1. Introduction

Vacuum heat treatment is a critical process in automobile manufacturing for enhancing the performance of metal components. By heating and cooling metals in a vacuum environment, this technology improves mechanical properties and surface quality, supporting the development of lightweight and high-performance automotive parts.

2. Principles of Vacuum Heat Treatment

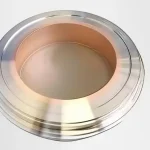

The process operates under controlled vacuum conditions (below 10⁻² Pa) and precise temperature regulation to achieve phase transformations in metals. The vacuum environment prevents oxidation, decarburization, and dimensional distortions, ensuring stable dimensions and clean surfaces for treated components.

3. Specific Applications in Automobile Manufacturing

Engine Components: Turbocharger rotors and camshafts undergo vacuum quenching to enhance high-temperature durability.

Transmission Systems: Gears and shafts are processed with vacuum carburizing or nitrocarburizing to improve wear resistance and fatigue strength.

Safety Systems: Airbag components and ABS sensors are treated to maintain reliability under extreme conditions.

Chassis and Suspension: High-strength bolts are vacuum-nitrided to increase tensile strength and reduce hydrogen embrittlement risks.

4. Technical Advantages

High surface quality: Reduced oxidation scales lower post-processing costs.

Deformation control: Uniform heating/cooling reduces deformation by 50%.

Performance enhancement: Fatigue strength increases by 25%-30% with uniform hardness distribution.

Environmental benefits: 20% lower energy consumption and reduced emissions.

5. Summary

Vacuum heat treatment provides precise control over process parameters, delivering high-performance and reliable solutions for automotive components. It is a key enabler for advancing lightweight design, electrification, and sustainability in the automotive industry.

6.FAQ

Q: What are the main advantages of vacuum heat treatment?

A: It reduces oxidation and decarburization, controls deformation, improves fatigue strength, and lowers energy consumption and emissions.

Q: Which automotive components benefit from this technology?

A: Engine parts, transmission systems, safety components, and chassis/suspension elements.

Q: How does cost compare to conventional methods?

A: Higher initial equipment costs are offset by reduced post-processing expenses and extended component lifespan.

Q: Are there material restrictions?

A: High-alloy steels require adjusted process parameters to ensure complete carbide dissolution.

Q: What are future trends?

A: Smart manufacturing integration, sustainable material adoption, and circular economy practices.