Vacuum nitriding is a surface-hardening technology that uses vacuum environments and nitrogen diffusion to enhance material performance.This guide explores how vacuum nitriding improves material performance, offering superior hardness and toughness compared to conventional methods.

Table of Contents

- 1. Introduction to Vacuum Nitriding

- 2. Mechanisms of Performance Enhancement

- 3. Comparative Advantages Over Conventional Nitriding

- 4. Industrial Applications and Case Studies

- 5. Limitations and Considerations

- 6. Frequently Asked Questions (FAQ)

1. Introduction to Vacuum Nitriding

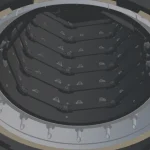

Vacuum nitriding is a surface-hardening process that combines vacuum technology with nitrogen diffusion to enhance material properties. By heating metals (e.g., steel, titanium) in a vacuum environment and introducing nitrogen-rich gases, it forms hard nitride layers on the surface without the brittleness or oxidation issues associated with conventional methods. This process is critical for applications requiring wear resistance, fatigue strength, and corrosion protection.

2. Mechanisms of Performance Enhancement

2.1 Formation of High-Hardness Nitride Layers

Vacuum nitriding produces ε-phase nitrides (e.g., Fe₂-₃N, Fe₄N) with hardness values ranging from 600–1500 HV, depending on the base material. For example, AISI 4140 steel achieves a 1200 HV surface after vacuum nitriding, compared to 800 HV via gas nitriding. The absence of oxygen in the vacuum chamber prevents oxide formation, ensuring pure nitride growth.

2.2 Reduction of Brittle “White Layers”

Conventional nitriding often creates a brittle “white layer” (amorphous Fe-N compound) prone to spalling. Vacuum nitriding minimizes this by:

Controlled nitrogen partial pressure:

Reduces excess nitrogen absorption.

Two-stage process:

Combines nitriding with post-oxidation (e.g., POSTOX®) to stabilize the surface.

Result:

A 10–30 μm compound layer with 50% higher toughness than gas-nitrided equivalents.

2.3 Controlled Diffusion for Uniformity

Vacuum environments enable precise temperature control and gas flow regulation, ensuring uniform nitrogen diffusion. This is critical for complex geometries (e.g., gears, molds), where conventional methods may cause uneven hardening. Studies show vacuum nitriding reduces hardness variation across a part from ±15% (conventional) to ±5%.

3. Comparative Advantages Over Conventional Nitriding

| Parameter | Vacuum Nitriding | Conventional Gas Nitriding |

|---|---|---|

| Surface Hardness (HV) | 600–1500 | 500–1000 |

| White Layer Thickness | <10 μm (eliminated in POSTOX) | 20–50 μm |

| Process Time | 20–40 hours | 40–80 hours |

| Environmental Impact | Zero emissions | Releases ammonia/NOx |

Case Study:

Automotive gears vacuum-nitrided at 530℃ for 24 hours exhibited 40% longer wear life and 30% lower friction compared to gas-nitrided gears.

4. Industrial Applications and Case Studies

4.1 Automotive Components

Gear Shafts:

Vacuum nitriding increases surface hardness to 1100 HV, reducing wear rates by 50% in high-load transmissions.

Engine Valves:

Nitrided layers (800 HV) resist corrosion from combustion gases, doubling service life.

4.2 Aerospace Alloys

Titanium 6Al-4V:

Vacuum nitriding forms TiN layers (2000 HV) for turbine blades, improving erosion resistance at 600℃.

Nickel-Based Superalloys:

Nitrided surfaces withstand 1000℃ without oxidation, critical for jet engine components.

4.3 Tooling and Dies

Vacuum nitriding reduces sticking and wear, enabling 3× longer production runs for plastic injection molding.

Cold Work Tool Steel:

Nitrided layers (1200 HV) resist galling in stamping operations.

If you’d like to explore more application scenarios, please click here.

5. Limitations and Considerations

Material Sensitivity:

Not suitable for low-alloy steels prone to “nitriding embrittlement.”

Cost:

Equipment and process costs are 20–30% higher than gas nitriding.

Batch Size:

Limited by vacuum chamber capacity (typically <1 ton per cycle).

6. Frequently Asked Questions (FAQ)

Q: What distinguishes vacuum nitriding from conventional gas nitriding?

A: Vacuum nitriding eliminates oxidation, reduces brittle white layers, and achieves higher surface hardness (600–1500 HV vs. 500–1000 HV) with greater uniformity.

Q: Which industries benefit most from vacuum nitriding?

A: Automotive (gears, valves), aerospace (turbine blades), and tooling (molds, dies) due to improved wear, fatigue, and corrosion resistance.

Q: Why does vacuum nitriding produce tougher surfaces?

A: Controlled nitrogen diffusion and POSTOX treatments minimize brittle ε-phase accumulation, resulting in compound layers with 50% higher toughness.

Q: Can vacuum nitriding be applied to titanium alloys?

A: Yes, it forms hard TiN layers (2000 HV) ideal for aerospace components exposed to high temperatures and erosion.

Q: What are the environmental advantages of vacuum nitriding?

A: It eliminates harmful emissions (ammonia, NOx) associated with gas nitriding, making it compliant with strict environmental regulations.

Q: How does process time compare between vacuum and gas nitriding?

A: Vacuum nitriding is 2× faster (20–40 hours vs. 40–80 hours) due to efficient nitrogen diffusion in a vacuum.

Q: What is the typical thickness of nitride layers formed?

A: 10–30 μm for compound layers and 200–500 μm for total diffusion zones, depending on material and process parameters.

For more insights, feel free to browse our specific products, such as the Vacuum Nitriding Furnace or Vertical Structure PlT Type Gas Nitriding Furnace.