Introduction

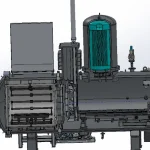

How Vacuum Furnaces Work in Semiconductor Manufacturing

1. Vacuum Environment Creation

Vacuum furnaces create a low-pressure environment by evacuating air and other gases from the chamber. This is achieved using high-performance vacuum pumps that can reach pressures as low as milli-Torr or lower. By maintaining a vacuum, these furnaces prevent oxidation and other chemical reactions that could damage the wafer’s surface or alter its properties.

2. Temperature Control Mechanisms

Precise temperature control is crucial in semiconductor processing. Vacuum furnaces employ advanced heating elements and temperature sensors to maintain uniform temperature distribution across the wafer. This uniformity is especially important for processes like annealing, where consistent heating is key to achieving evenly distributed material properties.

3. Process Gas Management

In some semiconductor processes, specific gases are introduced into the vacuum chamber to facilitate chemical reactions. For instance, during oxidation, oxygen is used to form a thin oxide layer on the wafer’s surface. Vacuum furnaces are equipped with gas injection systems that allow precise control over the type and concentration of gases, ensuring optimal processing conditions.

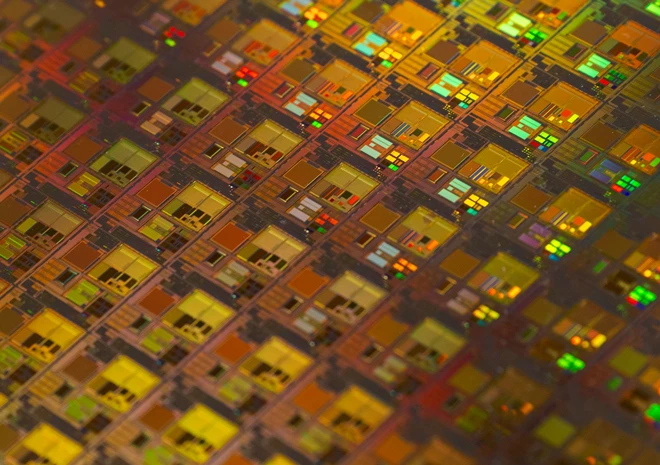

Key Applications in Semiconductor Wafer Processing

1. Annealing

Annealing is used to relieve stress in the wafer, improve its crystal structure, and activate dopants. Vacuum furnaces create an ideal environment for annealing by minimizing contamination and ensuring uniform heating, resulting in enhanced material properties and device performance.

2. Diffusion and Doping

Diffusion and doping are critical processes where impurities are introduced into the silicon wafer to alter its electrical properties. Vacuum furnaces allow precise control over diffusion, ensuring the even distribution of dopants and achieving the desired electrical characteristics.

3. Oxidation and Nitridation

Oxidation and nitridation processes are essential for forming insulating layers on the wafer’s surface. These layers are necessary to isolate different components of the semiconductor device. Vacuum furnaces provide a clean, controlled atmosphere for these processes, producing high-quality oxide and nitride layers.

4. Sintering of Metal Contacts

Sintering is used to form metal contacts on the wafer, which connect the semiconductor device to external circuits. Vacuum furnaces ensure precise control over sintering, guaranteeing high-density, low-porosity metal contacts that enhance electrical conductivity and device reliability.

Advantages of Using Vacuum Furnaces

1. Minimizing Contamination

The vacuum environment significantly reduces the risk of contamination from airborne particles, moisture, and other impurities. This is crucial in semiconductor processing, where even the smallest amount of contamination can lead to device failure or degraded performance.

2. Enhanced Process Precision

Vacuum furnaces provide exceptional control over temperature, pressure, and gas composition, allowing for highly accurate, repeatable processes. This precision is vital for maintaining consistent material properties and ensuring optimal device performance.

3. Improved Material Properties

The controlled environment in vacuum furnaces allows for the formation of high-quality layers and structures, leading to improved electrical, mechanical, and thermal properties of the semiconductor devices.

