1. Introduction

Aluminum plate-fin heat exchangers are highly efficient and compact heat exchange devices. They have a complex structure, primarily composed of multiple layers of thin aluminum alloy sheets—including fins, baffles, seals, and flow guides—stacked and joined together through brazing to form a complex network of channels, thus achieving efficient heat transfer.

Vacuum brazing is the core forming process and currently the most mainstream and reliable connection method for aluminum plate-fin heat exchangers. Due to the advantages of aluminum, such as its lightweight nature, high thermal conductivity, good corrosion resistance, and ease of processing, aluminum plate-fin heat exchangers have been widely used in various fields.

In a vacuum environment, the brazing process utilizes the melting, wetting, and spreading of the brazing filler metal to achieve metallurgical bonding of the aluminum alloy components, while ensuring the airtightness, strength, and heat exchange performance of the heat exchanger.

2. Core Principle

The core principle of vacuum brazing for aluminum plate-fin heat exchangers is to achieve metallurgical bonding of multi-layer aluminum components in a high-vacuum environment, utilizing the melting point difference between the brazing filler metal and the base material, and capillary action, without the need for flux.

First, the fins, baffles, seals, and other parts are precisely stacked and placed in a vacuum furnace, which is then evacuated to a high vacuum (usually better than 5×10⁻³Pa). The temperature is then raised to a narrow temperature range above the melting point of the Al-Si brazing filler metal but below the solidus line of the base material, causing the brazing filler metal to melt. In a vacuum environment, the magnesium element in the brazing filler metal or base material evaporates at high temperatures, destroying the dense oxide film on the aluminum surface, allowing the liquid brazing filler metal to have good wettability.

Under the action of capillary force, the molten brazing filler metal fully fills the tiny gaps between the parts, undergoing interfacial diffusion and dissolution with the base material. After the holding time, controlled cooling is applied, and the brazing filler metal solidifies to form a continuous and dense brazed joint, connecting all the components into a whole, while ensuring the airtightness, structural strength, and heat exchange performance of the heat exchanger, and also avoiding corrosion problems caused by flux residue.

3. Production Process Flow

3.1 Preparation

3.1.1 Part Preparation and Cleaning:

After the fins, baffles, seals, and other parts are precisely formed, they are cleaned using alkaline washing, acid washing, and ultrasonic cleaning to remove surface oxides, oil stains, and chips. After drying, there should be no residue or fingerprints.

3.1.2 Stacking and Positioning:

Parts are stacked layer by layer according to the designed flow channels and layer structure. Special tooling fixtures are used to clamp and position the parts, controlling the assembly gap (usually controlled to 0.05~0.15mm to facilitate capillary action) to prevent misalignment and deformation during the brazing process.

3.1.3 Loading into the Furnace and Vacuum Pumping:

The workpiece is loaded onto the vacuum furnace rack, the furnace door is closed, and the vacuum pump unit is started to pump the furnace to the required vacuum level (generally better than 5×10⁻³Pa, and up to 1×10⁻⁴Pa for high-requirement products).

3.2 Segmented Heating and Holding

3.2.1 Low-Temperature Segment:

100~200℃, slow heating to fully remove moisture and residual oil from the workpiece and tooling, preventing rapid heating from causing volatile substances to boil and produce pores.

3.2.2 Medium-Temperature Segment:

300~550℃, uniform heating to ensure uniform temperature throughout the workpiece, while magnesium begins to play its role in removing the oxide film, preparing for brazing.

3.2.3 Brazing Holding Segment:

590~610℃, strict temperature control (temperature difference within ±2℃), holding for 30~60min to ensure that the brazing filler metal fully melts, wets, and fills the gaps, completing the metallurgical bonding.

3.2.4 Cooling Stage:

After the brazing holding period, the furnace cools down. The workpiece can be removed from the furnace only after cooling to around 300℃.

3.2.5 Post-Processing and Inspection:

After removal from the furnace, the tooling is removed, and visual inspection and dimensional correction are performed. Then, airtightness tests (helium leak test, hydrostatic test), tensile tests, and penetration tests are conducted to verify the joint quality.

4. Brazing Filler Metal Selection

Vacuum brazing relies on Mg to break down the aluminum oxide film. Mainstream brazing filler metals are divided into three categories.

