Titanium plates are primarily used in fields with extremely high demands on material properties, such as biomedicine, aerospace, chemical engineering, and energy sectors. They leverage the excellent biocompatibility, superior corrosion resistance, high strength, and lightweight characteristics of titanium and its alloys.

The vacuum sintering process effectively controls material purity, porosity, and microstructure, proving particularly crucial for preparing porous titanium coatings. It ensures high-temperature treatment occurs in an oxygen-free or inert gas environment, yielding titanium plates or coatings with superior performance.

The vacuum sintering process for titanium plates follows these steps:

Temperature: Ambient ~ Max 1,050°C,2-3 stage ramp-up (1-2 hours dwell time per stage);

Cooling:Natural cooling (furnace cooling) after reaching or maintaining peak temperature

Ramp rate: 3°C/min

Vacuum: 5×10⁻⁵ Torr maintained (until furnace cooling)

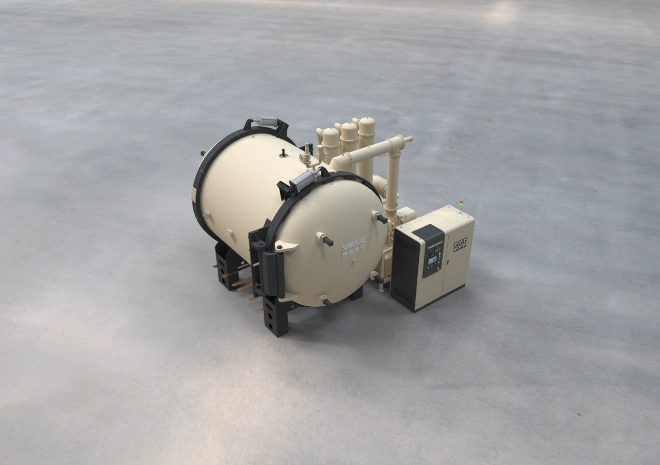

The following are the technical parameters for the vacuum sintering furnace used in the vacuum sintering of titanium sheet:

| Furnace type | Horizontal type,single chamber, internal recycle |

| Loading method | Front Loading |

| Effective working zone | 850×800×1200(W×H×L mm) |

| Max. loading weight | 1000 kg(Including jig) |

| Power supply | 3 Phase 380V(±5% );60Hz |

| Total power | 275kw |

| Heating power | 240kw |

| Cooling fan motor power | 37kw |

| Max.design temperature | 1250℃ |

| Max.working temperature | 1200℃ |

| Temperature uniformity(Vacuum、Empty Furnace、500-1000℃) | 9 points temp testing (±5℃) (standard AMS 2750F) |

| Temperature control accuracy | R-type thermocouple ≤ ± 1℃ |

| Temperature control instrument accuracy | ≤0.1 ℃ |

| Quantity of heating zones | 3-Zone independent temperature control |

| Heating element | High-temperature molybdenum |

| Heating rate (From the room temperature of the empty furnace rises to 1200℃) | 0~17 ℃/min(Adjustable) |

| Ultimate vacuum (Empty furnace, cold state, after drying and degassing) | 5×10–6 Torr |

| Working vacuum(Empty furnace,room temperature) | 5×10–5 Torr |

| Evacuation time (after diffusion pump preheating, with an empty and cold furnace, to the working vacuum ) | ≤40 min |

| Pressure rise rate (empty furnace, cold state) | ≤0.67 Pa/h |

| Cooling method | Air cooling/Natural cooling |

| Cooling gas | Nitrogen or Argon (purity:99.99% or 99.999%) |

| Max charging pressure(absolute pressure and adjustable) | <2 bar |

| Temperature control mode | Intelligent programmable temperature controller for automatic temperature control |

| Control mode | PLC automatic / manual control interlock protection |

| Equipment color | Customized |

If you have any needs or inquiries, please feel free to contact us at furnace@vacfurnace.com. We look forward to serving you