4. Energy Efficiency

Vacuum furnaces are designed with energy efficiency in mind, featuring advanced insulation and heating systems that minimize heat loss and reduce overall energy consumption. This is important for lowering manufacturing costs and minimizing the environmental impact.

Challenges and Limitations

1. Equipment Cost and Maintenance

Vacuum furnaces are complex and expensive pieces of equipment. They require regular maintenance to ensure peak performance. The high cost of acquisition and upkeep can be a significant barrier for some manufacturers.

2. Process Complexity

Semiconductor processing in vacuum furnaces involves multiple stages that require precise control over various parameters. This complexity can make optimization challenging and necessitate specialized knowledge and expertise.

3. Material Compatibility Issues

Not all materials are compatible with vacuum furnace processing. Some materials may react with the vacuum environment or the process gases, potentially leading to undesirable chemical reactions or the degradation of material properties.

Recent Technological Advancements

1. Improved Vacuum Systems

Advancements in vacuum technology have led to more efficient and reliable vacuum pumps, capable of achieving lower pressures and faster pump-down times. These improvements enhance the overall performance and productivity of vacuum furnaces.

2. Enhanced Temperature Uniformity

New heating elements and temperature control systems have significantly improved temperature uniformity in vacuum furnaces. This ensures that the wafer is heated evenly, leading to more consistent material properties and better device performance.

3. Smart Process Control

The integration of smart process control systems, including artificial intelligence (AI) and machine learning (ML), allows for more precise and automated control of vacuum furnace processes. These systems can optimize process parameters in real time, improving efficiency and reducing waste.

Future Trends in Vacuum Furnace Applications

1. Integration with Advanced Manufacturing Techniques

Vacuum furnaces are expected to play a crucial role in the integration of advanced manufacturing techniques, such as 3D printing and nanofabrication, enabling the production of more complex, high-performance semiconductor devices.

2. Development of New Materials

The development of new materials—such as wide-bandgap semiconductors and flexible electronics—will demand specialized vacuum furnace processes to achieve the desired material properties and performance.

3. Sustainability Initiatives

As sustainability becomes a greater focus in semiconductor manufacturing, vacuum furnaces will be expected to contribute by reducing energy consumption and waste. Future developments may include energy-efficient furnace designs and the use of renewable energy sources.

Conclusion

Vacuum furnaces are essential in semiconductor wafer processing, providing the controlled environment needed to produce high-quality, reliable semiconductor devices. While challenges exist, recent technological advancements and emerging trends suggest that vacuum furnaces will continue to be a critical tool in the evolving semiconductor industry.

Frequently Asked Questions (FAQ)

Q: What is the primary function of a vacuum furnace in semiconductor wafer processing?

A: The primary function is to provide a controlled, contaminant-free environment, enabling precise temperature control and process gas management during manufacturing processes such as annealing, diffusion, and oxidation.

Q: How does a vacuum furnace minimize contamination during semiconductor processing?

A: It creates a low-pressure environment that removes air and gases from the chamber, preventing oxidation and unwanted chemical reactions that could degrade the wafer’s surface or alter its properties.

Q: What are the key advantages of using vacuum furnaces in semiconductor manufacturing?

A: Key advantages include minimizing contamination, enhancing process precision, improving material properties, and achieving energy efficiency.

Q: What challenges are associated with using vacuum furnaces in semiconductor processing?

A: Challenges include the high cost of equipment and maintenance, process complexity, and material compatibility issues.

Q: How have recent technological advancements improved vacuum furnace performance?

A: Advancements include more efficient vacuum systems, improved temperature uniformity, and the integration of smart process control systems that optimize parameters in real-time.

Q: What are some future trends in vacuum furnace applications for semiconductor manufacturing?

A: Future trends include the integration with advanced manufacturing techniques, development of new materials, and a focus on sustainability initiatives.