1. Overview

40Cr is one of the most commonly used alloy structural steels in the Chinese GB standard. Its greatest characteristic is its excellent balance: it is inexpensive, possesses comprehensive mechanical properties (balanced strength, toughness, and wear resistance), and has a very mature heat treatment process. In the industry, it is often referred to as the “king of quenched and tempered steel,” and it can be found in almost all mechanical parts that need to bear medium loads. Specific application scenarios can be divided into the following categories: shafts; gears; high-strength bolts; pins and bushings; mold frames/bases; molds, etc.

2. Advantages of Vacuum Quenching for 40Cr

Vacuum quenching enables 40Cr parts to achieve excellent surface brightness without oxidation or decarburization. While maintaining the required mechanical properties after heat treatment, the uniform high-pressure nitrogen cooling significantly reduces quenching deformation, thus eliminating subsequent cleaning and tedious fine grinding processes. This makes it the optimal process choice for achieving “near-net-shape” manufacturing of precision 40Cr structural components.

3. 40Cr Vacuum Quenching Process Parameters

The following is a detailed process flow for vacuum quenching of 40Cr:

- 1. Preheating, 550-650℃, Time: 30-60 minutes

- 2. Heating, 750-800℃, Time: 30-45 minutes

- 3. Soaking, 840-860℃, Time: 30-60 minutes

- 4. Air cooling, reducing the workpiece temperature to below 200℃ within 4-6 minutes.

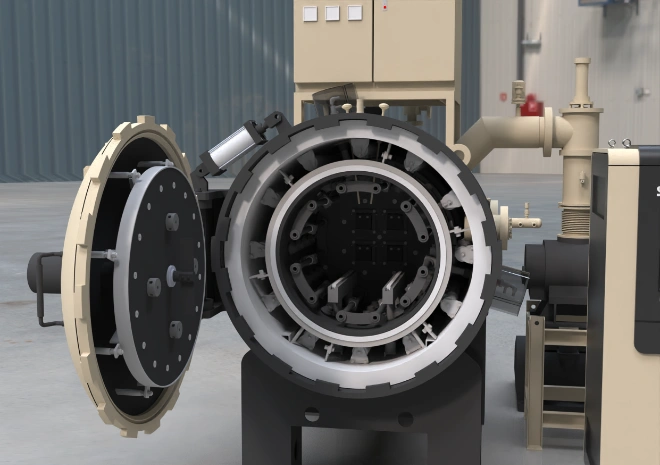

4. Technical Specifications of SIMUWU Vacuum Quenching Furnace

The following are the technical parameters of the SIMUWU vacuum quenching furnace required for vacuum quenching of 40Cr steel:

| Furnace Type | Horizontal type,single chamber, internal recycle. |

| Loading method | Front Loading |

| Max. Loading size | 400×400×600 (W×H×L mm) |

| Max. Loading weight | 200 kg(including jig) |

| Power supply | 3 phase, 380V(±5%); 50Hz |

| Total power | 140kw |

| Heating power | 100kw |

| Cooling fan motor power | 110kw |

| Max.design temperature | 1300℃ |

| Working temperature | 1250℃ |

| Temperature uniformity | 9 points temp testing ±5℃ (standard AMS 2750E) |

| Temperature control accuracy | S Type thermocouple ≤±1℃ (standard AMS 2750E) |

| Quantity of heating zones | 1 zone |

| Heating element | High purity graphite |

| Heating rate(The room temperature of the empty furnace rises to 1200℃) | 0~20℃/min(Adjustable) |

| Ultimate vacuum | 6.7×10-4Pa |

| Working vacuum | 6.7 x 10-3Pa |

| Vacuum pumping speed | ≤35min(cold and empty condition to 5 Pa) |

| Pressure rising rate(cold empty furnace condition) | ≤0.67Pa/h |

| Cooling method | Air cooling/natural cooling |

| Cooling air | Nitrogen or Argon (purity: 99.99% or 99.999%) |

| Cooling rate(empty furnace 1100℃~150℃) | ≤6min |

| Max charging pressure(absolute pressure) | ≤6bar (absolute pressure-adjustable) |

| Temperature control mode | Intelligent programmable temperature controller for automatic temperature control |

| Control mode | PLC automatic / manual control interlock protection |

If any request, please feel free to contact us. SIMUWU will be at your service.