1. Introduction

The Importance of Precision in Aerospace Manufacturing

Aerospace components must meet strict performance, safety, and reliability standards due to the extreme conditions they endure, such as high temperatures, mechanical stress, and corrosive environments. High-precision manufacturing processes are crucial in producing these components with the exact material properties required for optimal performance.

Role of Vacuum Furnaces in Aerospace

Vacuum furnaces are indispensable tools in aerospace manufacturing, used for heat treatment, sintering, brazing, and joining of high-performance materials. These furnaces create a controlled environment that eliminates oxidation and contamination, which is essential for ensuring the quality and longevity of aerospace components.

2. Understanding Vacuum Furnace Technology

What is a Vacuum Furnace?

A vacuum furnace is a specialized furnace used to heat materials in a vacuum or controlled atmosphere. It provides precise temperature control and ensures that materials, such as titanium, superalloys, and metal powders, are processed without exposure to oxygen, preventing oxidation and contamination.

How Vacuum Furnaces Work in Aerospace

Vacuum furnaces operate by creating a low-pressure or vacuum environment inside a chamber. This controlled atmosphere allows for processes like heat treatment, sintering, and brazing, ensuring that the materials retain their integrity and perform well in demanding aerospace applications.

3. Why Vacuum Furnaces Are Essential in Aerospace

Benefits of Vacuum Furnace Technology in Aerospace

Vacuum furnaces offer several benefits in aerospace applications, such as preventing oxidation of sensitive materials, improving material strength and fatigue resistance, and ensuring that components meet stringent performance requirements.

Key Materials Processed with Vacuum Furnaces

Materials like titanium alloys, nickel-based superalloys (e.g., Inconel), and various aerospace-grade metal powders are processed in vacuum furnaces. These materials are critical for high-performance components like turbine blades, engine parts, and structural elements.

4. Key Applications of Vacuum Furnaces in Aerospace

Heat Treatment of Aerospace Alloys (Titanium, Superalloys)

Titanium and nickel-based superalloys are frequently used in aerospace due to their high strength-to-weight ratios and resistance to extreme temperatures. Vacuum furnaces are used to heat treat these materials to achieve the desired microstructure and enhance mechanical properties.

Vacuum Brazing and Joining Aerospace Components

Vacuum brazing is a crucial process for joining aerospace components, such as turbine blades, where precise and strong joints are necessary for performance and safety. The vacuum environment ensures that the brazing process occurs without contamination.

Sintering and Powder Metallurgy

Vacuum furnaces are also used for sintering metal powders in the production of high-precision aerospace components. Sintering under vacuum prevents oxidation and ensures that the resulting components have high density, strength, and resistance to wear.

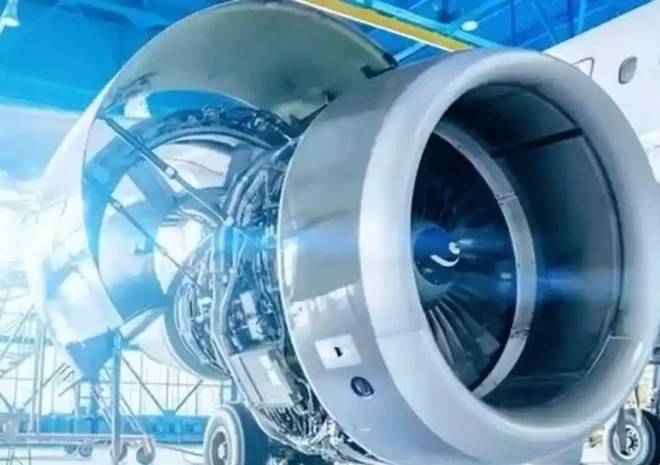

Manufacturing of Turbine Blades and Engine Parts

Vacuum furnaces are essential in the manufacturing of turbine blades and other engine components. These parts require precise heat treatment to ensure they can withstand the extreme temperatures and stresses experienced during flight.

5. Advantages of Using Vacuum Furnaces in Aerospace

Enhanced Material Properties

By providing controlled processing conditions, vacuum furnaces improve the material properties of aerospace components, such as tensile strength, fatigue resistance, and thermal stability.

Precision and Control

Vacuum furnaces offer precise temperature control and uniform heating, which is crucial for achieving consistent and high-quality results in aerospace manufacturing.

Longer Component Lifespan

The high-quality processing provided by vacuum furnaces ensures that aerospace components, such as turbine blades and engine parts, have a longer operational life, reducing maintenance costs and improving overall reliability.

6. Challenges in Using Vacuum Furnaces in Aerospace

High Initial and Operational Costs

Vacuum furnaces are expensive to purchase and operate. The energy required to maintain high temperatures in a vacuum can result in significant operational costs, which can make them a costly investment for aerospace manufacturers.

Energy Consumption

Due to the high temperatures and controlled environments required for aerospace processes, vacuum furnaces can consume a considerable amount of energy, which can impact production costs.

Scaling Production Challenges

While vacuum furnaces are ideal for producing high-performance aerospace components, scaling up production for mass manufacturing can be challenging due to the complexity and cost involved in maintaining the required conditions.

7. Future Trends in Vacuum Furnace Technology for Aerospace

Advances in Furnace Design

Future advancements in vacuum furnace technology will focus on improving energy efficiency, increasing throughput, and integrating automation for better precision and reduced human error.

Automation and Smart Monitoring

The integration of smart sensors and automation into vacuum furnaces will enhance process control and enable real-time monitoring, leading to improved consistency and reduced downtime in aerospace manufacturing.

8. Summary

Vacuum furnaces play a critical role in the aerospace industry, enabling precise heat treatment, sintering, and brazing of high-performance materials. While challenges such as high costs and energy consumption exist, the advantages—such as enhanced material properties, precision control, and longer component lifespans—make vacuum furnaces indispensable for aerospace manufacturing. As the industry evolves, innovations in furnace design and automation will continue to improve the efficiency and cost-effectiveness of these essential tools.