Application of vacuum quenching furnace in M2 high-speed steel

M2 high-speed steel is a widely used general-purpose high-speed tool steel, belonging to the molybdenum-type high-speed steel family.

High Hardness: After heat treatment, it can achieve a very high hardness.

High Wear Resistance: Containing high levels of alloying elements such as carbon, molybdenum, tungsten, and vanadium, it possesses excellent wear resistance.

Excellent Red Hardness: This is one of the most important characteristics of high-speed steel. “Red hardness” refers to the ability to maintain high hardness and cutting performance even when subjected to high temperaturesduring high-speed cutting. M2 excels in this aspect.

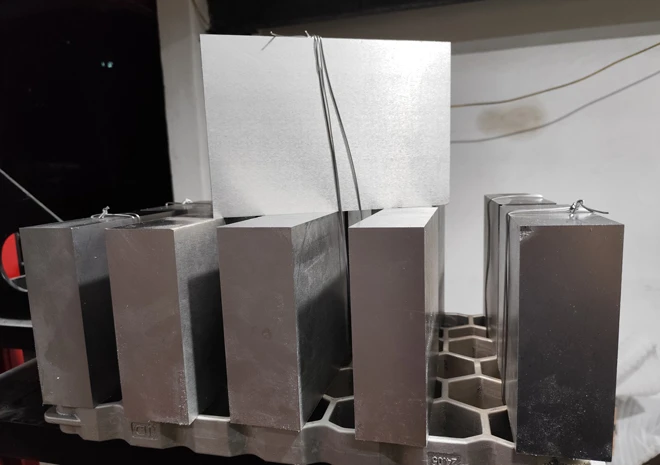

The following is the process flow for vacuum quenching and vacuum tempering required to obtain M2 high-speed steel:

1.Preheating Stage

First Preheating: Temperature controlled between 550°C and 650°C, holding time approximately 10 to 20 minutes after furnace through-heating.

Second Preheating: Temperature raised to between 850°C and 900°C, holding time approximately 10 to 20 minutes after furnace through-heating.

2.Austenitizing and Gas Quenching

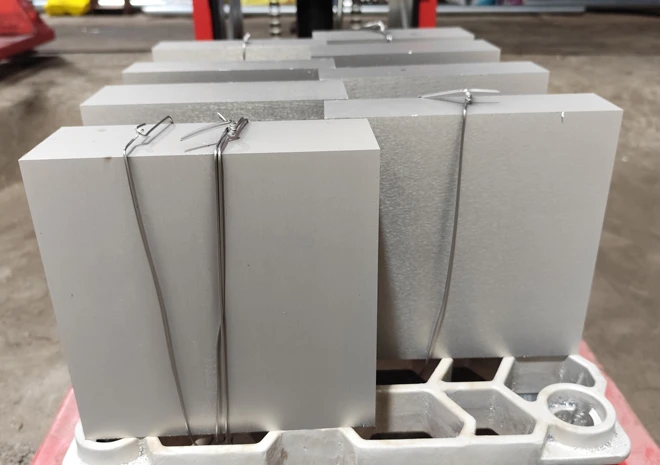

Quenching Heating: The temperature is rapidly raised to the austenitizing temperature, ranging from 1180°C to 1230°C. Holding time is determined based on workpiece size, typically 2 to 10 minutes.

High-Pressure Gas Quenching: High-purity nitrogen or helium is used as the cooling medium, with pressure typically between 0.5 MPa and 1.0 MPa or higher. Cooling must continue until the workpiece temperature drops below 50°C to ensure complete martensite transformation.

3.Multiple Tempering Stages

To eliminate brittleness, transform retained austenite, and achieve secondary hardening, multiple high-temperature tempering stages are necessary:

Tempering Temperature: The optimal temperature range is 540°C to 570°C.

Holding Time: Each tempering stage requires holding at that temperature for 1 hour or longer to ensure complete heat penetration.

Number of Tempering Stages: M2 high-speed steel requires at least 2 tempering stages, typically.

Cooling Requirements: Crucially, the workpiece must be completely cooled to room temperature after each tempering stage. This is essential for ensuring retained austenite transformation and achieving the final high hardness.

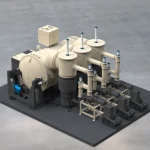

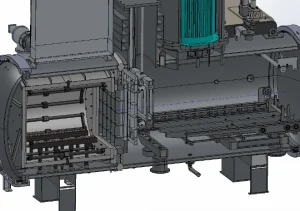

The following are the specific parameters of the vacuum quenching furnace required for vacuum quenching and tempering of high-speed steel M2:

| Furnace type | Horizontal type,single chamber, internal recycle |

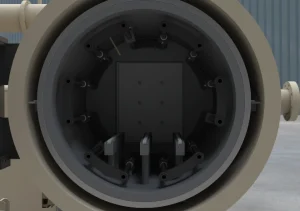

| Loading method | Front Loading |

| Max. Loading size | 500×500×700(W×H×L mm) |

| Max. Loading weight | 400kg (including jig) |

| Power supply | 3 phase, 380V(±5%); 50Hz |

| Total power | 170kw |

| Heating power | 140kw |

| Cooling fan motor power | 132kw |

| Max.design temperature | 1300℃ |

| Working temperature | 1250℃ |

| Temperature uniformity | 9 points temp testing (±5℃) (standard AMS 2750F) |

| Temperature control accuracy | S Type thermocouple ≤ ±1℃ |

| Quantity of heating zones | 1 zone |

| Heating element | High-purity graphite |

| Heating rate(The room temperature of the empty furnace rises to 1100℃) | 0~20℃/min(Adjustable) |

| Ultimate vacuum(Empty furnace, cold state, after drying and degassing) | 7×10-3pa |

| Working vacuum(Empty furnace,room temperature) | 5×10-2pa |

| Time to reach working vacuum(Empty furnace, cold state, clean condition; from atmospheric pressure to working vacuum) | ≤70min(including diffusion pump heating time) |

| Pressure rise rate (empty furnace, cold state) | ≤0.67Pa/h |

| Cooling method | Air cooling/natural cooling |

| Cooling air | Nitrogen or Argon (purity: 99.99% or 99.999%) |

| Cooling rate (empty furnace, 1100°C~200°C) | ≤ 40-300℃/min |

| Max charging pressure(absolute pressure and adjustable) | <6 bar |

| Temperature control mode | Intelligent programmable temperature controller for automatic temperature control |

| Control mode | PLC automatic / manual control interlock protection |

| Equipment color | Customized |

If you have any needs, please feel free to contact us at kevin.liu@vacfurnace.com or WA +86-21-5087-8190. I will be happy to assist you.