Introduction to SKH9 Material Performance

SKH9 (equivalent to AISI M2), a representative grade of molybdenum-based high-speed steel, has consistently held a core position in precision cutting tools and high-end cold work molds due to its excellent red hardness and wear resistance. However, the stringent requirements for temperature field uniformity, oxidation control, and cooling rate during its heat treatment process have long limited its performance. SIMUWU vacuum furnaces, with their precise temperature control and process adaptability, have developed a dedicated heat treatment solution for SKH9, achieving breakthroughs in both material performance and production efficiency, providing reliable technical support for high-end manufacturing.

Core Challenges and SIMUWU Solutions

The core performance of SKH9 depends on the complete dissolution of carbides during the austenitizing stage and the effective elimination of retained austenite during the tempering stage, while simultaneously preventing the volatilization of alloying elements such as tungsten and molybdenum. SIMUWU vacuum furnaces isolate oxidizing media with a high-vacuum environment, preventing surface decarburization; a multi-zone independent PID temperature control system and dynamic thermal field balancing algorithm achieve a temperature difference of ≤±0.5℃ inside the furnace, precisely matching the segmented heating requirements of SKH9; and an adjustable high-pressure gas cooling system can dynamically adjust the cooling rate according to the workpiece size, balancing hardness and toughness.

Experimental Process Parameters for SKH9

Based on the SKH9-adapted process using SIMUWU vacuum furnaces (taking the RVGQ series as an example), the experimentally verified parameter system covers preheating, quenching, and tempering processes. The specific parameters are as follows:

| Process Stages | Temperature Range | Vacuum level | Holding time (min/mm) | Cooling/ Atmosphere |

Core Objectives |

|---|---|---|---|---|---|

| Preheating I | 500~550℃ | 10⁻¹~10⁻² Pa | 1.2~1.5 min/mm | Vacuum environment, furnace heating | To relieve stress and prevent cracking due to thermal shock at high temperatures. |

| Preheating II | 880~900℃ | 10⁻¹~10⁻² Pa | 1.2~1.5 min/mm | Vacuum environment, furnace heating | To reduce temperature differences and prepare for austenitization. |

| Quenching Heating | 1210~1230℃ | 10⁻²~10⁻³ Pa | 0.6~0.8 min/mm | High vacuum environment, to prevent volatilization of alloying elements | To achieve complete dissolution of carbides and refine the grain structure. |

| Quenching Cooling | Room temp | Vent to atmospheric pressure | – | High-purity N₂ (≥99.999%), pressure 0.6~1.0 MPa, cooling rate ≥50℃/s | To promote martensitic transformation and reduce deformation. |

| Tempering (3 times) | 550~570℃ | Atmospheric pressure | 2 hours/cycle | Slightly positive pressure N₂ (0.1~0.2 MPa), forced air cooling | To eliminate retained austenite and stabilize hardness and microstructure. |

| Deep Cooling (optional) | -70~-80℃ | – | 2~4 hours | Nitrogen protection, slow cooling | To improve dimensional stability, with retained austenite ≤ 5%. |

Vacuum Quenching Control

To address common issues in SKH9 vacuum heat treatment, such as deformation, uneven hardness, and surface oxidation, SIMUWU vacuum furnace systems have developed a customized solution. Its three-stage pumping system with coordinated control technology maintains the vacuum level within ±1 Pa of the target value, preventing alloy element volatilization caused by vacuum fluctuations. The high-pressure gas cooling system, combined with forced convection fans, enables precisely adjustable cooling rates to accommodate SKH9 workpieces of different sizes. Thin parts (<5 mm) use flow-guiding plates to control gas flow and prevent cracking, while thick parts (>20 mm) increase gas pressure to 0.6–1.0 MPa to ensure sufficient hardenability during SKH9 vacuum quenching.

