1. Introduction:

Metal Powder Injection Molding (MIM) is a new powder metallurgy near-net-shape forming technology that combines modern plastic injection molding technology with powder metallurgy. The basic process involves uniformly mixing solid powder with an organic binder, granulating the mixture, and then injecting it into a mold cavity using an injection molding machine under a heated and plasticized state (~150°C) for solidification. The binder is then removed from the molded part using chemical or thermal decomposition methods, and finally, the part is sintered to achieve densification and obtain the final product.

2. Key Process Parameters

2.1 Overview:

Metal powder injection molding technology is a product of the interdisciplinary integration of plastic molding technology, polymer chemistry, powder metallurgy technology, and metal materials science. It utilizes molds to rapidly manufacture high-density, high-precision, three-dimensional complex-shaped structural parts through injection molding and sintering. It can quickly and accurately transform design ideas into products with specific structural and functional characteristics, and allows for direct mass production of parts, representing a new revolution in the manufacturing industry.

This process technology not only has the advantages of fewer process steps, no or minimal machining, and high economic efficiency compared to conventional powder metallurgy processes, but also overcomes the shortcomings of traditional powder metallurgy processes, such as uneven material properties, low mechanical properties, and difficulty in forming thin-walled and complex structural parts. It is particularly suitable for mass production of small, complex metal parts with special requirements. Process flow: Metal powder + binder → mixing → injection molding → debinding → sintering → post-treatment

2.2 Process Parameters:

Feedstock preparation: Powder particle size needs to be controlled at 5-10μm to balance fluidity and sintering activity. The binder must ensure uniform mixing; a paraffin-polypropylene system is commonly used. After granulation, the particle size should be 2-4mm for easy transport by the injection molding screw.

Injection molding: Too low a temperature can lead to insufficient filling, while too high a temperature can cause binder decomposition; the pressure needs to match the mold structure. For thin-walled parts (0.5-1mm), the injection speed needs to be increased (50-100mm/s) to avoid material shortage. Degreasing Process

Solvent Degreasing: Suitable for paraffin-based binders, highly efficient but prone to residue, requiring subsequent thermal degreasing.

Thermal Degreasing: Highly versatile, requires slow heating (1-5℃/min) to prevent cracking and deformation of the workpiece.

Catalytic Degreasing: Specifically for polyoxymethylene (POM) binders, rapid decomposition in an acidic atmosphere, suitable for complex structural parts.

Sintering Process: Using a SIMUWU vacuum furnace allows for precise control of temperature and atmosphere (Ar, H₂, or vacuum), inhibiting oxidation and promoting densification. Sintering shrinkage is 16-20%, requiring mold compensation design to ensure final dimensional accuracy.

3. Degreasing and Sintering Equipment

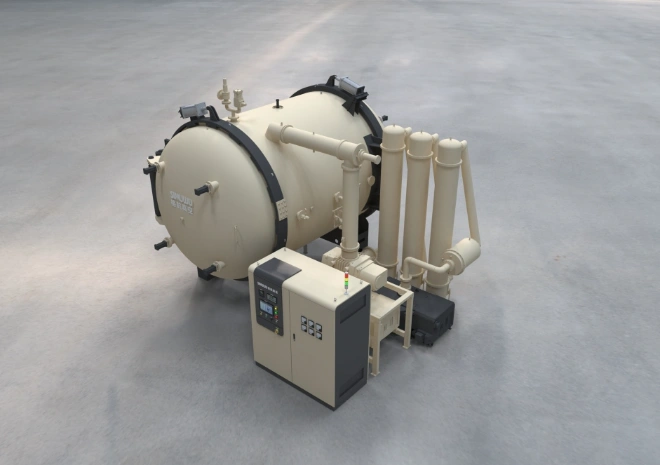

The SIMUWU horizontal vacuum degreasing (wax) sintering furnace series is primarily used for vacuum or carrier gas degreasing (wax) and sintering. It is suitable for stainless steel, cemented carbide, high-temperature alloys, high-density alloys, cermets, magnetic materials, carbides, borides, oxides, and intermetallic compounds, for vacuum or carrier gas degreasing (wax) and pre-sintering before final sintering.

This vacuum degreasing (wax) furnace adopts a horizontal water-cooled jacket structure, with a front opening door or front and rear double opening doors. Depending on the furnace temperature and customer process requirements, nickel-chromium electric heating alloy or graphite is used as the heating element and insulation screen. Other insulation materials can also be used to form a composite insulation screen. The heating element can be divided into multiple zones, each with independent temperature control and programmable PID adjustment for precise temperature control.

It is equipped with a special sealed furnace chamber and a multi-stage water-cooled butterfly-type grease trap to achieve directional airflow degreasing, ensuring no dead corners for grease accumulation in the furnace, resulting in more complete degreasing. It can be equipped with an internal or external circulating cooling device to accelerate the cooling of materials in the furnace, shorten the working cycle, and improve production efficiency.

SIMUWU’s RVS-D series vacuum dewaxing sintering furnace is an automated production equipment specifically designed for the sintering of metal and ceramic components. The sintering chamber features an optimized constant temperature field design, allowing for vacuum sintering and reactive sintering processes to be performed in a single cycle within the furnace. Depending on the application and process requirements, it can accommodate various atmospheres within the furnace, offering simple operation and precise control of furnace pressure, vacuum level, and atmosphere.

SIMUWU specializes in the manufacture of vacuum furnaces, boasting over ten years of experience and a strong reputation in the field. Our product line includes vacuum gas quenching furnaces, vacuum oil quenching furnaces, and vacuum brazing furnaces, which are widely sold in developed and developing countries. For detailed technical information, please visit:Vacuum Dewaxing & Sintering Furnace

If you would like to learn more about vacuum furnace equipment, please contact us and we will provide you with a satisfactory solution.