1.Understanding the Need for Customization

Every material and production process has unique requirements. Powder metallurgy, ceramics, and hard alloy sintering often demand specific temperature profiles, controlled vacuum environments, and precise gas purging. Customization ensures that the furnace meets your exact process specifications, improving product quality and efficiency.

2.Key Parameters to Consider

Before talking to a manufacturer, define:

Production capacity (batch size, throughput)

Material requirements (metal powder type, binder removal needs)

Quality standards (density, porosity, metallurgical properties)

Budget and space limitations

3.Common Customizable Features

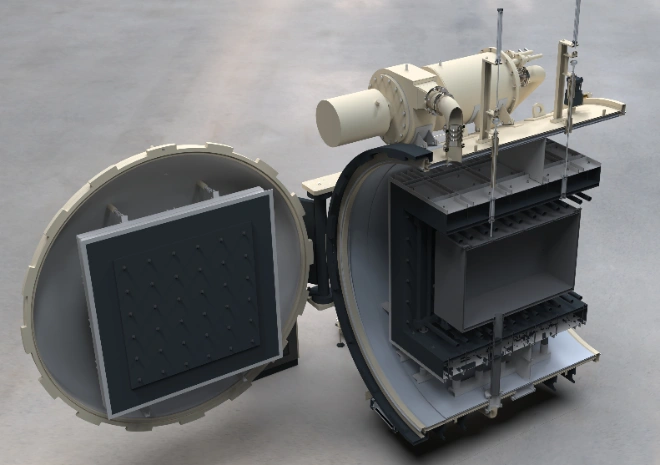

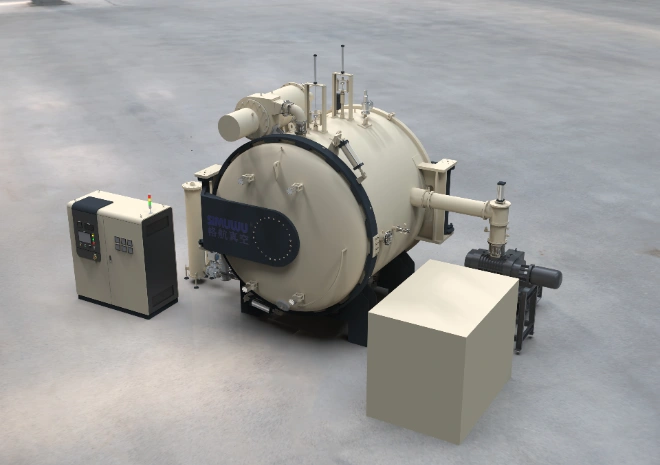

Furnace Size and Chamber Design:Choose chamber dimensions that match your product size and batch volume to maximize efficiency and reduce energy waste.

Temperature Range and Control Accuracy:Decide on maximum operating temperature (often 1200°C–1800°C) and PID control precision for stable sintering.

Atmosphere Control (Vacuum Level & Gas Types):Specify vacuum level (high, medium, or low) and process gases (argon, nitrogen, hydrogen) to achieve desired microstructure.

Loading & Automation Options:Options include manual, semi-automatic, or fully automated loading systems to streamline production.

Cooling and Quenching Systems:Select air cooling, gas quenching, or oil quenching based on hardness requirements and cycle time targets.

Control System and Software:Modern furnaces offer touch-screen PLC controls, data logging, and remote monitoring — crucial for quality audits and process optimization.

4.Practical Steps to Work with Manufacturers

Define Requirements – Make a clear list of specifications.

Consult the Supplier – Discuss feasibility, standards (CE, ISO), and lead times.

Prototype or Simulation – Request process trials if needed.

Finalize Design – Approve drawings and parameters.

Installation & Training – Ensure operators are trained.

5.Industry Use Cases for Customized Furnaces

Powder Metallurgy – Automotive gears, bearings, structural parts.

Tool Manufacturing – Carbide and ceramic tools.

Medical Devices – Titanium implants requiring precise sintering.

Aerospace – High-performance components with strict quality control.

6.Comparing Standard vs. Custom Furnaces

| Aspect | Standard Furnace | Custom Furnace |

|---|---|---|

| Cost | Lower upfront | Higher upfront |

| Lead Time | Shorter | Longer |

| Flexibility | Limited | Fully optimized |

| Process Quality | General | Tailored to application |

| Long-Term ROI | Moderate | Higher due to efficiency |

7.Benefits of Customization

Optimized cycle time

Better energy efficiency

Higher product consistency

Easier compliance with industry standards

8.Possible Challenges and Solutions

| Challenge | Solution |

|---|---|

| Higher Initial Cost | Focus on ROI and long-term savings |

| Longer Delivery Time | Plan purchase well in advance |

| Complex Design Choices | Work closely with experienced engineers |

9.Summary

Customizing a vacuum sintering furnace ensures your production line achieves maximum efficiency and quality. While it may require more investment upfront, the long-term benefits — consistent product performance, reduced operating costs, and competitive advantage — make it worthwhile.

10.Frequently Asked Questions (FAQ)

Q: When should I consider a customized furnace instead of a standard one?

A: When you have unique product dimensions, strict process control needs, or high production volume.

Q: Can I upgrade an existing furnace instead of buying a new one?

A: In some cases, yes — adding new controls, pumps, or gas systems is possible. But for major capacity changes, a new furnace is recommended.

Q: How long does it take to get a customized furnace?

A: Typically 4–8 months, depending on complexity and supplier workload.

Q: Does customization cost significantly more?

A: It usually costs more upfront but lowers long-term production costs by improving yield and efficiency.

Q: Do I need a dedicated engineering team to specify requirements?

A: Not necessarily — good suppliers will work with you to define technical parameters.

Q: Can custom furnaces be designed for Industry 4.0 integration?

A: Yes, modern furnaces support remote monitoring, data logging, and MES/ERP connectivity.