1.Core Properties of Silicon Carbide Material

As a high-performance inorganic non-metallic material, silicon carbide occupies an important position in several key fields due to its outstanding comprehensive properties. Its core properties include:

Ultra-high Hardness and Wear Resistance: With a Mohs hardness of up to 9.5, second only to diamond, it can withstand wear under harsh working conditions and is suitable for manufacturing wear-resistant components;

Excellent Corrosion Resistance: It has strong resistance to corrosive media such as acids, alkalis, and salts, and is widely used in the field of chemical anti-corrosion equipment;

Extremely High Melting Point and Thermal Stability: Its melting point exceeds 2700°C, and it maintains stable physical and chemical properties even in high-temperature environments, making it a core raw material in the refractory material field;

Outstanding Semiconductor Properties: It possesses good electrical performance, and its adjustable resistivity enables broad application prospects in fields such as power semiconductors and electronic components.

Based on the above properties, silicon carbide is currently widely used in high-end fields such as refractory materials, semiconductor devices, medical equipment, and aerospace, serving as a key material for promoting the upgrading of related industries.

2.Core Advantages of Vacuum Sintering Furnace in Silicon Carbide Sintering

In the silicon carbide sintering process, compared with traditional sintering equipment, the vacuum sintering furnace fundamentally solves the problems of sintering quality and efficiency, with its core advantages reflected in the following four aspects:

Ensuring Product Purity and Avoiding Oxidation Reactions: The vacuum environment can effectively isolate oxygen in the air, completely preventing silicon carbide from undergoing oxidation reactions with oxygen during high-temperature sintering, thus ensuring the chemical purity of silicon carbide products from the source and avoiding performance degradation caused by oxidation;

Efficiently Removing Impurities and Improving Product Cleanliness: The vacuum environment can accelerate the volatilization of impurity components in the binder of the sintered green body, and at the same time, expel trace impurity gases remaining inside the green body, significantly reducing the impurity content in the product and further improving the cleanliness and performance stability of silicon carbide products;

Reducing Internal Porosity and Enhancing Product Density: Under the synergistic effect of vacuum and high temperature, the pores inside the green body will continuously shrink due to gas discharge, effectively reducing the number and size of internal pores, greatly improving the density of silicon carbide products, and thereby enhancing their mechanical strength, wear resistance, and corrosion resistance;

Ensuring Uniform Heating and Improving Production Consistency: The vacuum sintering furnace has excellent furnace temperature uniformity, enabling uniform heating of all parts of the silicon carbide green bodies in batch sintering, avoiding product performance fluctuations caused by local temperature differences, ensuring the quality consistency of batch products, and at the same time improving overall production efficiency to meet the needs of large-scale production.

3. Key Parameters and Configuration Selection of Special Vacuum Furnace for Silicon Carbide Sintering

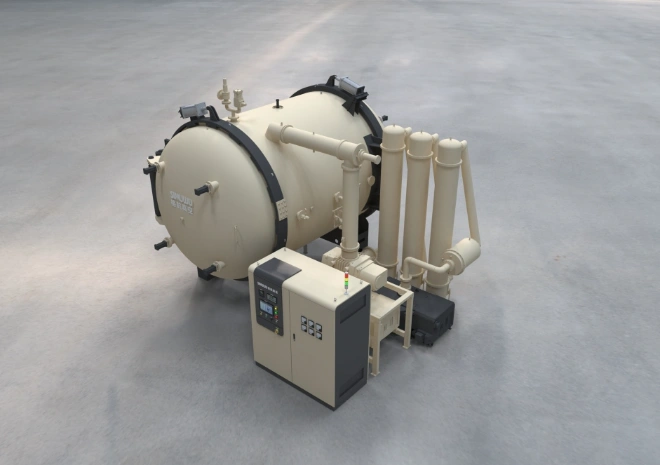

In response to the special process requirements of silicon carbide sintering, the special vacuum sintering furnace must meet strict requirements in terms of temperature, vacuum degree, structural design, and control system.SIMUWU vacuum furnace configurations and parameters are as follows:

3.1Core Performance Parameters

Maximum Sintering Temperature: It should reach 2400°C to meet the high-temperature conditions required for full sintering of silicon carbide and ensure complete densification of the green body;

Furnace Temperature Uniformity: The control accuracy is ±5°C, ensuring uniform heating of the green bodies in the same batch and avoiding product quality impacts caused by temperature deviations;

Vacuum Degree: The ultimate vacuum degree can reach 6.7×10⁻¹Pa, providing a reliable vacuum environment for impurity removal and oxidation prevention to meet the sintering needs of high-purity silicon carbide.

3.2 Key Structural Design

Heating Chamber Design: A circular heating chamber structure is adopted, which utilizes the symmetry of the circular space to achieve uniform heat distribution and further improve furnace temperature uniformity; at the same time, a graphite material box is equipped, which can effectively isolate the waste gas generated by the workpiece during high-temperature sintering, prevent the waste gas from corroding or contaminating the heating elements, prolong the service life of the equipment, and ensure stable sintering process;

Debinding System: It integrates efficient degreasing (debinding) function, eliminating the need for additional independent degreasing equipment. This not only simplifies the production process but also reduces equipment investment costs and improves production efficiency;

Furnace Shell Structure: A double-layer water-cooled jacket design is adopted, which can efficiently dissipate excess heat generated by the furnace body during operation, maintain stable furnace body temperature, and avoid equipment damage caused by local overheating; meanwhile, the furnace shell is equipped with a dedicated sewage discharge device, which can regularly clean impurities in the cooling water, ensure long-term stable operation of the cooling water system, and reduce the risk of equipment failure.

3.3High-Precision Control System

Temperature Control Core: The Eurotherm Model 2604 temperature controller is adopted, with a control accuracy of up to ±0.1% F.S (Full Scale), which can accurately match the complex temperature curve requirements of silicon carbide sintering and assist in process optimization and upgrading; this controller has powerful communication and expansion functions, supporting the setting of no less than 888 temperature/time segments, and can realize functions such as intelligent PID adjustment and automatic switching of heating control channels to meet the needs of diverse sintering processes; at the same time, it has a built-in thermocouple open-circuit fault redundancy function, which can quickly locate faults, simplify the troubleshooting process, and greatly improve the reliability of the equipment during production;

Low-Voltage Component Configuration: All low-voltage components are selected from internationally renowned brands such as Siemens, Schneider, and Phoenix. These components have significant advantages in terms of quality, performance stability, and manufacturing craftsmanship, which can greatly reduce the failure rate of the control system; meanwhile, the high standardization of well-known brand components enables users to quickly select and replace faulty components in case of failures in the later stage, minimizing production losses caused by equipment failures.

For detailed product specifications, please refer to the [SiC Vacuum Sintering Furnace] or contact us.