In the production of medical devices, the performance requirements for materials are extremely stringent. Stainless steel, a common material in medical devices, requires optimization of its corrosion resistance, strength, toughness, and biocompatibility through precise heat treatment processes. Vacuum annealing furnaces, as efficient and precise heat treatment equipment, are widely used for the annealing and hardening of high-performance materials such as stainless steel.

Working Principle of a Vacuum Annealing Furnace

A vacuum annealing furnace heats the workpiece in a low-pressure environment, allowing it to heat and cool under conditions free from oxygen or other gas contaminants. This annealing method effectively prevents surface oxidation, maintaining the surface smoothness and corrosion resistance of stainless steel. Its working process mainly includes the following steps:

1. Preheating Stage

Preheating is performed first during the annealing process to avoid material deformation caused by thermal shock. The preheating temperature is typically set between 500℃ and 700℃ to ensure uniform workpiece temperature and prepare for subsequent heating processes.

2. Austenitizing Heating

The stainless steel is heated to the austenitizing temperature, typically between 1000℃ and 1150℃, through precise temperature control. At this temperature, the crystal structure of stainless steel changes, becoming more uniform, which facilitates subsequent annealing.

3. Cooling Stage

Cooling is performed in a vacuum environment using high-purity nitrogen or argon gas. By controlling the cooling rate, the hardness and toughness of the stainless steel can be optimized. Especially in medical devices, precise control of the cooling process is crucial to ensuring the performance of stainless steel materials.

Key Technical Parameters of Vacuum Annealing Furnaces

To ensure the efficiency and precision of the vacuum annealing process, the design of the vacuum annealing furnace needs to meet a series of stringent technical parameters. The following are the key technical parameters of vacuum annealing furnaces suitable for stainless steel used in medical devices:

| Model | Effective Working Zone(W*H*L) | MAX.Temperature | Ultimate Pressure | Temperature Uniformity | Loading Capacity |

| RVA-446 | 400*400*600mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 200kg |

| RVA-557 | 500*500*700mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 300kg |

| RVA-669 | 600*600*900mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 500kg |

| RVA-7710 | 700*700*1000mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 700kg |

| RVA-8812 | 800*800*1200mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 1000kg |

| RVA-9915 | 900*900*1500mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 1200kg |

| RVA-121225 | 1200*1200*2500mm | 1300 ℃ | 2*10-3 Pa | ±5℃ | 1500kg |

| Remark: The working zone of equipment could be customized base on customer’s production. | |||||

Applications in Medical Devices

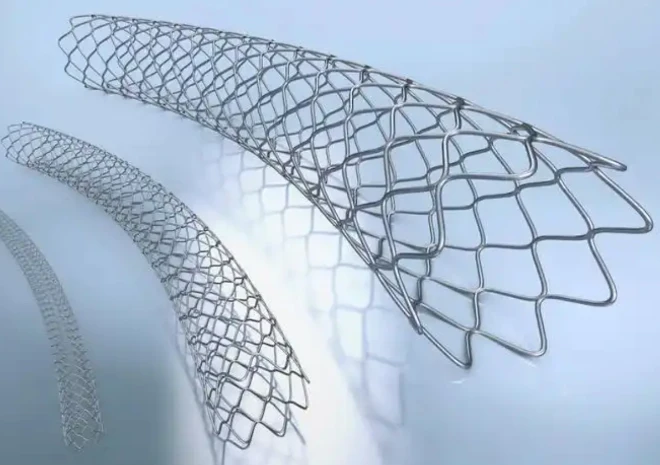

Stainless steel has a wide range of applications in the medical device field, especially in surgical instruments and implants. Through precise vacuum annealing, the strength, hardness, and corrosion resistance of stainless steel can be improved, while maintaining its good toughness and biocompatibility. Specific applications include:

1. Surgical Instruments

Surgical instruments such as scalpels, scissors, and forceps require extremely high hardness and wear resistance, while also possessing good corrosion resistance. Vacuum annealing furnaces can effectively improve the surface quality and long-term durability of these instruments. 2. Implants

In the manufacture of medical implants such as joint prostheses and dental implants, stainless steel materials require precise heat treatment to achieve optimal mechanical properties and biocompatibility. Vacuum annealing processes can prevent surface contamination of implants and improve their biocompatibility.

Conclusion As the core equipment for heat treatment of stainless steel in medical devices, the vacuum annealing furnace features precise temperature control and a favorable vacuum environment, effectively improving the various properties of stainless steel materials and meeting the stringent requirements of medical devices for high strength, high corrosion resistance, and biocompatibility.

If you have any needs or technical inquiries regarding vacuum annealing furnaces suitable for stainless steel in medical devices, please feel free to contact us.