Introduction: Why Vacuum Brazing Furnace Is Critical for Stainless Steel

When joining stainless steel components, oxidation is a major challenge. A vacuum brazing furnace eliminates oxygen, delivering bright, strong, and contamination-free joints. This makes it an ideal choice for manufacturers producing stainless steel heat exchangers, medical tools, or precision parts.

What Is a Vacuum Brazing Furnace?

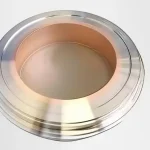

A vacuum brazing furnace is a specialized piece of equipment that heats metal components in a vacuum or controlled atmosphere until the filler metal melts and bonds the parts together. Unlike open-flame or controlled-atmosphere brazing, this process achieves flux-free, perfectly clean results.

How Vacuum Brazing Works Step by Step

Loading: Stainless steel parts are placed on fixtures inside the furnace chamber.

Evacuation: The vacuum system removes oxygen and moisture to prevent oxidation.

Heating: The chamber heats to a controlled temperature (850°C–1250°C).

Brazing: Filler metal melts and flows into the joint by capillary action.

Cooling: Controlled cooling under vacuum or inert gas prevents discoloration.

Unloading: Finished parts are bright, clean, and ready for use — no cleaning required.

Key Advantages of Vacuum Brazing for Stainless Steel Parts

1. High Joint Strength and Durability

Vacuum brazing creates strong metallurgical bonds, critical for components under mechanical stress, such as stainless steel manifolds or structural parts.

2. Perfectly Clean, Oxide-Free Surfaces

The vacuum environment prevents oxidation, producing shiny, aesthetically perfect joints without additional polishing or pickling.

3. Precise Temperature Control and Minimal Distortion

Industrial vacuum brazing furnaces use advanced PID controllers to maintain even temperatures, reducing warping and ensuring dimensional accuracy.

4. Cost Savings from Reduced Post-Processing

No flux residues mean no chemical cleaning. This saves time, reduces waste treatment costs, and protects surface finish.

Comparing Vacuum Brazing Furnace vs. Conventional Brazing

| Aspect | Conventional Brazing | Vacuum Brazing Furnace |

|---|---|---|

| Atmosphere | Air or protective gas | High vacuum or inert gas |

| Joint Cleanliness | Requires post-cleaning | Bright, flux-free |

| Dimensional Control | Moderate | Excellent |

| Oxidation Risk | High | Nearly zero |

| Long-Term Cost | Higher due to cleaning | Lower over time |

Types of Industrial Vacuum Brazing Furnaces

Horizontal Vacuum Brazing Furnace: Best for medium production batches and easy loading.

Vertical Vacuum Brazing Furnace: Ensures superior temperature uniformity for critical aerospace or medical parts.

Continuous Vacuum Brazing Furnace: Designed for high-volume automated production.

Applications Beyond Stainless Steel

While stainless steel is a primary use case, vacuum brazing furnaces are also suitable for:

Titanium and nickel alloys (aerospace & medical)

Copper and brass (heat exchangers)

Carbide and tool steel (cutting inserts, molds)

Dissimilar metal joining for electronic components

Choosing the Right Vacuum Brazing Furnace Manufacturer

When selecting a supplier, consider:

Experience in stainless steel brazing solutions

Furnace size and customization options

Process control systems (data logging, remote monitoring)

After-sales service and global technical support

Advantages and Disadvantages of Vacuum Brazing Technology

Advantages of Vacuum Brazing

Clean, flux-free joints

High precision and consistency

Suitable for sensitive alloys

Reduced post-processing and labor costs

Disadvantages of Vacuum Brazing

Higher equipment investment

Longer production cycle compared to simple torch brazing

Requires trained operators

Summary: Why Vacuum Brazing Is the Best Choice

For manufacturers seeking a reliable stainless steel brazing solution, a vacuum brazing furnace offers unmatched joint quality, reduced rework, and superior process repeatability. Despite the initial investment, the long-term cost savings and improved product performance make it the preferred joining technology.

Frequently Asked Questions (FAQ)

Q: Why use a vacuum brazing furnace for stainless steel parts?

A: It prevents oxidation, creates bright joints, and eliminates post-cleaning steps.

Q: Can a vacuum brazing furnace process other metals?

A: Yes, it works for titanium, nickel alloys, copper, and dissimilar metals.

Q: How does vacuum brazing improve production efficiency?

A: By reducing rework, scrap, and chemical cleaning, saving labor and time.

Q: What industries benefit from vacuum brazing?

A: Aerospace, medical, automotive, electronics, and power generation.

Q: Is the process compatible with mass production?

A: Yes, continuous vacuum brazing furnaces can run automated, high-volume cycles.

Q: How hot does a vacuum brazing furnace operate?

A: Typically between 850°C–1250°C, depending on filler metal and base alloy.

Q: What should I look for in a vacuum brazing furnace manufacturer?

A: Proven expertise, customization options, reliable service, and process support.