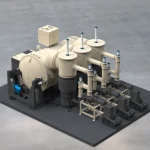

Simuwu Vacuum Gas Quenching Furnace Instructions

With the continuous advancement of technology, vacuum gas quenching furnaces are increasingly being used in modern industrial production and scientific research. To understand vacuum gas quenching furnaces, it’s helpful to first understand their operation. We’ll briefly explain the process:

I. Furnace Startup Preparation

1.1 Check that all electrical connectors are tight and that all components are clean and functioning properly.

1.2 Adjust control instruments to meet vacuum heat treatment process requirements.

1.3 Turn on the gas and water cooling switches.

1.4 Turn on the main power switch.

II. Furnace Startup Procedure

2.1 Turn on all water cooling system switches to ensure unobstructed drainage. During furnace operation, the drain temperature must not exceed 35°C to prevent scale accumulation.

2.2 Open the furnace door and transfer the workpiece into the heating chamber via a trolley. Then close the furnace door and secure the door lock. 2.3 Open the pipeline bleed valve for a short while, then close it. Open the bypass valve, start the slide valve pump, start the holding pump, and start the holding valve.

2.4 When the vacuum reaches 700 Pa (i.e., the Roots pump no longer rotates with the slide valve pump), start the Roots pump.

2.5 When the vacuum falls below 30 Pa, turn off the holding pump and the holding valve. Open the main valve and the diffusion pump heater to preheat the diffusion pump.

2.6 When the diffusion pump oil temperature reaches the standard temperature and the vacuum falls below 2 Pa, close the bypass valve and open the high-pressure valve.

2.7 When the vacuum reaches the set heating level, turn on the heater. The temperature will automatically increase and maintain according to the process settings. 2.8 After the insulation is complete, close the high-pressure valve when the gas filling temperature reaches the set point, heat the diffusion pump, start the holding pump and holding valve, and close the main valve, Roots pump, and slide valve pump.

2.9 If the workpiece requires nitrogen filling to cool it down, select the filling button in advance. The furnace will automatically fill with gas when the filling temperature is reached.

2.10 Fill the workpiece from negative pressure to slightly positive pressure, and start the fan.

2.11 Open the filling valve again for a second filling (until the maximum gas quenching pressure required by the process is reached) to achieve rapid cooling.

2.12 The material cooling time depends on the thickness of the material.

2.13 After the firing is over, open the bleed valve to discharge any remaining nitrogen from the furnace.

2.14 After the internal bleed is complete, close the bleed valve and start the vacuum unit to evacuate the workpiece. When the furnace pressure reaches the release ring condition, open the lock ring and close the vacuum unit. 2.15 Open the vent valve.

2.16 When the furnace pressure reaches atmospheric pressure, open the furnace lid and remove the workpiece.

III. Furnace Shutdown

3.1 Close the furnace lid and tighten the locking ring.

3.2 Open the bypass valve and evacuate the furnace to a certain pressure. Close the bypass valve and turn off the mechanical pump.

3.3 Turn off the nitrogen switch.

3.5 Turn off the water supply and all shut-off valves.

3.5 Turn off the main power switch.

Note: All steps must be performed with the locking ring locked. It is strictly forbidden to perform any steps with the locking ring open.

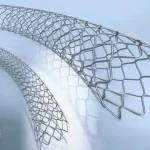

The RVGQ series vacuum gas quenching furnaces manufactured by SIMUWU are high-quality products for vacuum heat treatment of materials such as tool steel, die steel, high-speed steel, and ultra-high-strength steel. Excellent temperature control accuracy and uniformity ensure an efficient vacuum gas quenching process. SIMUWU specializes in vacuum furnace manufacturing, with over a decade of experience and an excellent reputation in the field. Our product line includes vacuum gas quenching furnaces, vacuum oil quenching furnaces, vacuum brazing furnaces, etc., which are widely sold in developed and developing countries. You can click on the Vacuum Gas Quenching Furnace product details page to view detailed technical information: