1. Properties and Applications of 1.2379 Tool Steel

1.2379 is a high-carbon, high-chromium cold-work tool steel that is widely used in industry. It possesses extremely high wear resistance, excellent dimensional stability, high hardness, good toughness, and moderate corrosion resistance. This metal is primarily used in the manufacture of cold-working tools that require resistance to significant wear and have complex shapes, such as: metal stamping dies, cutting tools, knives/hand tools, and forming tools.

2. 1.2379 Steel Oil Quenching Process

To obtain high-strength metal like 1.2379, vacuum oil quenching is an essential step. The following is the specific process for vacuum oil quenching of 1.2379:

- 1. First stage preheating: Preheat and hold at a temperature of 600-650℃ for 45-60 minutes.

- 2. Second stage preheating: After heating, hold at a temperature of 800-850℃ for 45-60 minutes.

- 3. Heating and austenitizing: Heat and hold at a temperature of 1020-1040℃ for 20-45 minutes.

- 4. Quenching and cooling: Oil temperature: 40-80℃, oil exit temperature: 150-200℃.

- 5. Multiple tempering treatments are required to relieve stress and stabilize the microstructure.

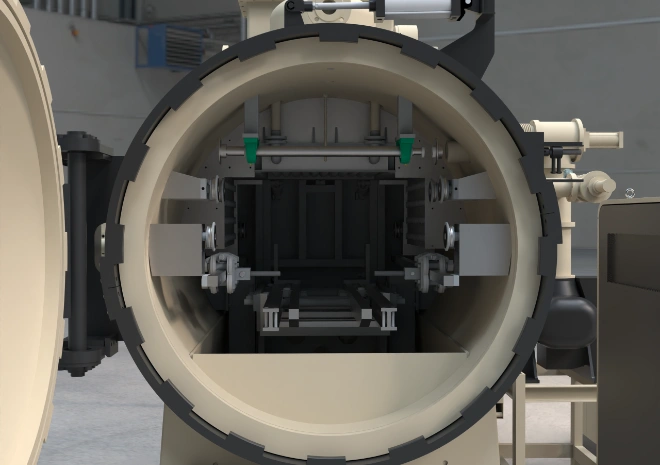

3. Technical Parameters of SIMUWU Dual-Chamber Furnace

In 1.2379 steel vacuum oil quenching process, SIMUWU’s vacuum oil quenching furnace can complete the entire process flawlessly through automatic program control. The following are the technical parameters required for the vacuum oil quenching furnace:

| Furnace type | Horizontal, dual chamber, double door |

| Loading method | Front loading |

| Uniformity size | 900×600×600(L×W×H mm) |

| Max loading weight | 600kg(including jig) |

| Power supply | 3 phase, 380v(±5%),50Hz |

| Heating power | 180kw |

| Motor power | 18.5kw |

| Max design temperature | 1320℃ |

| Working temperature | 500-1050℃ |

| Temperature uniformity | 9 points temperature measurement(±5℃) |

| Temperature control accuracy | S type thermocouple ±1℃(Standard AMS2750E) |

| Quantity of heating zone | 1 zone independently temperature control |

| Heating element | High purity graphite |

| Time of workpiece transform(s) | 25(From heating chamber to cooling chamber) |

| Time to working temperature | ≤60min |

| Empty furnace temperature rising rate | 0~25℃ /min(speed adjustable) |

| Ultimate vacuum | 4×10-1pa(cold empty furnace, after fully drying) |

| Working vacuum | 5.0 x 100pa |

| Time to working vacuum | ≤40min(empty furnace and cold condition) |

| Pressure rising rate | ≤0.67Pa/h(empty furnace and cold condition) |

| Cooling method | Air cooling/ natural cooling |

| Cooling gas | Nitrogen or Argon(purity: 99.99% or 99.999%) |

| Cooling rate(empty furnace 1200℃~150℃) | ≤45mins |

| Quenching gas charging pressure | < 2 bar (absolute pressure) |

| Cooling water consumption | ≤ 20 cubic meter/hour |

| Partial pressure | 50-1000 Pa manual and automatic pressure control |

| Operate method | manual or automatic control |

| Equipment color | customized |

View [Application of vacuum oil quenching furnace on 1.2550]

If you have any questions or requirements, please feel free to contact kevin.liu@vacfurnace.com. We look forward to hearing from you.