Application Results

Our customer, a precision cutting tool manufacturer, introduced the SIMUWU RVGQ series vacuum quenching furnace. As a result, SKH9 hardness was stabilized at 63–66 HRC, deformation was controlled within 0.02 mm per 100 mm, and service life increased by 40% compared with traditional processes. The surface quality eliminated the need for subsequent grinding, and overall production efficiency improved by more than 25%. In addition, the SIMUWU vacuum heat treatment furnace features excellent sealing performance and high cooling efficiency, significantly reducing nitrogen consumption. Combined with low power consumption and off-peak electricity usage strategies, comprehensive production costs were reduced by 22%–30%, achieving a balance between technical performance and economic efficiency.

Future Outlook

As high-end manufacturing continues to demand higher material performance, the integration of SKH9 and vacuum furnace technology will advance toward greater intelligence and customization. SIMUWU will continue to iterate thermal field control and process optimization technologies, developing dedicated parameter libraries for SKH9 workpieces used in cutting tools, molds, and wear-resistant components, as well as for other materials, enabling full-process visualization and control of heat treatment. In the future, these adaptation solutions are expected to expand to a wider range of materials, unlocking more possibilities for advanced equipment manufacturing applications.

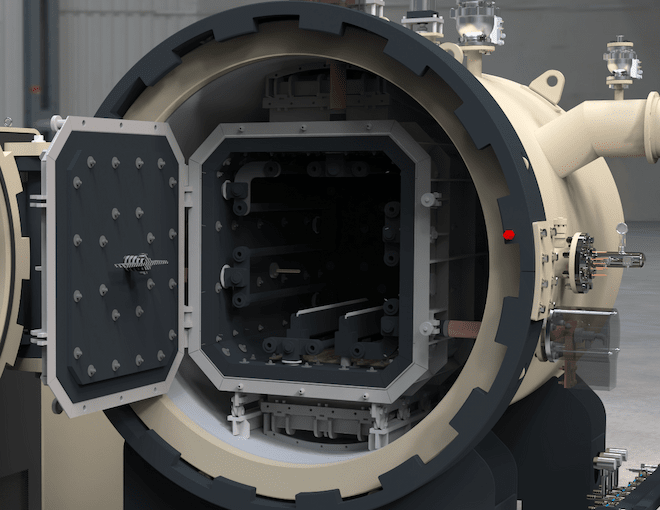

| Furnace type | Horizontal, single chamber, internal recycle |

| Loading method | Front loading |

| Max Loading size | 600×600×900(W×H×L mm) |

| Max Loading weight | 500kg |

| Power | 3phase; 380V;50Hz |

| Max design temperature | 1350℃ |

| Working temperature | 500-1300℃ |

| Heating element | High strength graphite |

| Pressure rising rate | ≤0.67Pa/h |

| Cooling method | Air cooling/Natural cooling |

| Cooling gas pressure | 6-15bar(abs) |

| Cooling gas | Nitrogen or Argon (purity: 99.99% or 99.999%) |

Recommended Equipment

The RVGQ series vacuum gas quenching furnace produced by SIMUWU is a high-quality product for vacuum heat treatment of tool steel, die steel, high-speed steel, ultra-high strength steel and other materials. Good temperature control accuracy and temperature control uniformity ensure the effective implementation of the vacuum gas quenching process.

Why Choose SIMUWU Vacuum Furnace?

SIMUWU focuses on the manufacture of vacuum furnaces, has more than ten years of relevant experience, and has a good reputation in the field of vacuum furnace manufacturing. The product line includes vacuum gas quenching furnaces, vacuum oil quenching furnaces, vacuum brazing furnaces, etc, which are widely sold in developed and developing countries. For detailed technical information, please click on the official website below: https://www.simuwufurnace.com/vacuum-gas-quenching-furnace/

If you want to know more about vacuum furnace equipment, please send your needs to the email kevin.liu@vacfurnace.com, and our company will give you a satisfactory solution.