Core Characteristics of Mold Steel

In mold manufacturing, D2, H13, and H11 mold steels, due to their excellent mechanical properties, have become the core materials of choice for both cold and hot work molds. However, the quenching and hardening process for these three types of steels places extremely high demands on the process—D2 steel requires a balance between high hardness and low deformation, H13 steel requires a balance between thermal crack resistance and toughness, and H11 steel requires stable thermal fatigue properties. Traditional quenching equipment often struggles to fully realize the material’s potential due to issues such as oxidation decarburization and uneven cooling.

Core Advantages of the SIMWU Vacuum Gas Quenching Furnace for Die Steel Quenching

The vacuum gas quenching furnace provides precise quenching tailored to the performance requirements of three types of steel. Its specific advantages are as follows:

1.High Vacuum Environment: Zero Oxidation and Decarburization, Ensuring Surface and Composition Stability

The equipment utilizes a high-power vacuum pump system capable of maintaining a minimum vacuum of 10-1 Pa. Oxygen and reactive gases are eliminated from the furnace throughout the quenching process, significantly reducing oxidation and decarburization. Field tests have shown that after quenching a D2 mold in the vacuum gas quenching furnace, the surface is free of oxide scale, allowing direct access to subsequent grinding processes. The chromium retention rate on the surface of H13 steel reaches 99.5%, preventing the formation of a “chromium-depleted layer” and improving corrosion resistance by over 20%.

2.Staged Temperature Control + High-Pressure Air Cooling: Customized Cooling, Balancing Performance and Deformation

The equipment is equipped with a multi-zone independent temperature control system, enabling precise temperature ramping curves tailored to the characteristics of the steel. For D2 steel, staged temperature ramping is used to prevent cracking caused by thermal stress. For H13 and H11 steels, an isothermal holding process is used to promote uniform carbide precipitation and enhance thermal crack resistance.

The cooling process utilizes high-pressure inert gas (nitrogen/argon) for rapid cooling, with the cooling rate adjustable in multiple steps via gas pressure and fan speed.

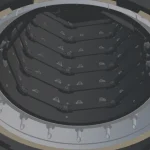

3.Uniform Flow Field Design: Temperature Variation <±5°C, Ensuring Batch-to-Batch Consistency

The heating elements within the heating chamber are evenly distributed 360° around the chamber’s circumference, creating a uniform 360° flow field for the inert gas. Temperature variations within each zone within the furnace are strictly controlled within ±5°C. This solves the problem of “different quality within the same furnace” with traditional equipment, significantly improving production stability for mold manufacturers.

4.The temperature controller uses a Continental controller. Its control accuracy reaches ±0.5‰ F.S., helping users achieve the highest level of process quality. This temperature controller boasts powerful communication and expansion capabilities, enabling at least 20 (expandable) temperature/time settings, intelligent PID control, automatic switching of heating control channels, and many other functions. It also provides redundancy for thermocouple burnout, streamlining troubleshooting and improving equipment reliability during production.

5.All low-voltage components are from international brands such as Siemens, Schneider, and Phoenix Contact, ensuring exceptional quality, performance, and workmanship. This reduces control system failure rates. If a component fails after long-term use, users can quickly identify the faulty component, further mitigating losses.

6.Motion control is provided by a Siemens programmable controller, and interlocking protection is implemented for the equipment’s vacuum pump, valves, heating power supply, cooling fan, and other components.

7.Equipped with a material cart, it facilitates workpiece loading and unloading.

Unleashing the performance of D2, H13, and H11 mold steels requires precise and efficient quenching equipment. The SIMUWU vacuum quenching furnace, with its technological advantages of “zero oxidation, controllable, and highly uniform,” provides mold companies with a comprehensive solution from process design to equipment operation. In the future, SIMUWU will continue to deepen its vacuum heat treatment technology and develop customized processes for more specialized steels, helping the mold industry break through manufacturing bottlenecks and move toward a new stage of high-quality development.

For detailed equipment specifications or customized quenching solutions, please visit the SIMUWU vacuum furnace official website (www.simuwufurnace.com) or contact us by email at kevin.liu@vacfurnace.com.