How does vacuum sintering furnace work?

1.Understanding the Role of Vacuum Sintering

Vacuum sintering is a high-precision heat treatment process used in powder metallurgy, ceramic manufacturing, and other industries that demand exact material properties. By combining high temperature with a controlled, oxygen-free atmosphere, it promotes particle bonding while minimizing defects.

2.The Science Behind Sintering

Sintering involves heating powdered material just below its melting point so that particles fuse together through diffusion. This increases density, strength, and conductivity of the final part without completely melting the material — preserving its shape.

3.Why Use a Vacuum Environment?

1. Oxygen-Free Heating

Vacuum eliminates oxygen, preventing oxidation and contamination. This is crucial for reactive metals like titanium, tungsten, or molybdenum.

2. Precise Temperature Control

Advanced PID controllers maintain stable temperatures across the furnace, ensuring uniform sintering results.

3. Controlled Atmosphere with Process Gases

In some cases, inert or reducing gases (argon, hydrogen, nitrogen) are introduced to influence microstructure or remove binders.

4. Consistent Metallurgical Results

Vacuum provides repeatability and stability, allowing manufacturers to meet strict quality standards in aerospace, automotive, and medical industries.

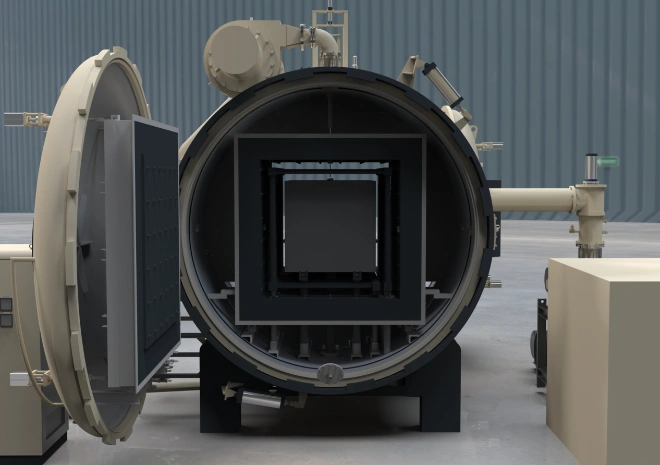

4.Step-by-Step Process Inside a Vacuum Sintering Furnace

Loading – Parts are placed on graphite trays or fixtures.

Evacuation – The chamber is pumped down to a target vacuum level.

Heating – The furnace ramps up to sintering temperature (e.g., 1200°C–1800°C).

Sintering Hold – Temperature is maintained for a set period for diffusion to occur.

Cooling – Controlled cooling under vacuum or inert gas backfill prevents oxidation and warping.

Unloading – Finished parts are removed and inspected.

5.Comparing Vacuum Sintering with Conventional Sintering

| Aspect | Conventional Sintering | Vacuum Sintering |

|---|---|---|

| Atmosphere | Air or uncontrolled | Oxygen-free |

| Contamination Risk | High | Very low |

| Product Quality | Moderate | Superior |

| Process Control | Limited | Precise |

| Cost | Lower | Higher |

6.Mechanical and Microstructural Benefits

Higher final density

Better mechanical strength

Reduced porosity

Improved corrosion resistance

7.Types of Vacuum Sintering Furnaces

Horizontal Vacuum Sintering Furnace – Easy loading, suitable for medium batches

Vertical Vacuum Sintering Furnace – Better temperature uniformity, often used for critical components

Vacuum Dewaxing & Sintering Furnace – Integrated solution for debinding and sintering in one cycle

8.Where Vacuum Sintering Excels

Vacuum sintering is ideal when:

High purity and density are required

Parts are made from reactive or refractory metals

Consistent batch-to-batch quality is critical

9.Applications in Modern Industries

Powder Metallurgy: Automotive gears, bushings, structural parts

Medical Devices: Titanium implants, surgical instruments

Aerospace: Turbine blades, heat shields

Electronics: Hard ferrites, magnetic materials

10.Advantages and Disadvantages of Vacuum Sintering

Advantages of Vacuum Sintering

Superior mechanical properties

Minimal contamination

Excellent repeatability

Compatibility with sensitive materials

Disadvantages of Vacuum Sintering

Higher equipment cost

Longer cycle time compared to basic sintering

Requires skilled operation and maintenance

11.The Bottom Line

Vacuum sintering furnaces are the gold standard for producing high-performance parts with exacting material requirements. Although they involve higher initial investment, the long-term benefits — improved quality, reduced scrap rate, and compliance with industry standards — make them a critical part of modern manufacturing.

12.Frequently Asked Questions (FAQ)

Q: What makes vacuum sintering different from conventional sintering?

A: It removes oxygen and contaminants, resulting in cleaner and stronger final products.

Q: What materials benefit the most from vacuum sintering?

A: Reactive and high-value metals like titanium, tungsten, molybdenum, and high-speed steel.

Q: How hot does a vacuum sintering furnace get?

A: Typically between 1200°C and 1800°C, depending on material requirements.

Q: Is vacuum sintering more expensive than conventional sintering?

A: Yes, but the improved quality and reduced defects often offset the higher cost.

Q: Can a vacuum sintering furnace also perform debinding?

A: Yes, with a vacuum dewaxing and sintering furnace, both steps can be combined in one cycle.

Q: How long does a typical sintering cycle take?

A: Usually between 8 and 20 hours, depending on load size and process parameters.

Q: Are vacuum sintering furnaces suitable for mass production?

A: Yes, many automotive and aerospace companies use them for high-volume production of critical components.