1. Introduction

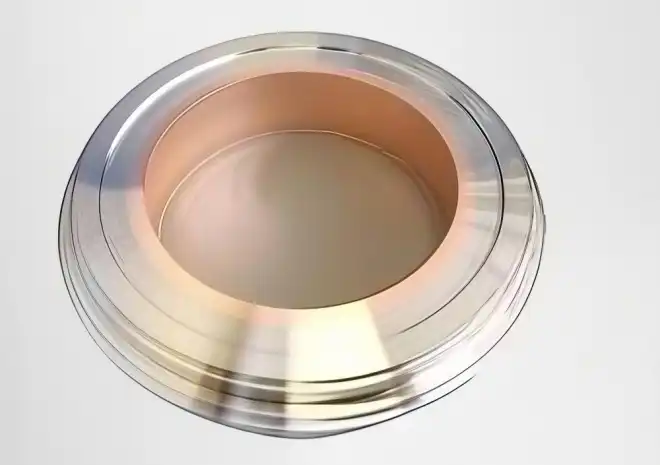

In modern precision manufacturing, joining “high-thermal-conductivity copper” with “high-strength stainless steel” can easily lead to stress cracks due to the difference in their thermal expansion coefficients. Vacuum brazing technology provides a standard solution to this problem. This process has been widely applied to core components such as vacuum power switches, semiconductor water-cooled heat sinks, aerospace pipelines, and medical linear accelerators.

2. Why choose vacuum brazing?

- 1. Extremely high airtightness: The welds are dense and free of pores, easily handling ultra-high vacuum and high-pressure environments.

- 2. Complementary performance: Perfectly retains the electrical and thermal conductivity of copper while also providing the structural strength of stainless steel.

- 3. Pure and pollution-free: No flux is required, and the surface remains bright and clean after welding, eliminating the need for secondary cleaning.

3. Typical Brazing Parameters and Furnace Requirements

If you want to perform this vacuum brazing process, you need to use 560 silver as the brazing filler metal and perform the following steps in a vacuum brazing furnace:

- 1. Initial vacuum pumping: Room temperature, time: 30-60 minutes. Heating should only begin after the furnace reaches 6.7*10^-3 Pa.

- 2. Preheating: Temperature: 450℃, time: 20-40 minutes, to reduce the temperature difference within the workpiece.

- 3. Second preheating: Temperature: 650℃, time: 20-30 minutes, to further purify the metal surface.

- 4. Brazing and holding: Temperature: 760℃, time: 10-20 minutes, for brazing. The holding time should not be too long.

- 5. Slow cooling: Temperature: Gradually reduced to <100℃, slow cooling in the furnace to prevent cracking of the weld seam.

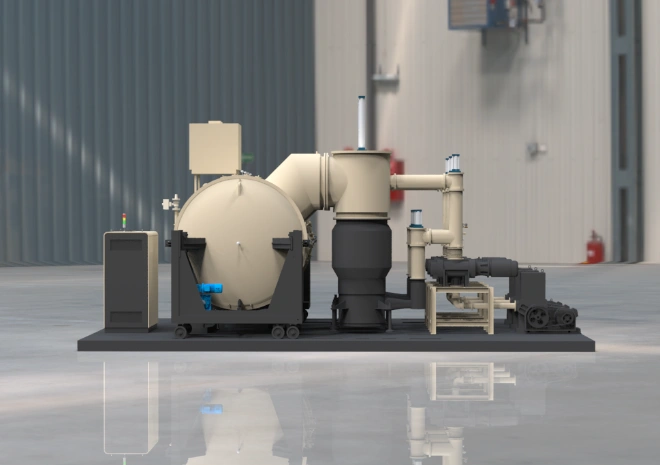

4. SIMUWU Vacuum Brazing Furnace Configuration

The following are the specific parameters of the SIMUWU vacuum brazing furnace required for this vacuum brazing process:

| Furnace type | Horizontal type,single chamber, internal recycle |

| Max. Loading weight | 500kg (including jig) |

| Ultimate vacuum | 6.7×10-4pa |

| Pressure rise rate (empty furnace, cold state) | ≤0.67Pa/h |

| Max.design temperature | 850℃ |

| Working temperature | 800℃ |

| Heating rate(The room temperature of the empty furnace rises to 800℃) | ≤ 40min |

| Temperature uniformity | 9 points temp testing (±5℃) |

| Temperature rising rate(with workpiece) | 15-20℃/min |

| Effective working zone size( mm) | 600×600×900(W*H*L) |

If you have any needs or questions, please feel to contact us. I will be at your service.