1. What is high temperature vacuum brazing furnace?

Vacuum brazing furnace is a special device that heats metals in a high vacuum environment to connect them firmly without oxidation through molten brazing material.It allows metals to be bonded without oxidation, producing strong, precise, and clean joints. This technology is widely applied in aerospace, electronics, and high-precision engineering industries.

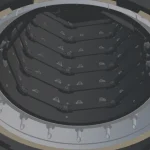

2. Structure of a High Temperature Vacuum Brazing Furnace

Furnace Chamber: Where components are placed and heated uniformly.

Vacuum System: Pumps and valves create and maintain high-vacuum conditions.

Heating System: Can include resistance heating, induction heating, or gas heating for accurate temperature control.

Control System: Monitors temperature, vacuum levels, and process parameters.

Cooling System: Ensures controlled cooling to preserve material properties after brazing.

3. Principles and Steps of Vacuum Brazing

Component Preparation: Clean and assemble parts with appropriate brazing filler.

Vacuum Creation: Evacuate air and moisture from the furnace chamber.

Heating: Raise temperature to melt the filler without affecting base metals.

Brazing Process: Molten filler flows into joints by capillary action, forming strong bonds.

Cooling: Parts are cooled under vacuum to prevent oxidation and maintain joint integrity.

4. Role of the Vacuum Environment

Prevents oxidation and contamination of metal surfaces.

Improves the flow and wettability of brazing filler.

Ensures uniform, high-quality brazed joints.

5. Advantages and Applications

Advantages:

Strong and corrosion-resistant joints

High dimensional accuracy

Suitable for complex or high-value components

Applications:

Aerospace engine components

Electronic devices

Precision machinery

Heat exchangers and tooling

6. FAQ

Q: Can vacuum brazing join dissimilar metals?

A: Yes, it allows metals with different melting points to be joined reliably.

Q: What temperature range is typical for high temperature vacuum brazing?

A: Typically between 700°C and 1200°C, depending on materials.

Q: How long does a typical brazing cycle take?

A: It can range from a few hours up to 10 hours, depending on part size and material.

Q: Is special surface preparation required?

A: Yes, cleaning and proper handling are essential for strong, oxidation-free joints.