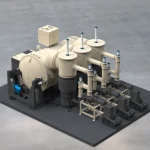

How Much Is the Vacuum Heat Treatment Furnace Price?

When companies or research institutes plan to purchase the vacuum heat treatment furnace, one of the first questions that arises is about Vacuum Heat Treatment Furnace Price. Unlike standard heating equipment, vacuum heat treatment systems involve precise engineering, strict technical requirements, and specialized components. This means Vacuum Heat Treatment Furnace Price varies greatly depending on specifications, configuration, and the intended application.

The price of a Vacuum Heat Treatment Furnace generally ranges from 50,000 US dollars to over 150,000 US dollars. The actual figure depends on the functions and specifications of the equipment — smaller systems with basic setups are usually less expensive, while larger models with advanced features fall on the higher end. Since every project is different, the most reliable way to know your exact Vacuum Heat Treatment Furnace Price is to share your requirements, and our customer service team can provide a tailored quotation if needed.

Key Factors Affecting Vacuum Heat Treatment Furnace Price

1. Maximum Operating Temperature

The higher the temperature capability, the higher the Vacuum Heat Treatment Furnace Price. A system designed for standard heat treatment processes at 1000–1200°C will generally result in a lower Vacuum Heat Treatment Furnace Price than one engineered to reach 1500–2000°C. High-temperature designs require advanced insulation materials, robust heating elements, and precise control systems.

2. Temperature Uniformity

Temperature uniformity is critical for consistent heat treatment results. Furnaces with strict uniformity tolerances (such as ±3°C) involve more advanced design, precise thermal field control, and higher material requirements. As a result, tighter temperature control will lead to a higher Vacuum Heat Treatment Furnace Price.

3. Vacuum Level

The deeper the vacuum, the higher the Vacuum Heat Treatment Furnace Price. Standard systems may operate at 10^-1 Pa, while advanced equipment can reach 10^-5 Pa or beyond. A higher vacuum level ensures better protection against oxidation and contamination, but it also requires stronger pumping systems and sealing technology, which raise Vacuum Heat Treatment Furnace Price.

4. Atmosphere Control

Some heat treatment processes require the addition of inert gases (argon, nitrogen) or special atmospheres to control chemical reactions during heating. Furnaces with built-in atmosphere control systems will inevitably increase Vacuum Heat Treatment Furnace Price compared to models without this feature.

5. Size and Loading Capacity

The larger the chamber and the higher the loading capacity, the greater the material and engineering requirements. Choosing the right size for the vacuum heat treatment furnace is essential — oversizing may lead to unnecessary investment and raise Vacuum Heat Treatment Furnace Price, while undersizing may limit production efficiency.

6. Configuration and Components

Like many pieces of industrial equipment, the choice between standard or premium components (such as pumps, sensors, controllers, and insulation) will directly influence Vacuum Heat Treatment Furnace Price. Imported parts may further raise Vacuum Heat Treatment Furnace Price but can offer advantages in reliability and lifespan.

Purchasing Guide: How to Choose Wisely

Match specifications to materials: Not every application requires extreme vacuum or ultra-high temperature. Define your material requirements first to optimize Vacuum Heat Treatment Furnace Price.

Avoid unnecessary features: Advanced functions are valuable only if they serve your process. Extra complexity can increase Vacuum Heat Treatment Furnace Price without delivering clear benefits.

Balance short-term and long-term investment: While a furnace with higher efficiency or better insulation may involve a higher initial Vacuum Heat Treatment Furnace Price, it can save energy and reduce maintenance costs in the long run.

Consult technical experts: Every process has unique needs. Engaging with specialists before purchase helps ensure the right configuration and avoids unnecessary increases in Vacuum Heat Treatment Furnace Price.

Conclusion

Vacuum Heat Treatment Furnace Price is determined by multiple factors: maximum operating temperature, vacuum level, temperature uniformity, atmosphere control, size, and component configuration. Instead of focusing only on the immediate figure, buyers should evaluate the overall performance-to-investment ratio and long-term benefits. With the right selection strategy, companies can secure the vacuum heat treatment furnace that not only fulfills current production requirements but also supports future process upgrades.