SIMUWU Vacuum Furnace – Commercial Vacuum Furnace Manufacturer

1. Introduction

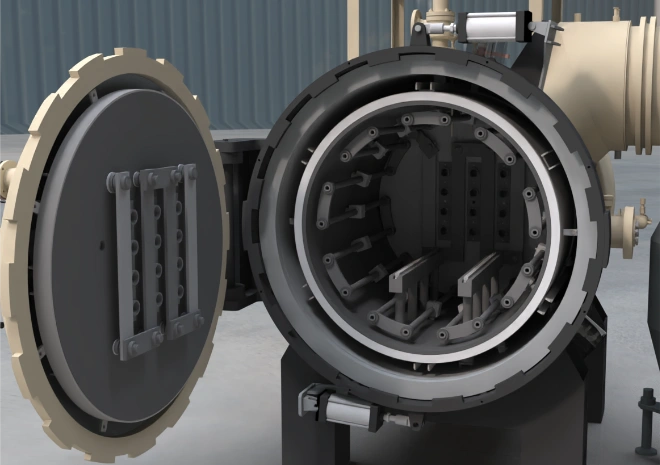

SIMUWU is a trusted name in the heat treatment industry, known for manufacturing high-quality vacuum furnaces. These advanced furnaces are used across various industries for heat treating materials in a controlled vacuum environment. SIMUWU’s commercial vacuum furnaces offer numerous benefits, including precise temperature control, enhanced material properties, and oxidation prevention. This article explores SIMUWU’s vacuum furnaces, highlighting their efficiency, benefits, and applications.

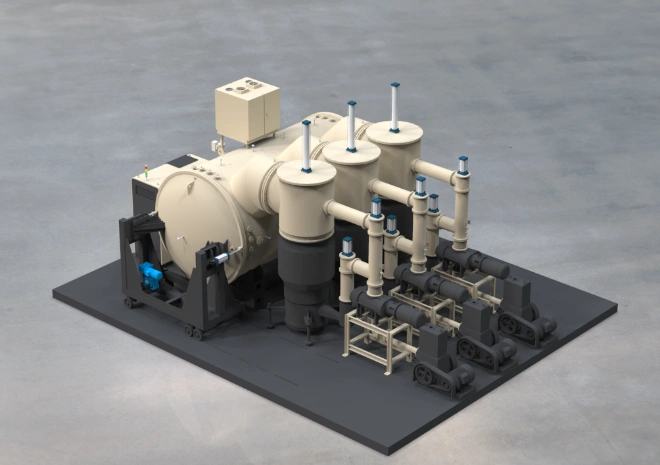

2. What Makes SIMUWU’s Vacuum Furnace Efficient?

Efficiency is key when it comes to vacuum furnaces, and SIMUWU has engineered its furnaces to be among the most energy-efficient in the industry. The SIMUWU vacuum furnace is designed with state-of-the-art insulation materials and advanced temperature control systems that help reduce energy consumption while maintaining optimal heat treatment conditions. The furnace’s design ensures uniform heat distribution, minimizing energy waste and improving the quality of the treated materials.

In addition to energy efficiency, SIMUWU vacuum furnaces are equipped with automated control systems that optimize the heating and cooling cycles, providing more precise control over the entire heat treatment process. This results in faster processing times, increased production capacity, and lower operational costs.

3. Types of SIMUWU Vacuum Furnaces

SIMUWU offers a variety of vacuum furnaces tailored to meet the needs of different industries. Some of the most efficient and widely used models include:

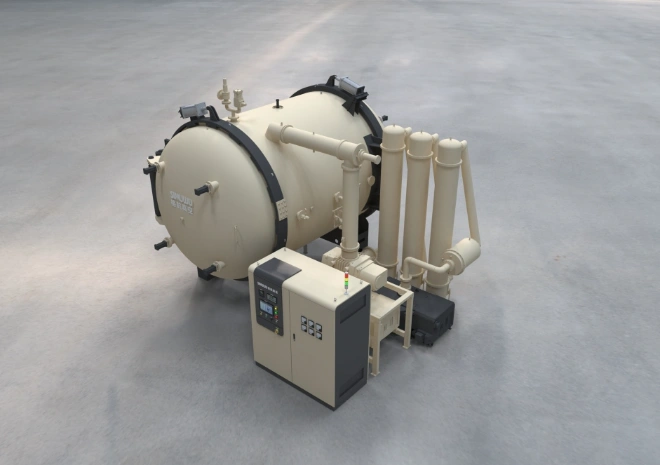

The SIMUWU Vacuum Heat Treatment Furnace

The SIMUWU vacuum heat treatment furnace is designed for general heat treatment applications such as hardening, annealing, and tempering. This furnace offers precise control over temperature and atmosphere, allowing for uniform heat distribution that reduces energy consumption. The vacuum heat treatment furnace is ideal for industries requiring high-quality results with minimal oxidation or contamination.

