Application of Vacuum Gas Quenching Furnaces for 1.2343

1.2343 is a high-quality chromium-molybdenum-vanadium alloy hot-work tool steel, internationally equivalent to the American AISI H11 grade. As a representative hot-work tool steel, its core advantage lies in its ability to operate stably for extended periods under high-temperature conditions.

Key Features:

1.High toughness and impact strength: Provides molds with exceptional resistance to chipping.

2.Outstanding thermal fatigue resistance: Withstands temperature stresses from repeated heating and cooling cycles, effectively extending mold life.

3.Good high-temperature strength and hardenability.

To achieve this high-performance mold steel, vacuum quenching and tempering are essential processes. The following outlines the vacuum heat treatment procedure for 1.2343:

1.Primary Preheating: Heat to 600°C to 650°C and hold in vacuum or nitrogen atmosphere (stress relief).

2.Secondary preheating: Raise temperature to 800°C to 850°C and maintain holding time (for temperature homogenization).

3.Austenitizing heating: Raise temperature to 1000°C to 1040°C and hold for 30-60 minutes under high vacuum (approximately 10⁻³ Pa).

4.Vacuum Quenching: Rapidly cool while injecting high-purity nitrogen (N₂) at 2 bar to 10 bar.

5.Final Cooling: Must be continuously cooled to room temperature (below 50°C) to ensure complete martensitic transformation.

First tempering: Hold at 550°C to 620°C for over 1 hour (stress relief).

6.Intermediate cooling: Fully cool the workpiece to room temperature again (critical step to ensure residual austenite transformation).

7.Second tempering: Hold at the same temperature as the first tempering for over 1 hour (achieve final properties and toughness).

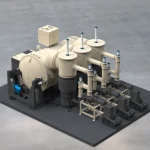

The following are the technical parameters for the vacuum gas quenching furnace used in the vacuum gas quenching and tempering of 1.2343 :

| Furnace type | Horizontal type,single chamber, internal recycle |

| Loading method | Front loading |

| Effective working zone | 800×800×1200(W×H×L mm) |

| Max. loading weight | 1000kg (including jig) |

| Power supply | 3Phase 380V(±5%) ;50Hz |

| Total power | 370kw |

| Heating power | 320kw |

| Cooling fan motor power | 280kw |

| Max.design temperature | 1300℃ |

| Working temperature | 1250℃ |

| Temperature uniformity(vacuum and empty furnace, 500-1000℃( | 9 points temp testing ( ±5℃) (standard AMS 2750F) |

| Temperature control accuracy | S-type thermocouple ±1℃ |

| Quantity of heating zone | 2-zone temperature control |

| Heating element | High-purity graphite |

| Heating rate(the room temperature of the empty furnace rises to 1200℃) | 0~20 ℃/min (Adjustable) |

| Ultimate vacuum(empty furnace, cold state, after drying and degassing) | 6.7×10-3 Pa |

| Working vacuum (empty furnace, room temperature) | 1 x 10-2 Pa |

| Evacuation time (after diffusion pump preheating, empty furnace, cold state, to working vacuum) | ≤ 45 min |

| Pressure rise rate (empty furnace, cold state) | ≤ 0.67 Pa/h |

| Cooling method | Air cooling/Natural cooling |

| Cooling gas | Nitrogen or Argon (purity: 99.99% or 99.999%) |

| Cooling rate ( empty furnace, 1200°C~500°C ) | ≤ 6 min |

| Max charging pressure(absolute pressure) | <15bar |

| Temperature control method | Intelligent programmable temperature controller for automatic temperature control |

| Control mode | PLC automatic / manual control interlock protection |

| Furnace shell color | Customized |

If you have any needs or inquiries, please feel free to contact us at furnace@vacfurnace.com. We look forward to serving you