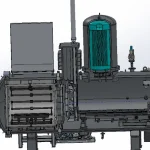

1. Introduction to Vacuum Annealing Furnaces

A vacuum annealing furnace is a vacuum heat treatment device specifically designed to eliminate residual stress within metallic materials, improve their microstructure, and thus enhance their overall performance.

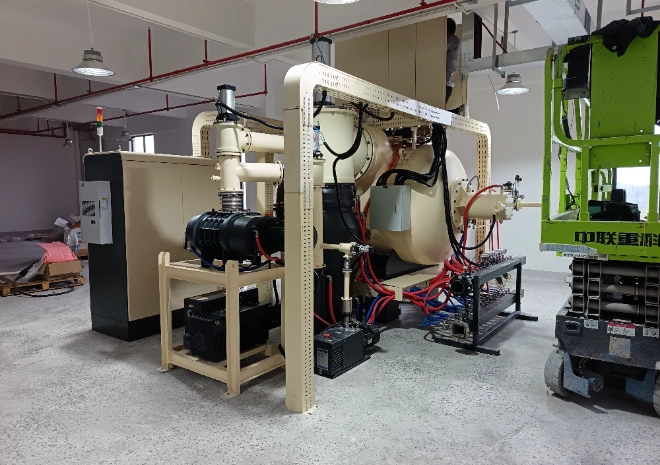

2. Core Components

Double-layer vacuum chamber

Radiant heating system

High vacuum pump assembly

Precision temperature control

Gas refill system (argon/nitrogen)

3. Operational Safety

Never open the chamber above 150°C

Wear heat-resistant gloves and safety goggles

Maintain a 2-meter distance around the exhaust port

Emergency Response

Power failure: Activate the emergency cooling system

Vacuum drop: Trigger automatic gas refill

Overheating: Activate the emergency venting procedure

Hazardous Material Handling Procedures

Store cleaning solvents in designated fireproof cabinets

Dispose of waste vacuum pump oil according to local regulations

Affix contents and hazard warning labels to all gas cylinders

4.Troubleshooting Guide

| Symptom | Probable Cause | Solution |

|---|---|---|

| Slow vacuum pumping | Contaminated pump oil | Replace oil and install filters |

| Temperature overshoot | Faulty PID controller | Recalibrate control parameters |

| Uneven heating | Damaged heating element | Replace affected zone |

| Gas backfill instability | Leaky regulator | Replace seals and test pressure |

| PLC error code E-05 | Sensor failure | Replace thermocouple/pressure transducer |

5. Summary

Vacuum annealing furnaces provide superior material properties through contamination-free processing and precise thermal control. Regular maintenance and proper operation can extend equipment lifespan by 40-60% while ensuring consistent product quality. Implementation of predictive maintenance strategies can reduce unplanned downtime by up to 75%.

Learn more:

Vacuum Annealing Furnace

6. Frequently Asked Questions (FAQ)

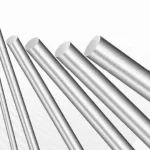

Q: What materials are best suited for vacuum annealing?

A: Stainless steels, titanium alloys, nickel-based superalloys, and precision bearings.

Q: How does vacuum level affect annealing results?

A: Higher vacuum (10⁻⁴ Pa) reduces oxidation and improves surface finish by 30-50% compared to 10⁻² Pa.

Q: What maintenance intervals are critical?

A: Heating element inspection every 500 cycles, diffusion pump oil replacement every 2000 hours, and chamber leak testing quarterly.

Q: Can this furnace replace traditional air annealing?

A: Yes, for applications requiring cleaner surfaces (<0.2μm oxidation) and tighter dimensional control (±0.02% distortion).

Q: What safety certifications are required for operators?

A: Certified Vacuum Furnace Technician (CVFT) training in pressure vessel operation and emergency response is recommended.