Detailed Explanation of Vacuum Heat Treatment Technology and the Key Role of Vacuum Furnaces

1.What is Vacuum Heat Treatment?

Vacuum heat treatment technology combines vacuum and heat treatment technologies. It is an engineering technique that can modify the properties of metal materials or mechanical parts, thereby enhancing their practical value.

2.What are the characteristics of materials after vacuum heat treatment?

Metal materials or mechanical parts that have undergone vacuum heat treatment exhibit characteristics such as no oxidation or decarburization, minimal deformation, excellent surface quality, long service life, zero pollution, no environmental hazards, and superior mechanical properties.

3.What industries are vacuum heat treatments used in?

Vacuum heat treatment is an indispensable key technology in modern manufacturing and is widely used in industries such as machinery, metallurgy, energy, transportation, weapons, construction, light industry, textiles, chemicals, petroleum, aerospace, and electronics.

4.Classification of Vacuum Heat Treatment

There are many types of vacuum heat treatment. Depending on the performance requirements of the heat-treated material or part, vacuum heat treatment processes include vacuum annealing, vacuum tempering, vacuum normalizing, vacuum quenching, vacuum carburizing, vacuum nitriding, vacuum sintering, vacuum brazing, and vacuum surface treatment.

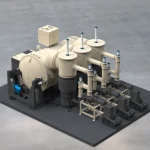

5.The Role of Vacuum Furnaces

Vacuum furnaces provide a controlled vacuum environment for vacuum heat treatment of metal materials, preventing oxidation and decarburization during the heating process, ensuring minimal deformation, maintaining surface quality, and stabilizing mechanical properties.

Vacuum furnaces can also perform processes such as vacuum annealing, vacuum quenching, vacuum carburizing, vacuum nitriding, vacuum sintering, and vacuum brazing, supporting a wide range of industrial applications. Their clean, pollution-free, and precise heat treatment capabilities make them an indispensable key piece of equipment in modern manufacturing, from aerospace and automotive to energy, electronics, and advanced machinery.

Using vacuum furnaces not only improves product reliability and extends component life, but also meets high-performance industry technical requirements.