.Limitations of Vacuum Furnace Technology

High Costs: Initial investment is 2–3 times that of atmospheric furnaces due to complex vacuum systems and precision controls.

Slower Cycles: Pumping and controlled cooling extend processing time, reducing throughput.

Maintenance Complexity: Pump servicing and chamber inspections are frequent and costly.

Material Constraints: High-porosity ceramics may outgas excessively, complicating vacuum maintenance.

6.Comparison with Atmospheric and Inert Gas Furnaces

Atmospheric furnaces are cheaper and faster but risk oxidation, weakening bonds in critical applications. Inert gas furnaces reduce oxidation by flooding chambers with argon or nitrogen, but cannot match vacuum furnaces in eliminating impurities. This makes them less suitable for aerospace brazing or medical implant manufacturing, where flawless bonds are non-negotiable.

7.Real-World Applications of Vacuum Furnaces

Aerospace: Brazing ceramic heat shields and turbine blades for engines and re-entry vehicles.

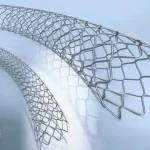

Medical Devices: Joining ceramic hip joints to metal stems, ensuring biocompatibility and longevity.

Electronics: Metallizing alumina substrates for power modules in electric vehicles and renewable energy systems, optimizing thermal and electrical conductivity.

8.Advantages and Disadvantages of Vacuum Furnaces

Pros:

Superior bond quality and purity.

Minimal contamination risks.

Precise temperature control for delicate ceramics.

Cons:

High capital and operational costs.

Slower production rates.

Complex maintenance requirements.

9.Choosing the Right Furnace for Ceramic Processing

Vacuum furnaces are ideal for applications demanding flawless bonds, such as aerospace components or medical implants. For lower-cost or high-volume processes where minor oxidation is acceptable, inert gas furnaces may suffice. Evaluate bond strength requirements, production volume, and budget to determine the optimal solution.

10.Frequently Asked Questions (FAQ)

Q: What distinguishes vacuum furnaces from atmospheric furnaces in ceramic brazing?

A: Vacuum furnaces eliminate oxidation, enabling stronger, purer bonds, while atmospheric furnaces risk contamination but are cheaper and faster.

Q: Which industries rely most on vacuum furnace technology?

A: Aerospace, medical devices, electronics, and automotive sectors depend on them for precision bonding.

Q: Why choose vacuum brazing over inert gas brazing?

A: Vacuum brazing provides superior bond purity and strength for critical applications like aerospace engines.

Q: How does temperature uniformity affect ceramic brazing?

A: Uniform heating prevents thermal stress and cracks in brittle ceramics, ensuring reliable bonds.

Q: Are vacuum furnaces suitable for large ceramic components?

A: Yes, but chamber size and pump capacity limit maximum dimensions, making them better for medium-to-small parts.

Q: What makes vacuum furnaces ideal for medical implants?

A: They produce biocompatible, oxidation-free bonds, reducing implant failure risks.

Q: Can vacuum furnaces process ceramics and metals together?

A: Absolutely. They excel at joining dissimilar materials via brazing or sintering.

Q: What are the main drawbacks of vacuum furnace processing?

A: High costs, longer cycles, and maintenance complexity (e.g., pump servicing) are significant challenges.

Q: How do operational costs compare to atmospheric methods?

A: Vacuum furnaces cost 2–3 times more upfront and consume more energy, but justify expenses through superior bond quality.