Material Overview

1.2344 (typically corresponding to American standard AISI H13 or Chinese standard 4Cr5MoSiV1) is a high-performance, widely used hot-work tool steel. Its key characteristic is its ability to maintain stable strength, toughness, and wear resistance at high temperatures.

Primary Applications

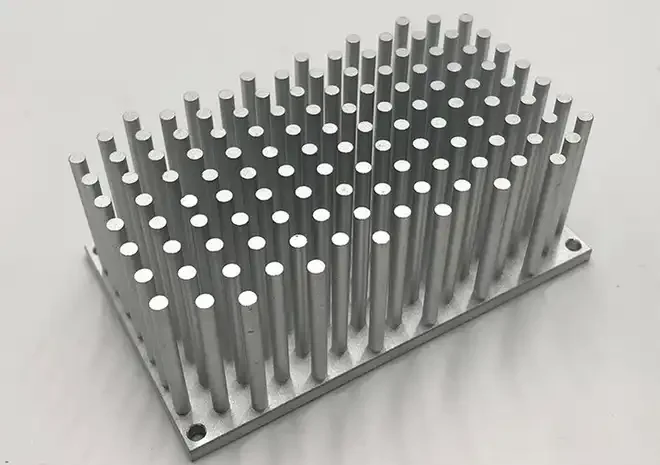

Generally, it is primarily used in the manufacture of products such as automotive engine blocks, LED heat sinks, automotive crash beams, large gears, and aerospace forgings.

Heat Treatment Performance & Process

After vacuum quenching, the theoretical hardness of 1.2344 can reach HRC 54-56.

The following is the heat treatment process for 1.2344 in a SIMUWU vacuum quenching furnace:

● Phase 1: Preheating, 550-650℃, holding for 180 minutes.

● Phase 2: Preheating, 850℃, holding for 120 minutes.

● Phase 3: Quenching heating, 1030℃, 90 minutes.

● Phase 4: Gas quenching and cooling, 6 bar nitrogen gas, 60 minutes, cooling down to approximately 80℃ before removal from the furnace.

Equipment Specifications

The following are the technical specifications of the SIMUWU vacuum quenching furnace required for vacuum quenching of material 1.2344:

| Furnace Type | Horizontal type,single chamber, internal recycle. |

| Loading method | Front Loading |

| Max. Loading size | 400×400×600 (W×H×L mm) |

| Max. Loading weight | 200 kg(including jig) |

| Power supply | 3 phase, 380V(±5%); 50Hz |

| Total power | 140kw |

| Heating power | 100kw |

| Cooling fan motor power | 110kw |

| Max.design temperature | 1300℃ |

| Working temperature | 1250℃ |

| Temperature uniformity | 9 points temp testing ±5℃ (standard AMS 2750E) |

| Temperature control accuracy | S Type thermocouple ≤±1℃ (standard AMS 2750E) |

| Quantity of heating zones | 1 zone |

| Heating element | High purity graphite |

| Heating rate(The room temperature of the empty furnace rises to 1200℃) | 0~20℃/min(Adjustable) |

| Ultimate vacuum | 6.7×10-4Pa |

| Working vacuum | 6.7 x 10-3Pa |

| Vacuum pumping speed | ≤35min(cold and empty condition to 5 Pa) |

| Pressure rising rate(cold empty furnace condition) | ≤0.67Pa/h |

| Cooling method | Air cooling/natural cooling |

| Cooling air | Nitrogen or Argon (purity: 99.99% or 99.999%) |

| Cooling rate(empty furnace 1100℃~150℃) | ≤6min |

| Max charging pressure(absolute pressure) | ≤6bar (absolute pressure-adjustable) |

| Temperature control mode | Intelligent programmable temperature controller for automatic temperature control |

| Control mode | PLC automatic / manual control interlock protection |

| Equipment color | Customized |

If you have any needs, please feel free to contact us at kevin.liu@vacfurnace.com. I will be happy to assist you.