- Al-12Si eutectic brazing filler metal has a melting point of 577℃, excellent fluidity and capillary filling properties, and good corrosion resistance. It needs to be used with Mg-containing base materials such as 5052 and 6061. The process temperature is 590~610℃, and the cost is moderate.

- Al-Si-Mg series vacuum brazing filler metals, containing 1.0~2.0% Mg, possess self-fluxing capabilities and are suitable for low-Mg base materials such as 3003 and 3004. They offer excellent wetting and high joint strength, making them the preferred choice for plate-fin products. However, attention should be paid to Mg volatilization and potential contamination of the furnace.

- Al-Si-Cu (-Mg) series high-strength brazing filler metals have a lower melting point and outstanding joint strength and high-temperature performance, but their corrosion resistance is reduced. They are only used in non-corrosive environments such as oil cooling and high-pressure applications.

In terms of form, brazing filler metal composite plates are preferred for mass production due to their uniform thickness, convenient assembly, and stable quality; brazing filler metal foil can be used for small-batch prototyping. It is also necessary to ensure a sufficient process window between the liquidus of the brazing filler metal and the solidus of the base material to avoid overheating the base material. The final grade is determined based on the medium and pressure.

5. Defects and Improvements

5.1 Unbrazed or incomplete brazing:

Caused by insufficient temperature, low vacuum, unremoved oxide film, and improper assembly gap. This can be improved by increasing the vacuum level, optimizing the holding temperature and time, strictly controlling cleaning quality, and adjusting the assembly gap.

5.2 Brazing porosity:

Caused by moisture in the workpiece, incomplete removal of volatile substances, and rapid cooling. This can be improved by extending the low-temperature degassing time, ensuring thorough drying, and optimizing the cooling rate.

5.3 Workpiece deformation and fin collapse:

Caused by excessively high temperature, uneven clamping force, and improper cooling. This can be improved by strictly controlling the maximum temperature, optimizing the tooling design, adjusting the clamping force, and ensuring uniform cooling.

5.4 Brazing filler metal loss and insufficient brazing seam:

Caused by excessive gap, excessive clamping force, and excessively high temperature. This can be improved by controlling the assembly gap, reducing the clamping force, and precisely controlling the temperature.

5.5 Base material overheating:

Caused by the temperature exceeding the solidus of the base material and local overheating. This can be improved by lowering the brazing temperature, ensuring uniform furnace temperature, and optimizing the heating curve.

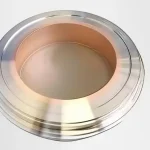

6. Why choose SIMUWU

SIMUWU vacuum aluminum brazing furnaces are equipped with a magnesium getter, which effectively stabilizes the vacuum environment, reduces MgO dust contamination of the furnace wall, lowers the outgassing rate, ensures stable high vacuum, and prevents workpiece oxidation during brazing. It protects core components, prevents magnesium vapor corrosion of heating elements and insulation screens, avoids vacuum pump/valve blockage, and reduces equipment failures and maintenance frequency. To ensure welding quality, the magnesium atmosphere concentration is controlled to avoid defects such as workpiece erosion and incomplete welds, ensuring solder wettability and weld reliability. Operating costs are reduced, maintenance procedures are simplified, spare parts replacement cycles are extended, and equipment utilization and production efficiency are improved.

The SIMUWU vacuum aluminum brazing furnace is designed with multi-zone independent temperature control, achieving a temperature uniformity of ±3℃. It can strictly follow the heating rate and holding time curves, preventing overheating and effectively improving product quality.

The key components of the SIMUWU vacuum aluminum brazing furnace use internationally renowned brands, ensuring high quality and durability. Furthermore, in case of malfunction, damaged components can be quickly identified and replaced, ensuring smooth production for the customer.

SIMUWU specializes in the manufacture of vacuum furnaces and has over ten years of relevant experience, enjoying a good reputation in the vacuum furnace manufacturing field. The product line includes vacuum gas quenching furnaces, vacuum oil quenching furnaces, and vacuum brazing furnaces, which are widely sold in developed and developing countries. Click [SIMUWU Low Temperature Vacuum Brazing Furnace] to view detailed technical information.

If you would like to learn more about vacuum furnace equipment, please send your requirements to kevin.liu@vacfurnace.com, and our company will provide you with a satisfactory solution.