Vacuum furnace for annealing stainless steel parts

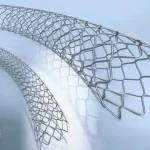

Stainless steel is one of the most widely used materials in modern industry due to its excellent corrosion resistance, mechanical strength, and decorative appearance. However, during cold working or machining, stainless steel often develops internal stress and surface oxidation problems. To restore its ductility, improve corrosion resistance, and maintain a bright surface finish, vacuum bright annealing is the ideal solution.

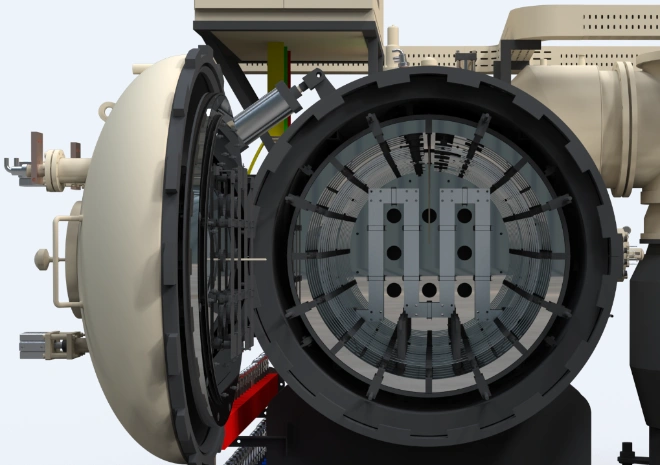

Vacuum annealing furnaces are specifically designed to provide a controlled heat treatment environment, ensuring that stainless steel parts achieve a bright, oxide-free surface and stable mechanical properties. Compared to traditional annealing in air or protective atmosphere, vacuum annealing eliminates oxidation, discoloration, and the need for secondary surface treatment.

The Vacuum Annealing Process for Stainless Steel

The annealing process for stainless steel parts generally involves several key stages:

Stage 1: Heating

The stainless steel components are slowly heated inside the vacuum furnace. With precise temperature control and uniform heating, the parts are protected from thermal stress and distortion.

Stage 2: Soaking

Once the target annealing temperature is reached (typically in the range of 1040–1100°C for austenitic stainless steels), the workpieces are held for a defined period. This allows the internal structure to fully recrystallize, eliminating residual stress.

Stage 3: Cooling

After soaking, the furnace chamber is cooled under vacuum or with inert gas (such as nitrogen or argon). This prevents oxidation, ensuring the parts exit the furnace with a clean, metallic luster—hence the term bright annealing.

Advantages of Vacuum Annealing for Stainless Steel Parts

Bright surface finish: No oxidation or discoloration, eliminating the need for pickling or polishing.

Improved corrosion resistance: By removing residual stress and ensuring a clean surface, stainless steel maintains optimal resistance in harsh environments.

Dimensional stability: Uniform heating and cooling minimize deformation, which is especially important for precision components.

Efficient and clean process: Vacuum heat treatment is environmentally friendly, with no scale or harmful emissions.

Typical Furnace Specifications

SIMUWU’s RVA series vacuum annealing furnaces are designed for stainless steel parts, offering high performance and reliability. Depending on customer needs, different models are available:

| Model | Effective Working Zone (W×H×L mm) | Max. Temperature | Ultimate Pressure | Temperature Uniformity | Loading Capacity |

|---|---|---|---|---|---|

| RVA-446 | 400×400×600 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 200 kg |

| RVA-557 | 500×500×700 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 300 kg |

| RVA-669 | 600×600×900 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 500 kg |

| RVA-7710 | 700×700×1000 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 700 kg |

| RVA-8812 | 800×800×1200 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 1000 kg |

| RVA-9915 | 900×900×1500 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 1200 kg |

| RVA-121225 | 1200×1200×2500 | 1300 ℃ | 2×10⁻³ Pa | ±5 ℃ | 1500 kg |

These furnaces can be tailored to meet different production requirements—from small precision parts to large stainless steel components.

Why Choose SIMUWU?

With over 10 years of professional experience in the vacuum heat treatment industry, SIMUWU provides reliable and efficient furnace solutions. Our product line includes vacuum annealing furnaces, vacuum gas quenching furnaces, vacuum brazing furnaces, and vacuum sintering furnaces, which are trusted by users worldwide.

Our team of technical experts ensures that every furnace is optimized for customer-specific applications, delivering stable operation, high product quality, and strong after-sales support.

Welcome to visit our website for other vacuum furnace products

Or contact us directly at kevin.liu@vacfurnace.com