The SIMUWU Vacuum Sintering Furnace

The SIMUWU vacuum sintering furnace is designed for powder metallurgy applications. It operates in a vacuum environment, ensuring that no oxidation occurs during the sintering process. These furnaces feature advanced heating systems that significantly reduce heat-up and cool-down times, resulting in higher energy efficiency and improved material integrity.

The SIMUWU Vacuum Brazing Furnace

The SIMUWU vacuum brazing furnace is engineered for high-precision joining of metals and ceramics in a contamination-free environment. It operates under vacuum or controlled gas atmospheres, eliminating oxidation and ensuring clean, void-free brazed joints. These furnaces integrate advanced temperature control systems and uniform heating technology, enabling precise management of brazing cycles to optimize joint strength and material properties.

The SIMUWU Customizable Vacuum Furnace

For industries with specific needs, SIMUWU offers customizable vacuum furnaces. These furnaces can be tailored to meet the exact temperature, pressure, and processing time requirements of different materials. With advanced automation and energy-efficient design, SIMUWU’s customizable vacuum furnaces ensure optimal performance while reducing energy consumption.

4. Why SIMUWU Vacuum Furnaces Are Preferred

SIMUWU’s commercial vacuum furnaces are highly regarded across various industries for their efficiency and precision. The key reasons why manufacturers choose SIMUWU include:

Superior Quality

SIMUWU’s vacuum furnaces provide exceptional heat treatment quality by ensuring uniform heating and precise temperature control. This consistency leads to improved material properties, reduced defects, and higher-quality products.

Energy Efficiency

SIMUWU’s vacuum furnaces are designed to be energy-efficient, which helps reduce operational costs. By optimizing heating cycles and incorporating energy recovery systems, SIMUWU ensures that its furnaces use less energy, which is especially valuable in high-volume production environments.

Customization Options

SIMUWU offers customizable vacuum furnaces that are specifically tailored to meet the needs of different industries. Whether it’s for aerospace, automotive, or medical applications, SIMUWU provides a furnace that suits the specific requirements of each customer.

Reliability and Durability

SIMUWU’s vacuum furnaces are built with high-quality materials and advanced technology, ensuring long-lasting performance and minimal downtime. These furnaces are designed to withstand demanding heat treatment processes, making them a reliable choice for industrial applications.

5. Applications of SIMUWU Vacuum Furnaces

SIMUWU’s vacuum furnaces are used in a variety of industries for applications such as:

Aerospace

The aerospace industry requires materials that can withstand extreme conditions. SIMUWU’s vacuum furnaces are used to treat parts such as turbine blades, engine components, and other high-strength materials that need to maintain dimensional accuracy and surface quality.

Automotive

In the automotive industry, SIMUWU’s vacuum furnaces are used for heat treating parts like gears, bearings, and high-performance engine components. The vacuum environment ensures that these parts remain free of oxidation, enhancing their durability and performance.

Medical Devices

SIMUWU’s vacuum furnaces are ideal for heat treating medical devices, including implants and surgical tools. The vacuum environment is crucial for maintaining the integrity and biocompatibility of these devices.

Tooling and Molds

SIMUWU’s vacuum furnaces are used in the tooling and mold industries to ensure that components maintain their dimensional accuracy and hardness, resulting in longer tool life and more efficient production.

6. Conclusion

SIMUWU is a leading commercial vacuum furnace manufacturer, providing high-quality, energy-efficient solutions for industries requiring precise heat treatment. From vacuum heat treatment furnaces to vacuum sintering furnaces and customizable vacuum furnaces, SIMUWU offers a wide range of products designed to meet the unique needs of various industries. By choosing SIMUWU, manufacturers can achieve better results, reduce energy costs, and improve overall production efficiency.

7. Frequently Asked Questions (FAQ)

Q: What makes SIMUWU vacuum furnaces more efficient?

A: SIMUWU’s vacuum furnaces are designed with advanced insulation materials, energy recovery systems, and automated control systems that reduce energy consumption and optimize processing times.

Q: Can SIMUWU vacuum furnaces be customized for specific applications?

A: Yes, SIMUWU offers customizable vacuum furnaces that can be tailored to meet the specific temperature, pressure, and processing time requirements of different materials and industries.

Q: What industries use SIMUWU vacuum furnaces?

A: SIMUWU vacuum furnaces are used in aerospace, automotive, medical devices, tooling, and various other industries that require high precision and quality in their heat treatment processes.

Q: How do SIMUWU vacuum furnaces prevent oxidation?

A: The vacuum environment in SIMUWU’s furnaces eliminates oxygen, preventing oxidation and contamination during heat treatment processes like hardening, sintering, and brazing.

Q: How long do SIMUWU vacuum furnaces last?

A: SIMUWU’s vacuum furnaces are built with high-quality materials and are designed for long-lasting performance, offering durability and minimal downtime.