Application of Vacuum Gas Quenching Furnace for Cr8 Tool Steel

1. Introduction

Cr8 (German standard 1.2360) is a medium-carbon, high chromium cold work tool steel. Its key advantage is the balance of toughness and wear resistance.

2. Main Characteristics:

● High Toughness and Moderate Wear Resistance:

This is the most significant feature of Cr8. It has much better toughness than high-carbon, high-chromium tool steels (like Cr12MoV), making it less prone to chipping or cracking under complex stresses from impact or extrusion. While its wear resistance isn’t as high as Cr12MoV, it’s sufficient for most small to medium-sized molds.

● Good Hardenability:

After quenching, the hardness is uniform, and satisfactory hardness can be achieved even with larger cross-sections.

● Low Heat Treatment Distortion:

With proper heat treatment, Cr8 exhibits minimal dimensional changes, which is beneficial for manufacturing precision molds.

● Easy to Machine:

Compared to high-carbon steels, Cr8 has better machinability and grindability.

3. Process Flow

Using a SIMUWU vacuum quenching furnace for heat treatment of Cr8 (1.2360) tool steel can achieve excellent performance while minimizing oxidation and decarburization. Here are the detailed process steps and parameters.

Preheating (650 ℃) →Preheating (850℃)→Austenitizing (980℃-1010℃)→High-Pressure Nitrogen Gas QuenchingTempering (two or more times)

● Preheating

Preheating is a critical step in vacuum quenching. It helps to reduce thermal stress in the workpiece during high-temperature quenching, preventing cracking and deformation.

First Preheating: Raise the furnace temperature to 600-650℃ and hold for 60-90 minutes.

Second Preheating: Raise the furnace temperature to 800-850℃ and hold for another 60-90 minutes.

● Austenitizing

This is the core step that determines the final hardness and microstructure.

Rapidly raise the furnace temperature from the preheating temperature to 980-1010℃. This is the common quenching temperature range for Cr8.

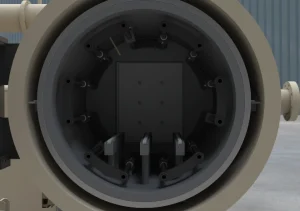

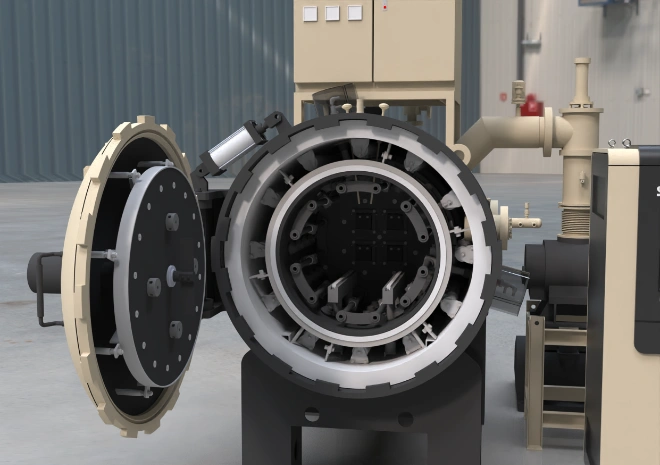

● Quenching and Cooling

A vacuum quenching furnace typically uses high-pressure nitrogen gas for cooling.

After austenitizing, turn off the furnace heating and immediately introduce high-pressure nitrogen gas for quenching.

● Tempering

Tempering is essential for relieving quenching stress and achieving the final hardness. Cr8 typically requires two or more high-temperature tempering cycles.

First Tempering: Heat the workpiece to 500-550℃, hold for 2 hours, then air cool.

Second Tempering:After the workpiece has completely cooled, repeat the first tempering step: reheat to 500-550℃, hold for 2 hours, then air cool.

Tempered Hardness:The final hardness can usually reach 58-62 HRC.

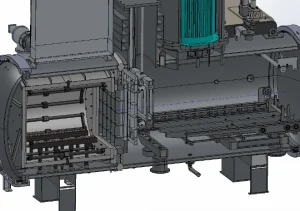

4. SIMUWU vacuum gas quenching furnace parameters for Cr8 tool steel:

| Furnace Type | Horizontal type,single chamber, internal recycle |

| Loading Method | Front Loading |

| Effective Working Zone | 800*800*1200 (W×H×L mm) |

| Max. Loading Capacity | 1000kg (including jig) |

| Power Supply | 3 Phase 380V(±5% );50Hz |

| Total Power | 210kw |

| Heating Power | 160kw |

| Cooling Fan Motor Power | 200kw |

| Max. Design Temperature | 1350℃ |

| Max. Working Temperature | 1250℃ |

| Working Vacuum | 6.7×10-2pa |